In times of artificial intelligence, AI-based image recognition and ChatGPT, reading fonts on products is no longer a challenge. At the end of a production chain, there is often an automated final inspection to check whether the product in question is correctly labeled. As the labels often contain safety-relevant information, the inspection requirements now go beyond mere reading, i.e. verifying the correct content: it must be ensured that the information is also clearly legible for a human. But when is a text legible? In other words: What are suitable criteria for verifying the legibility of a text?

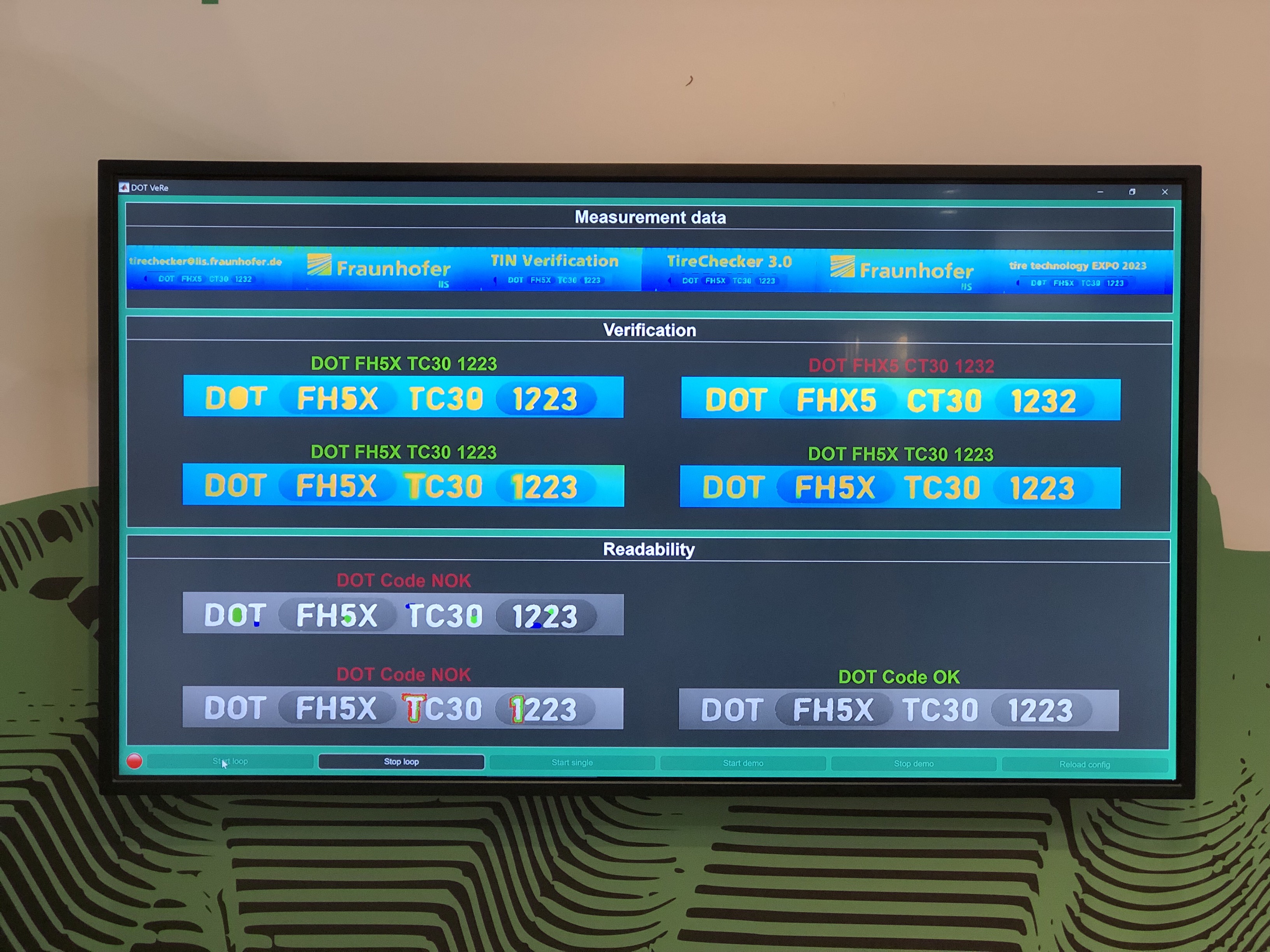

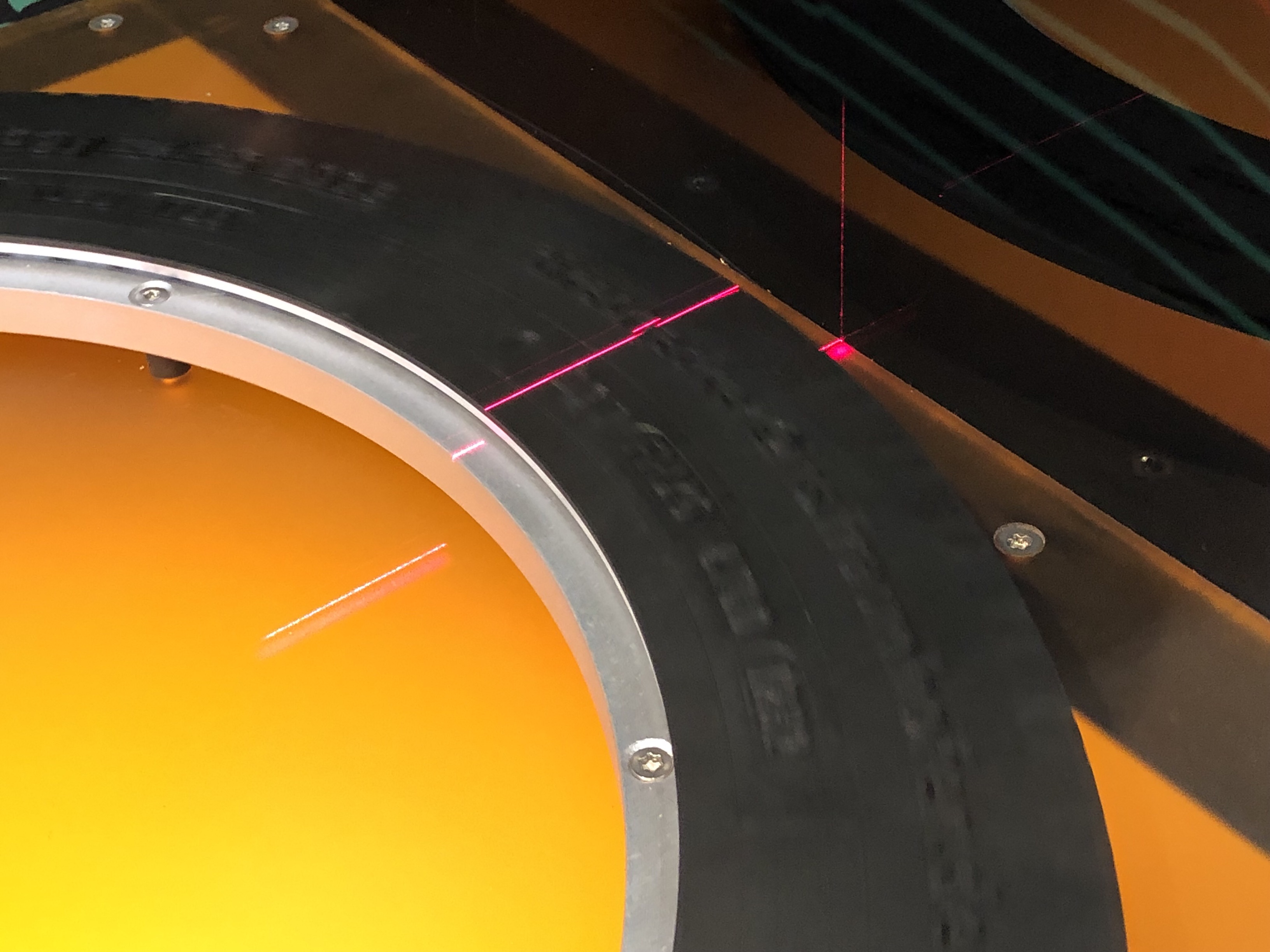

The VeRe (Verification and Readbility) software developed by Fraunhofer IIS is a prototype software for the inspection of 3D lettering that verifies whether the correct 3D lettering is displayed on a product and whether it can be read by a person. Various 3D sensors, such as the TireChecker sensor system, can be used to record the 3D lettering.

Application examples include the reading of so-called DOT or TIN codes (Tire Identification Number) on tires (see video), the reading of embossed lettering on metal parts or the identification of nest numbers on injection-molded components.