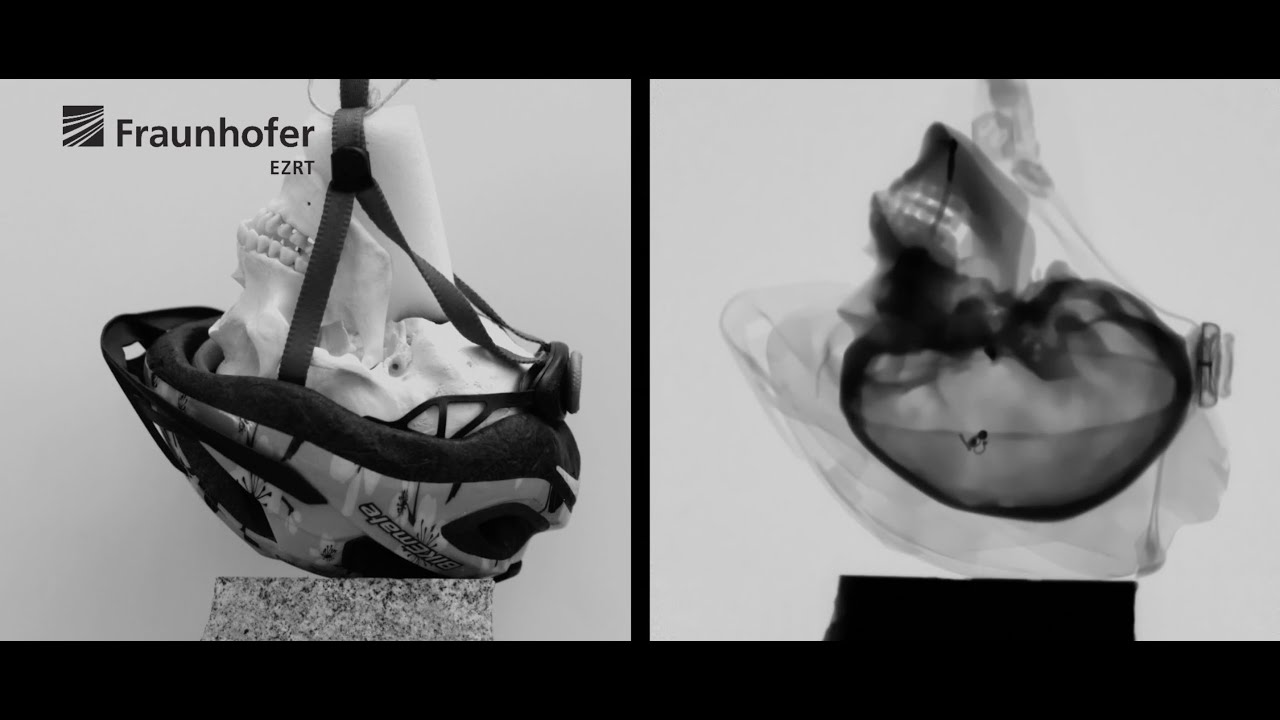

Optical slow-motion recordings provide insights into dynamic processes. But they show only processes that are actually visible; what happens inside objects during such processes remains unclear. This is where high-speed X-ray detectors come into play. The Fraunhofer Development Center for X-ray Technology EZRT is opening up completely new possibilities for analyzing dynamic processes by means of a synchronous and same-perspective combination of optical high-speed imaging and X-ray imaging.

With a loud bang, a car hits a bollard wrapped in bright warning colors. The plastic of the bumper splinters and the car body deforms, almost elegantly wrapping itself around the obstacle. In behaving as they did, the materials responded precisely as the vehicle designers intended. A meticulously prepared crash test like this is designed to demonstrate the correct engineering and safety of the vehicle – a way to show that all the previous calculations and simulations were on the mark.

To this end, the deformation of the vehicle is recorded exactly as it happened using high-speed optical cameras. Examining one image at a time, the experts can piece together how the test matches up with the calculations. Their aim is to make sure that the material on the outside of the vehicle deforms precisely as planned in order to provide maximum protection for hypothetical occupants.