At Fraunhofer IIS, Tobias Dräger develops solutions for Industry 4.0 processes. Intelligent implementation of inductive near-field positioning together with an armband creates a system that reports problems immediately, which in turn makes manual picking processes less prone to error. We talked to Tobias Dräger about how this assistance system works.

Error-free processes with the picking armband and near-field positioning

November 12, 2021 | Tobias Dräger explains how order pickers are using near-field positioning to detect mistakes.

How inductive near-field positioning is helping order pickers avoid errors

Why do you see the need to improve manual picking processes at companies?

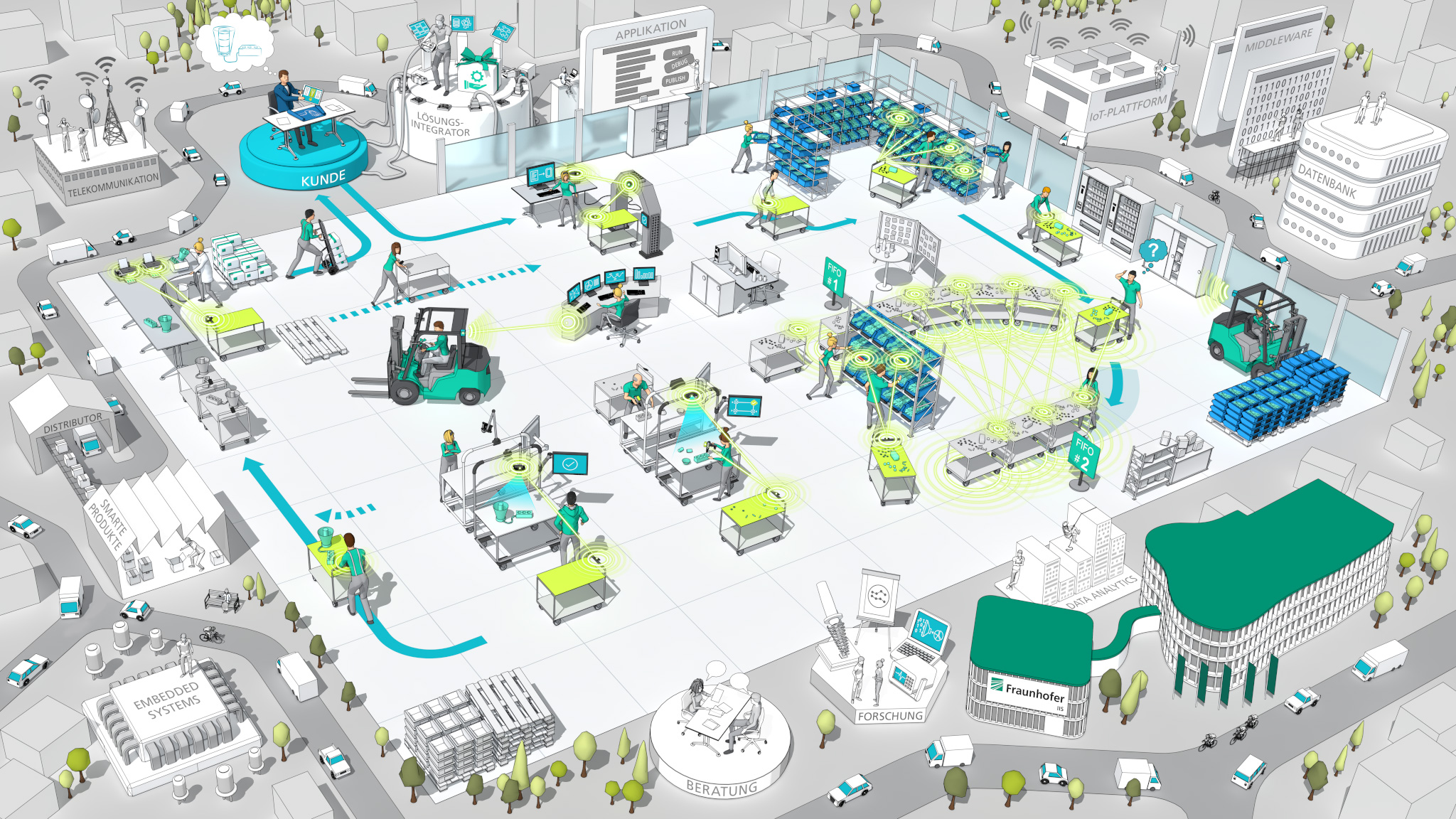

Dräger: Making mistakes is part of being human. At many companies, most orders are put together by people. Manual picking processes leave room for errors, some of which can affect a company’s performance. At Fraunhofer IIS, we developed IndLoc – our near-field positioning technology – to prevent such things from happening.

How does the near-field positioning system work?

Each order picker is issued with a wearable, like a glove or an armband, and IndLoc tracks its movements. We create a weak magnetic field around each shelf. When the order picker reaches into a compartment on the shelf, the magnetic field changes. The software automatically recognizes which compartment it was and checks whether it was the right one for the order. IndLoc can determine the position of movements with extremely high precision. If the picker reaches into the wrong compartment, they immediately receive an alert as well as a correction suggestion.

There are other systems that use LEDs to indicate the correct compartment. What’s so special about the inductive near-field positioning you’ve developed?

Ours doesn’t rely on the scanning processes the picker would otherwise have to use to confirm that an item has been picked. Since the armband is equipped with only a passive coil, similar to a traditional RFID transponder, the object to be positioned doesn’t need its own power source. This is the USP of our near-field positioning technology. What’s more, the positioning system can be easily retrofitted and tailored to the specifics of a company’s site. And it doesn’t have to be a shelf; the monitored area can be a wide range of sizes and shapes.

Where can the positioning system be used?

We’re refining IndLoc so that in addition to enhancing picking processes, it can be used to recognize material and bulk goods. We can now determine not only how full a box is, but also whether it contains, say, screws with an M5 or M4 thread. The technology could also be used to identify other conductive objects such as various electronic components.

About Tobias Dräger

Tobias Dräger studied electrical engineering with a specialization in automation/sensor technology at Friedrich-Alexander-Universität Erlangen-Nürnberg in Germany. He joined the staff at the Fraunhofer Institute for Integrated Circuits IIS in 2007, focusing on RFID and embedded hardware as well as on wireless transmission technologies. In 2018, he was appointed manager of the RFID and Inductive Sensor Systems group, which in addition to researching the topics of embedded hardware, wireless energy transmission, NB-IoT and RFID, also works on IndLoc® inductive near-field positioning technology.