Fraunhofer IIS at VISION trade fair to showcase powerful image processing platform and polarization camera for measuring stress in glass products

Erlangen, October 21, 2014 – VISION booth 1G42: VISION is the world’s leading trade fair for image processing and will be held in Stuttgart November 4-6, 2014. The Fraunhofer Institute for Integrated Circuits IIS will be showcasing two pioneering products there: the Vempire® embedded platform and the POLKA polarization camera. Both technologies are robust, capable and suited to a range of applications – meaning they can give companies in industry the critical competitive edge they need.

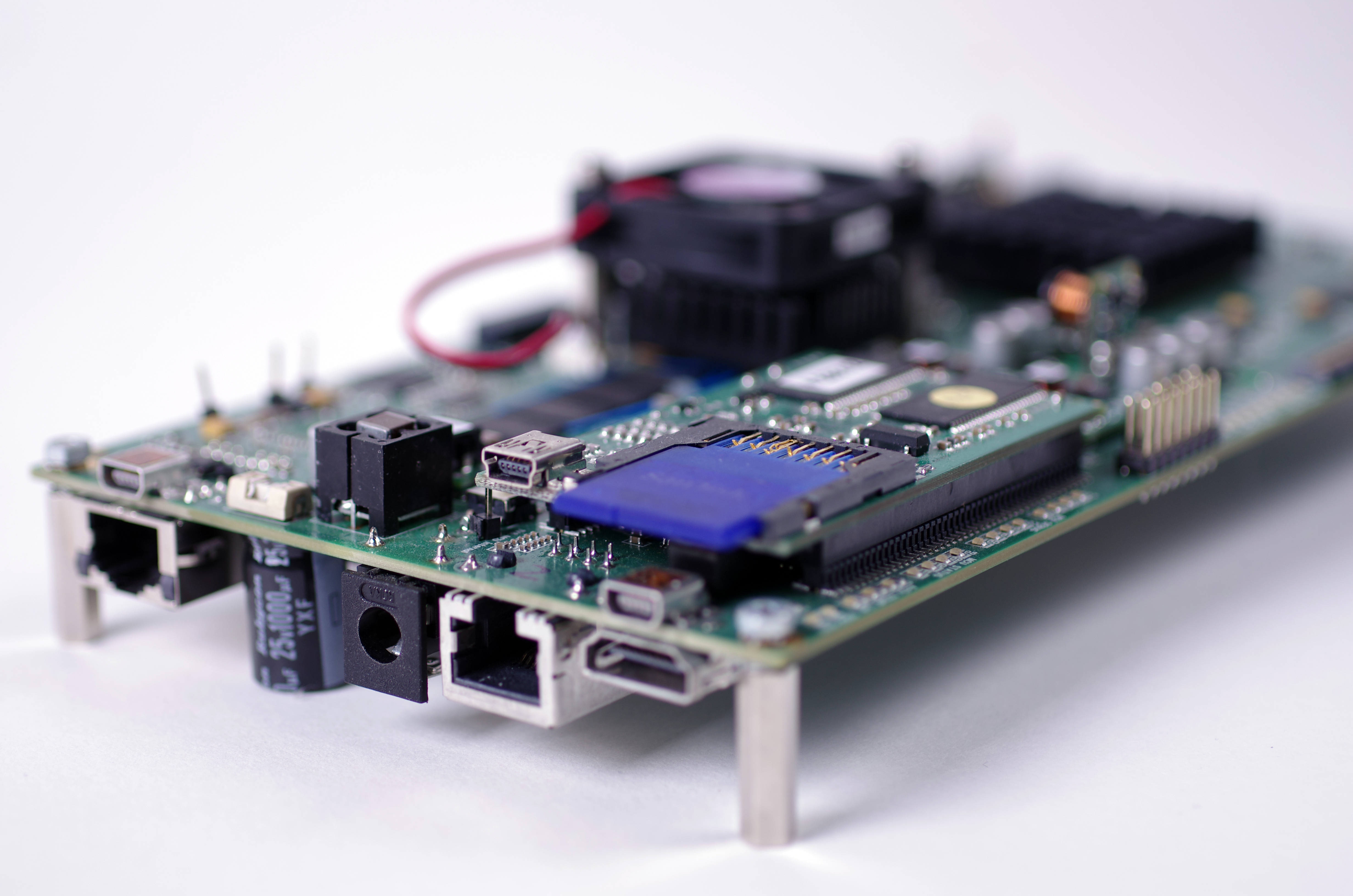

Vempire® – a mobile all-rounder for industrial image processing

Vempire®has been designed to process large quantities of data from a variety of imaging sensors without the need for a PC. In addition to its exceptional processing power, the platform also stands out for its flexible system concept, which makes it suitable for a range of applications. A compact design ensures Vempire® is the ideal solution in any situation where limitations of space or power rule out a PC, or where the application calls for particular mobility. Potential applications for Vempire®include measurement and testing technology, medical technology and media production.

At Vision 2014, Fraunhofer IIS will be showing the Vempire® platform in action in two potential applications:

• As part of a time-of-flight camera (TOF), whereby the raw data from a TOF sensor is processed in real time to provide a depth map and point cloud. This then forms the basis for calculations that bring together a range of image analysis functions, the results of which are displayed as a live image in multiple views.

• As part of a polarization camera that works in tandem with a polarization sensor to determine the polarization parameters of incident light in real time (angle and degree of polarization), with results displayed in the form of a color map.

FPGA and multicore signal processor guarantee sufficient processing power

Both of the above applications call on just a fraction of the system’s processing power. This leaves the option to implement still more image analysis functions, including sensor data fusion. Digital signal processing and analysis are further potential applications for the platform.

Vempire® is built on a high-performance FPGA and a fast multicore signal processor. This gives it sufficient processing power to handle demanding image processing algorithms in real time. There are a huge variety of interfaces on offer, e.g. Gigabit Ethernet, GigE Vision and HDMI, as well as a modular, high-bandwidth sensor frontend that can be adapted to almost any imaging sensor with a minimum of effort.

Fraunhofer IIS offers Vempire® as a system concept that can be tailored and developed to meet specific applications and individual needs. The version on display is a trade-off between performance and compactness, but Fraunhofer IIS has designed multiple versions, including for low-power applications and embedded high-performance computing with several multicore signal processors. All the concepts are based on the Vempire® system on display; this means that they can be implemented relatively quickly, since important parts of the hardware structure and firmware are already in place.

For more information about Vempire®, please visit:

http://s.fhg.de/Vempire

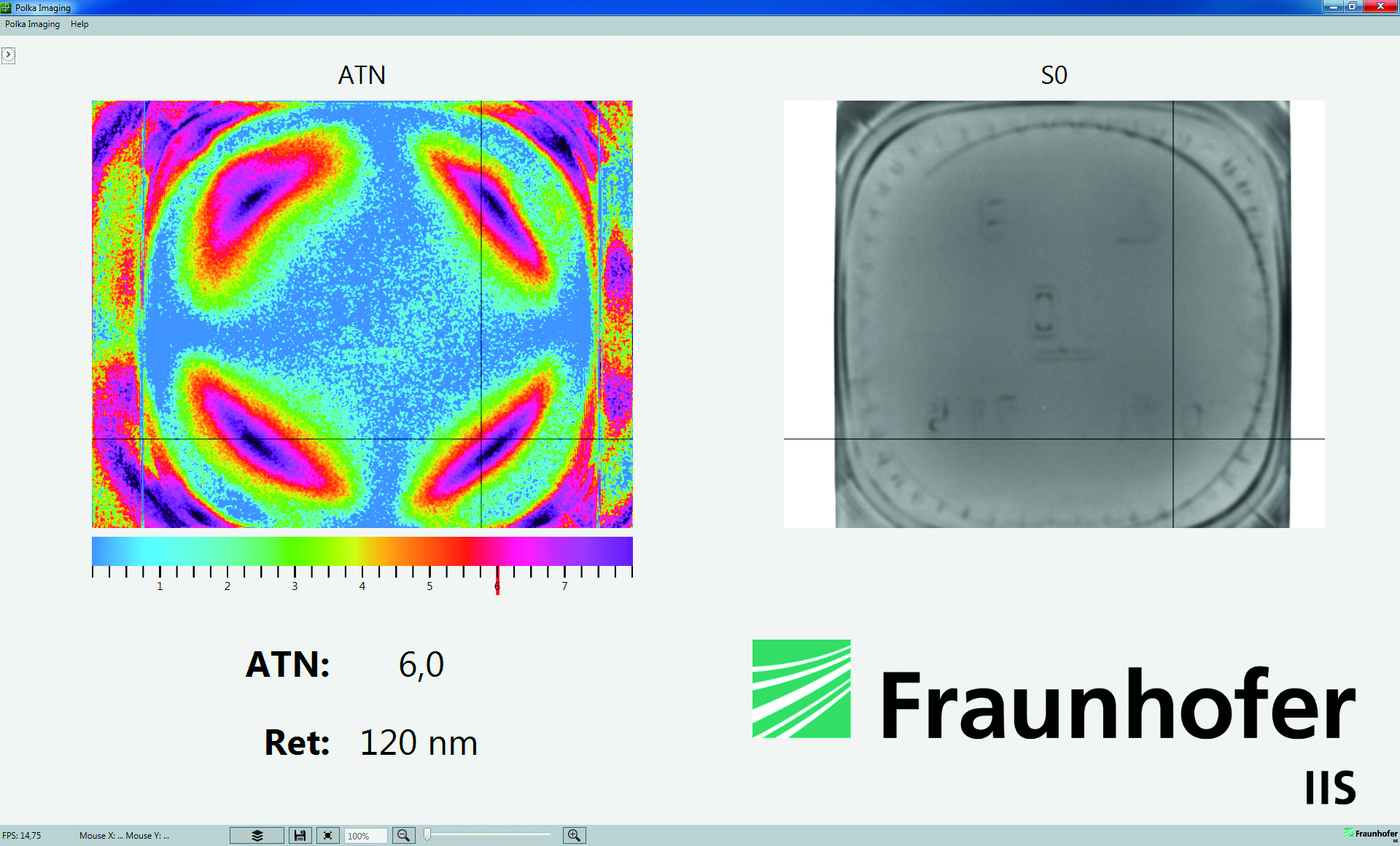

POLKA camera inspects a range of bottles in real time

One important application for imaging polarimeters such as POLKA is quality control in the manufacture of glass products. Pixel-resolution polarization measurements help capture all the polarization parameters in a single shot. POLKA helps measure residual stresses in glass containers, bottles and other glass products – and that provides a targeted method for rejecting items that might smash due to excess stress either at the filling plant or on the way to the end customer.

Imaging polarimeters also help identify discrepancies in the manufacturing process early on so that users can step in and make changes to the relevant process parameters, improving production efficiency. POLKA’s combination of hardware and software allows for the analysis of measurement results, with clear visualization that quickly flags problem areas in the glass. Stresses in the glass are shown as apparent temper numbers. Software interfaces make it easy to use the camera and to transfer the processed measurements. As a result, POLKA is simple to integrate into optical inspection systems and the results can be conveniently archived.

Further applications include the production of carbon-fiber-reinforced plastic (CFRP) components. POLKA offers a simple way of measuring the orientation of the carbon fibers.

The POLKA polarization camera is based on a novel image sensor developed by Fraunhofer IIS. With the unique design of this CMOS sensor, the camera captures all the relevant polarization parameters of light (angle and degree of polarization) in one single shot. With its high read-out rate of up to 50 frames per second, the camera is well suited for inline inspection applications where a high throughput is vital.

For more information about POLKA, please visit: http://s.fhg.de/POLKA