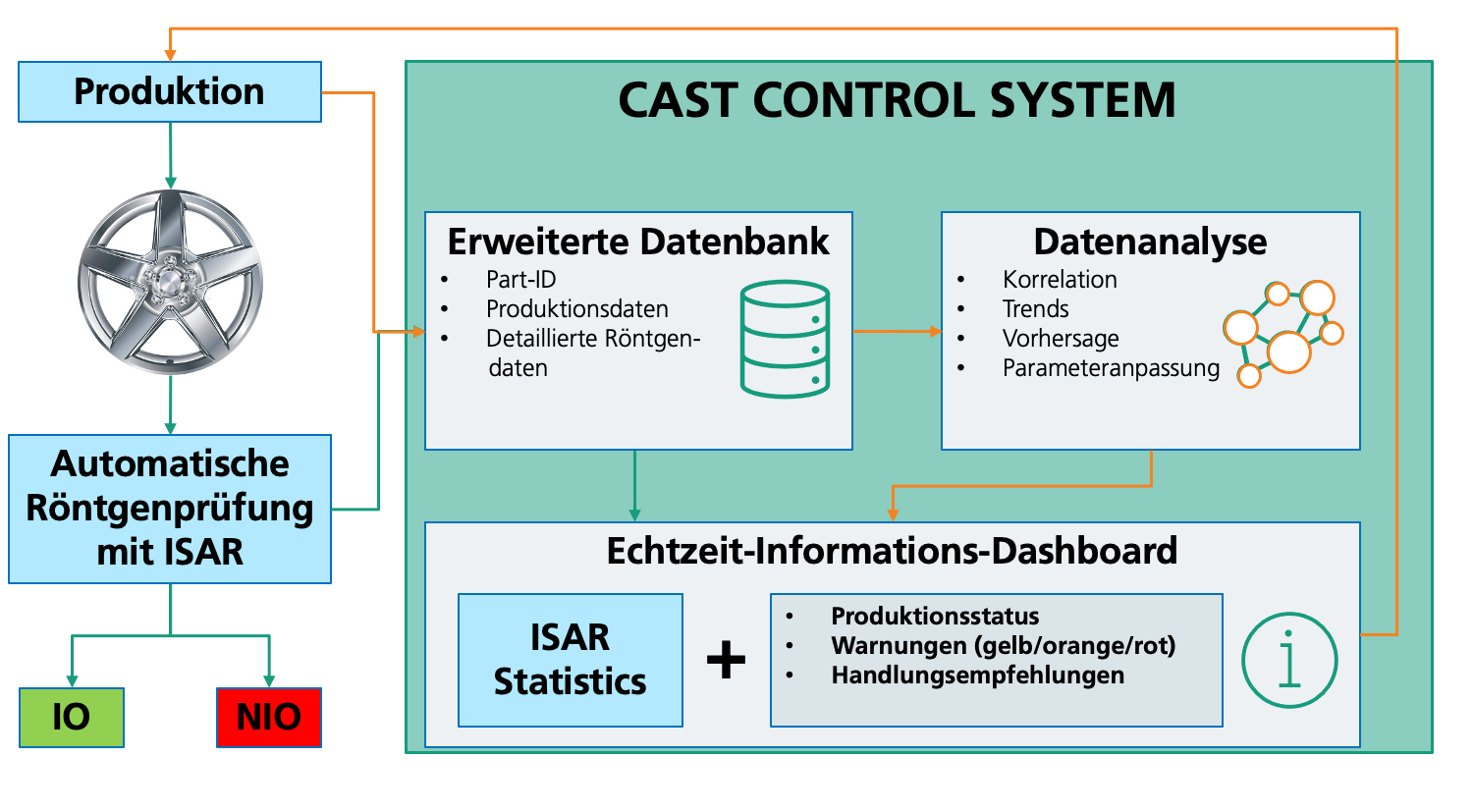

With the Fraunhofer software solution ISAR, X-ray projections of light alloy wheels can be inspected fully automatically for defects. Both classic image processing chains and machine learning methods are used for this purpose. ISAR then decides based on defined quality criteria whether a wheel is to be declared a reject. The results of the inspection are stored in a database and a statistical evaluation of the results can be visualized via the web-based tool ISAR Statistics.

In the Cast Control project, the results of the X-ray inspection were combined with the recorded sensor data from the casting process and analyzed using machine learning methods.

The Cast Control system is able to provide product quality forecasts and recommendations on which parameters of the casting process should be changed in order to improve product quality and thus reduce rejects.

The long-term goal is to create an automatic control loop as far as possible between the results of the X-ray inspection and the process parameters, so that rejects do not occur in the first place.