Acoustic condition monitoring of production systems with intelligent sensors.

In today’s production facilities, information from sensors is already used to monitor machines and systems. Until now, this condition monitoring has relied primarily on structure-borne noise signals, whereas measurements of airborne sound waves for this purpose are virtually unheard of. Although microphones could be used to record operating noise from systems to determine whether they are operating without irregularities, this approach is fraught with problems as a result of normal ambient noise.

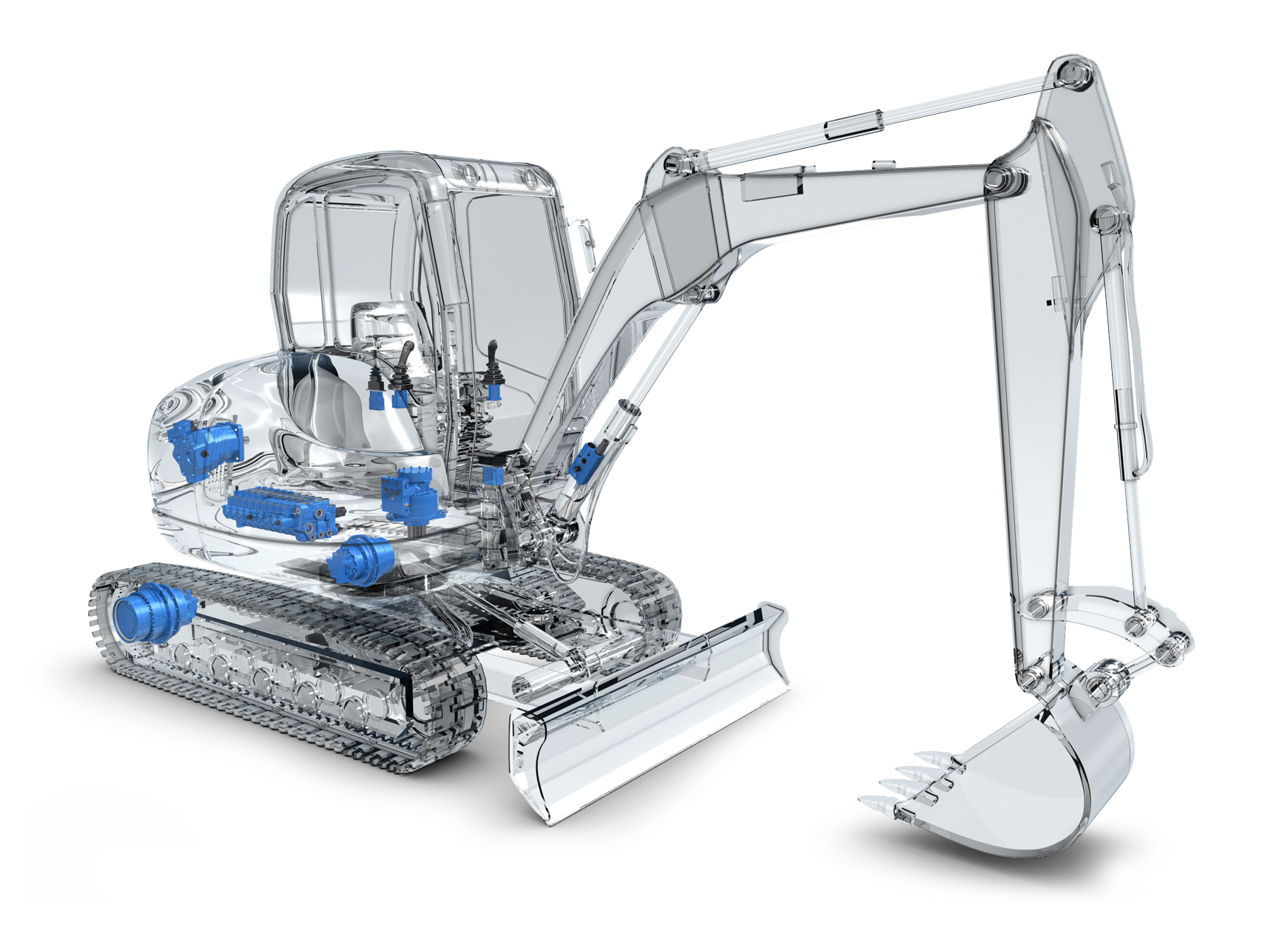

At our EAS division in Dresden, we are therefore collaborating with numerous industrial partners and the Fraunhofer Institute for Digital Media Technology IDMT to develop an affordable, easy-to-operate platform with versatile applications as part of the ACME 4.0 project. The platform will pave the way for acoustic monitoring in both industrial and mobile applications and is based on our own IC solution, which is fi tted to sensor systems that are then used in combination with complex signal processing algorithms. There are also plans to take advantage of both energy harvesting and totally wireless communication.

A compact construction and high energy effi ciency aim to ensure that the sensor system can be integrated into production facilities and mobile applications easily. The hardware can also be quickly adapted via software in order to open it up for additional use cases. To ensure that the solution can be applied in as many areas as possible, the project’s demonstrators are chosen to cover a wide range of frequencies.

Our work on the project centers around designing a dedicated hardware front end for recording microphone signals, as well as the development of signal analysis algorithms. The focus here is on designing an integrated sensor-reading circuit complete with analog-to-digital conversion. The project will also benefi t from our existing experience in the implementation of condition monitoring systems for machines and other equipment, as well as the associated signal-analysis and dataprocessing algorithms. The aim is to explore new methods of event and condition detection and to adapt these to the project’s requirements.