At a glance

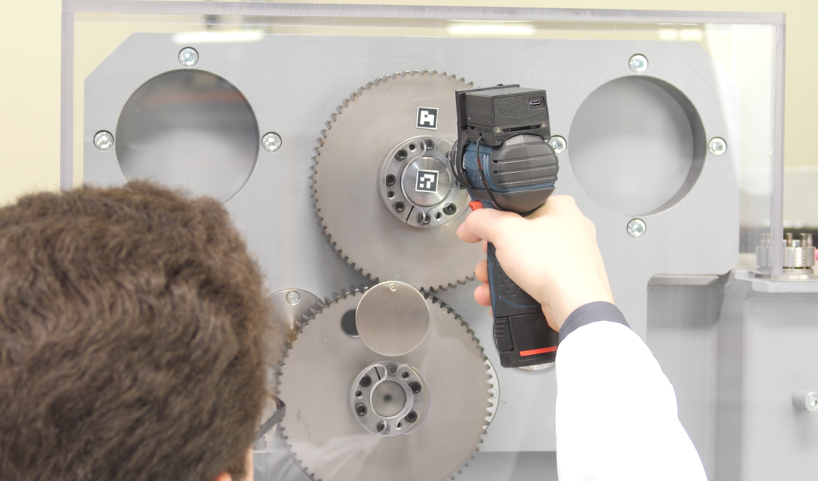

Even highly automated production involves numerous manual working processes. Technicians need to be vigilant at all times if these processes are to run smoothly, while information on the work to be done can change regularly when dealing with individualized products. When that happens, the correct use of tools is essential in order to ensure not only quality but also the safety of technicians. With this in mind, Fraunhofer IIS has developed a retrofittable and intelligent sensor module for hand tools that measures various parameters during work processes and thereby delivers process optimization, transparency, and quality assurance. Multiple sensors detect not only actions (e.g., the tightening or loosening of screws) but also the location and sequence of operations.