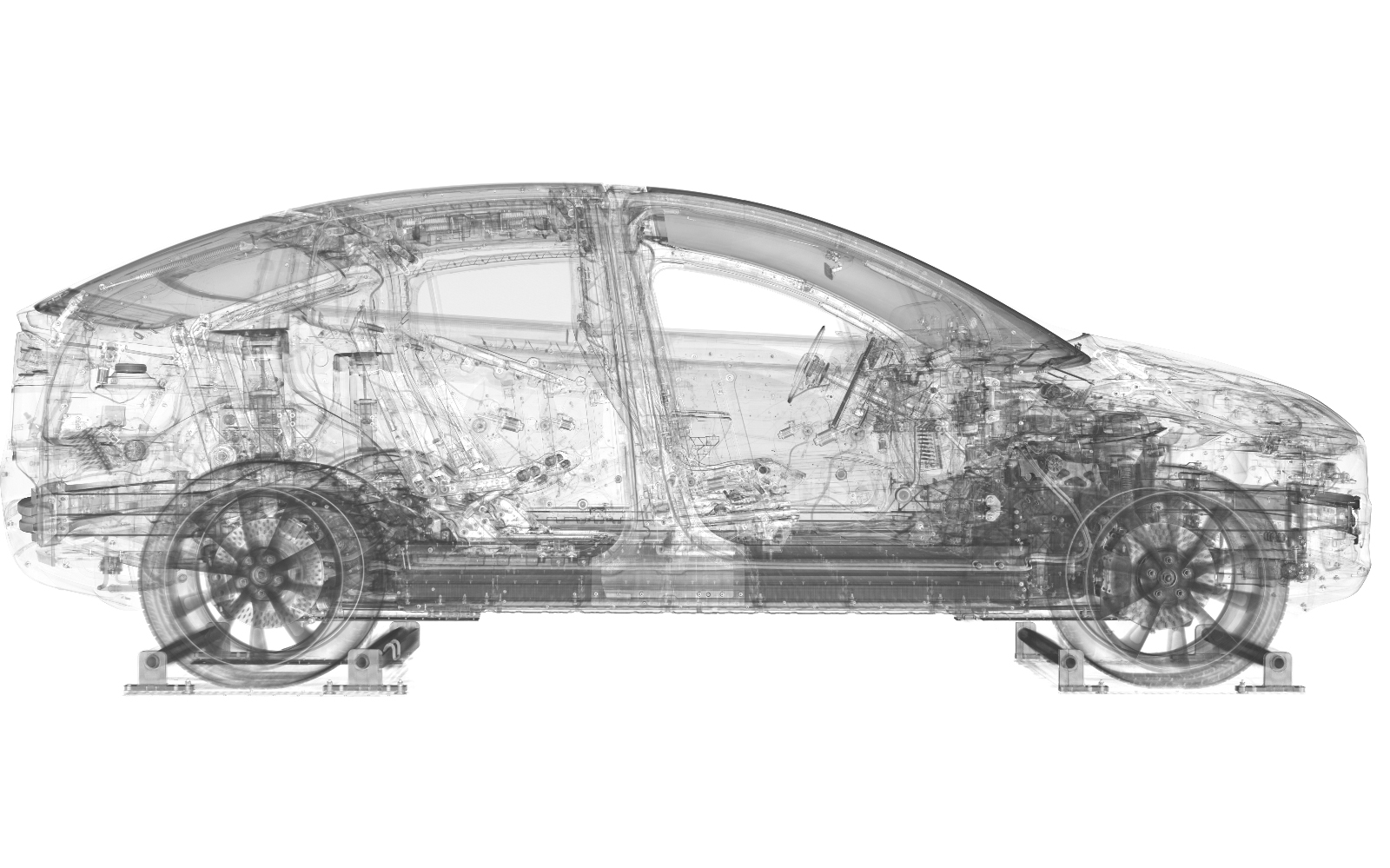

“Ensuring that batteries function safely and reliably is in everyone’s best interest. No one wants to see their car go up in flames.” While that’s undoubtedly true, what does it have to do with X-ray technology? Michael Salamon from the Fraunhofer IIS Development Center X-ray Technology describes how XXL computed tomography (XXL-CT) reveals what’s going on deep inside large objects and in unimagined detail. This is how researchers analyze battery modules and entire cars with a view to making battery technology safer and more innovative.

Reliable batteries: How XXL computed tomography is improving safety on the road and in the garage

January 31,.2023 | How can Fraunhofer IIS make battery technology safer and more innovative?

Mr. Salamon, what’s XXL computed tomography all about?

XXL-CT is a unique kind of CT system that can be used to scan energy storage solutions ranging from tiny assemblies to the entire battery module of a car. Conventional CT systems are capable of scanning individual cells at an adequate resolution, and even of examining smaller modules. But what they can’t do is analyze the large, complex assemblies in their entirety and after they’ve been installed. For smaller, more compact modules, XXL-CT can produce a resolution of one-tenth of a millimeter. When it comes to battery modules already installed in a car, that resolution is between one-half and one millimeter. That’s a service that only we at the Development Center X-ray Technology can offer.

How is this technology going to help achieve sustainable electromobility?

Developing new battery systems calls for an in-depth understanding of the processes taking place both within individual cells and in the module as a whole. While a host of process monitoring steps – up to and including the tomography of each individual cell during production – have already been implemented at the cell level, analyzing cells once they have been integrated into a battery module becomes much more complicated. A particular focus here is analyzing how energy storage systems hold up over time, for example after 100,000 kilometers. As part of complex studies, cell and module prototypes are aged artificially by running charging and discharging cycles and by simulating the driving situation using a shaker system to make the battery module vibrate.

And how do you analyze the effects of these artificial aging processes?

This is where nondestructive XXL-CT testing comes in. Our technology makes it possible to perform analyses even at intermediate stages in the life cycle. We can observe the whole process as it unfolds and without damaging the module at all. That is the major advantage and also highly relevant for new battery systems.

Ensuring the safe and reliable operation of these battery systems is in everyone’s best interests. Compared to vehicles powered by conventional engines, electric cars currently have a higher risk of catching fire, especially if the battery module is damaged as the result of a collision. This highlights why the safety, quality, and reliability of battery modules are of supreme importance for people’s confidence in electromobility and for manufacturers to maintain their image. XXLCT now offers a tool for significantly reducing the risk of such fires because it delivers meaningful data that manufacturers can use to vastly improve their safety analyses.

»That’s a service that only we at the Development Center X-ray Technology can offer«

Can this technology also be used to analyze the damage caused by a traffic accident?

Of course. But it’s still too expensive for private individuals. At present, this method is used mainly in the development of electric cars, for instance, after a crash test. In that moment, it’s impossible to look inside and see what’s happened to the various modules. In most cases, test objects simply get scrapped. One generally has to rely on simulations and experiments performed using dummy batteries. These weigh exactly the same as the real thing, but it’s safe to cut them open for analysis. However, while such conventional methods can examine whether all the cells are still intact and in the right place, they can’t do it in the high resolution offered by XXL-CT. No one else in the world offers what we do.

At present, industrial customers have to come to the location in Fürth to use the technology. Are you also planning to deliver it to customers?

Definitely. We have a partner company in place to market our technology directly and provide turnkey systems. The interest is definitely there. Our next step will be to integrate the application as much as possible into development and production processes to really tap the added value it offers. To this end, we’re planning to expand our range of services and make it easier for frequent users to access the technology through framework agreements. This is how we hope to move beyond what is now often more of a one-off forensic exercise and establish our technology as a standard tool.

Are there any customers that have rolled out XXL-CT on their own?

We’ve been working on this technology for 13 years. In that time, a number of companies have followed in our footsteps and are now offering similar technologies – but in smaller sizes. So I feel confident in saying that it was our idea that launched the XXL high-energy CT market in the first place.

What is your vision for the future?

Looking ahead, developing the technology further to produce a gantry CT is what will open up an even larger market. By “gantry,” we mean a tube-shaped CT scanner, like those used in the medical field. Today, long objects such as cars or battery modules are placed upright for analysis. But a future gantry CT would scan these objects in their natural position, which also minimizes the effort and risks associated with handling test objects.

Ultimately, we’d like our work to have benefits that extend beyond just quality assurance. Especially when it comes to developing new batteries and modules for electric vehicles, we’d like to furnish the Germany automotive industry with a new tool that helps make products even better and safer. After all, the high standards characteristic of German automakers are and will remain key to Germany’s success as an automotive powerhouse.

Mr. Salamon, thanks for talking to us.

Interview by Lucas Westermann, Editor Fraunhofer IIS Magazin