World Premiere: “ValuCT” Delivers New Price-Performance Model for Industrial NDT

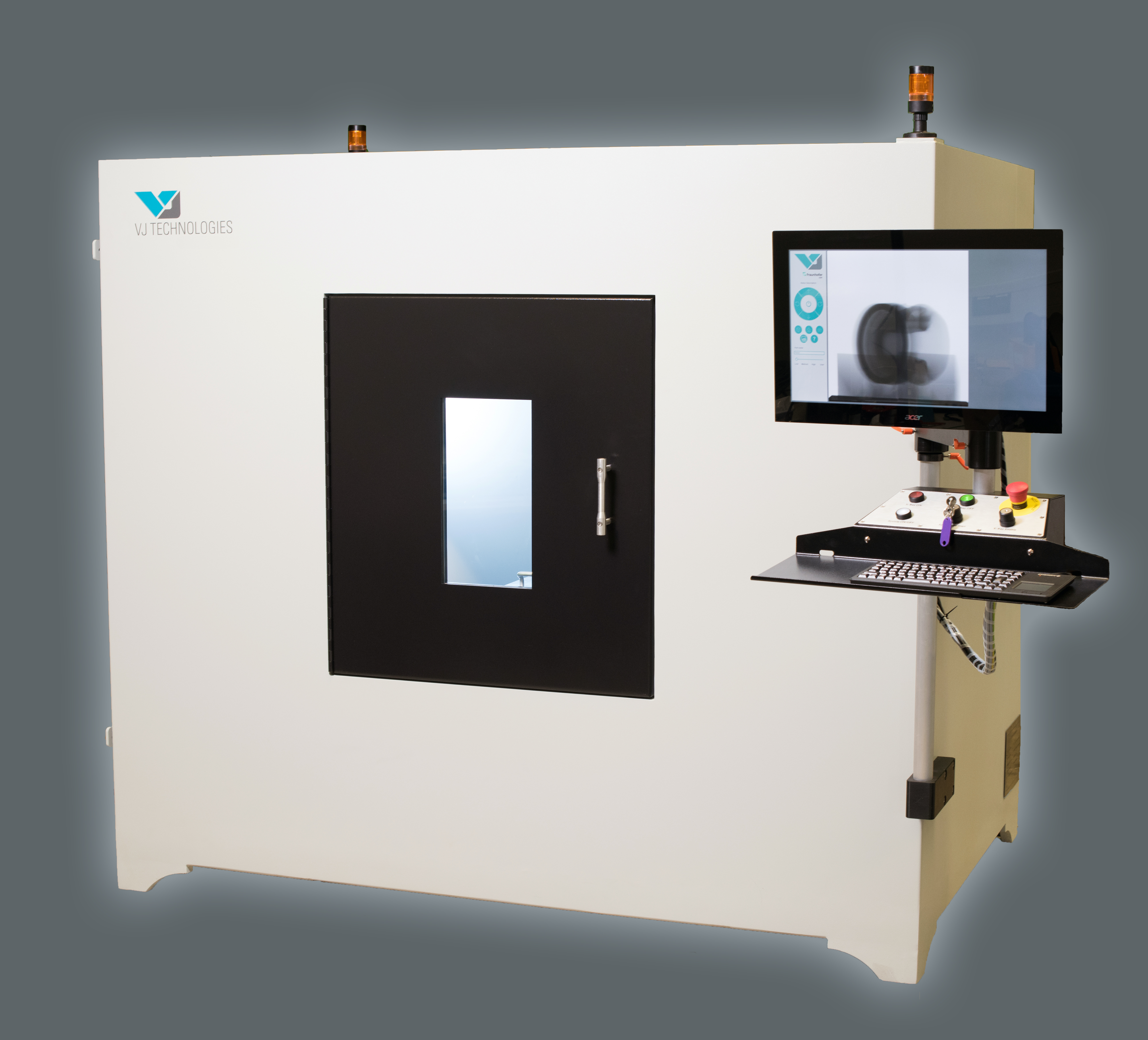

Erlangen/Munich, June 6, 2016 – WCNDT, booth no. FE 23: world premiere at the World Congress for Non-Destructive Testing in Munich: in cooperation with the American enterprise VJ Technologies the Development Center for X-ray Technology EZRT of the Fraunhofer Institute for Integrated Circuits IIS presents the cost-effective One-Click-CT System “ValuCT” The system provides two- and three-dimensional X-ray images with only one touch of a button – without any previous knowledge on the part of the user, dramatically reducing training and operating costs. The product is debuting at the WCNDT Conference in the VJ Technologies booth no. FE 23 First Floor Foyer from June 13 to 17.

Besides numerous adjustment possibilities modern single-lens reflex cameras are pro-vided with an automatic mode enabling beginners without any previous knowledge to take photographs of high technical quality. VJ Technologies and the Fraunhofer Development Center for X-ray Technology worked together to deliver this cost-effective one-click computed tomography system. “The new system is priced at the cost of traditional DR NDT systems with the ability to deliver high quality 3D CT images, it really is a breakthrough for the industry, states Vijay Alreja, CEO of The VJ Group.

Fully Functional Capabilities, Plus Simple Operations

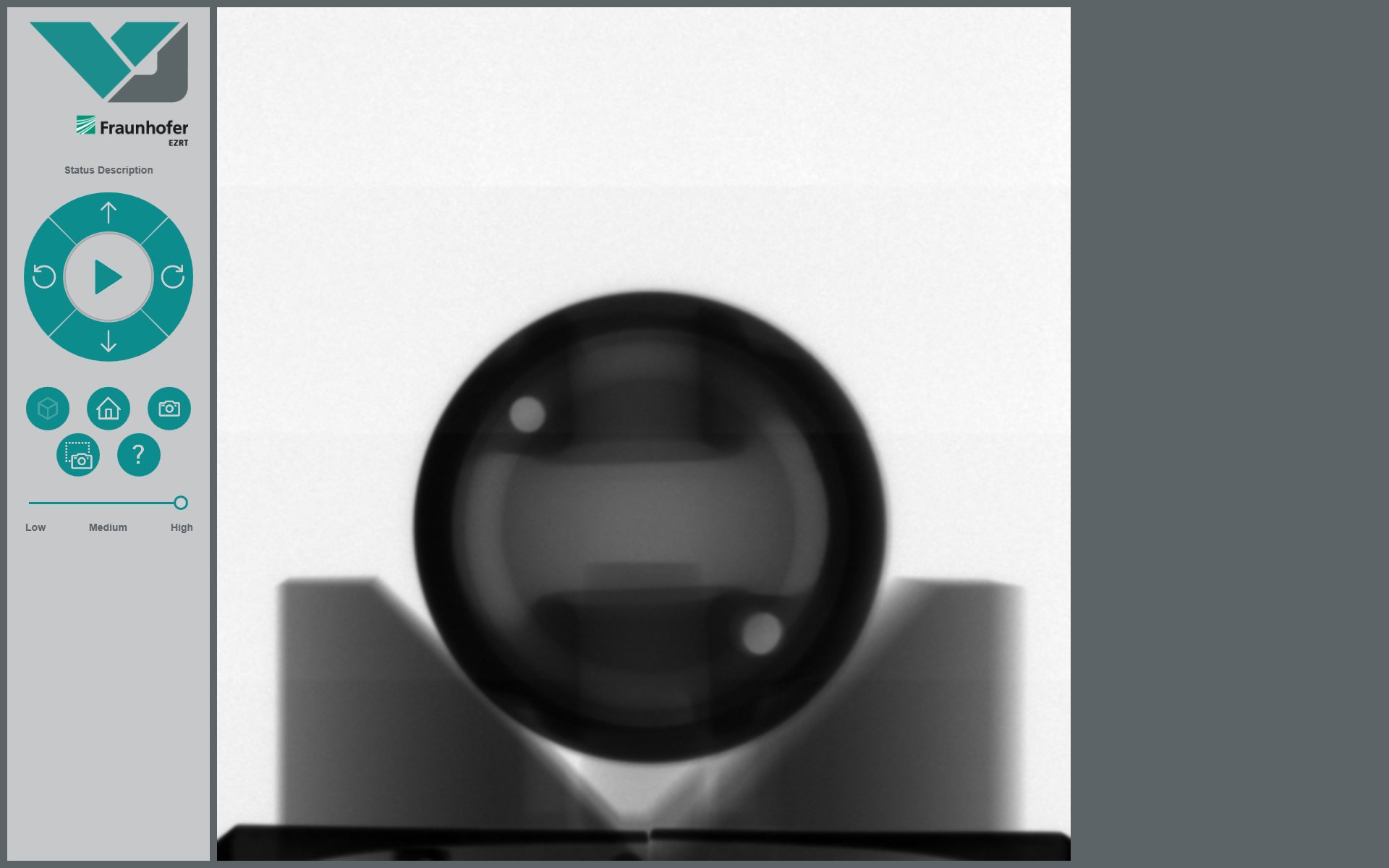

Obtaining the optimum X-ray image is a science in itself. It usually requires specialize skills and many small adjustments to achieve ideal images. The one-click computed tomography system uses new algorithms and technologies to literally “take charge” of the technical direction of all of this: an innovative user interface provides operators with easy to use predefined programs to optimize the image acquisition. Thus, the system creates images with parameters optimally adjusted to the test object, reconstructs a 3D model from hundreds of individual images and evaluates it fully automatically, in just seconds.

The maintenance-free components of the “ValuCT” are manufactured by VJ Technologies from one source and are thus optimally compatible. The X-ray source is operated at an output of 500 watts and a voltage of 180 kV together with the detector at a resolution of 190 micrometers. It is possible to examine objects of a maximum diameter of 20 centimeters at an object height of maximally 50 centimeters.

Numerous possible applications

The system is suitable for any possible application of modern X-ray technology – whether reverse engineering, precise location of faults or metrology.

In particular small and medium-sized companies of the producing industry will benefit from the “ValuCT”: “We subjected the system to extensive tests in our laboratories using CFRP or aluminum components that can be easily radiographed as test specimens. Both the test results and the data quality were constantly at a high level”, reports Markus Eberhorn, head of the group “Computed Tomography Systems”.