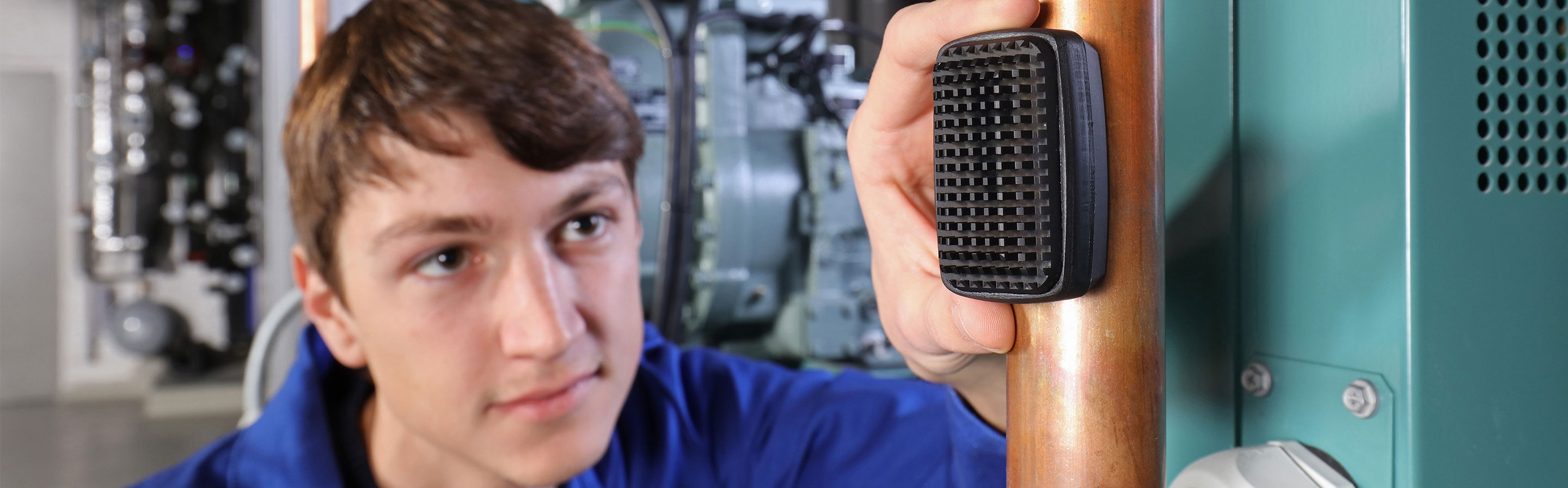

BlueTEG Pipe: Energy for the industry

The Fraunhofer Institute for Integrated Circuits IIS has developed the sensor BlueTEG Pipe with thermoelectric power supply for industrial applications. BlueTEG Pipe uses the temperature difference between warm or cold objects and the environment for energy. Integrated in a compact housing, the sensor measures values such as the ambient temperature or acceleration rates and sends them to a tablet via Bluetooth.