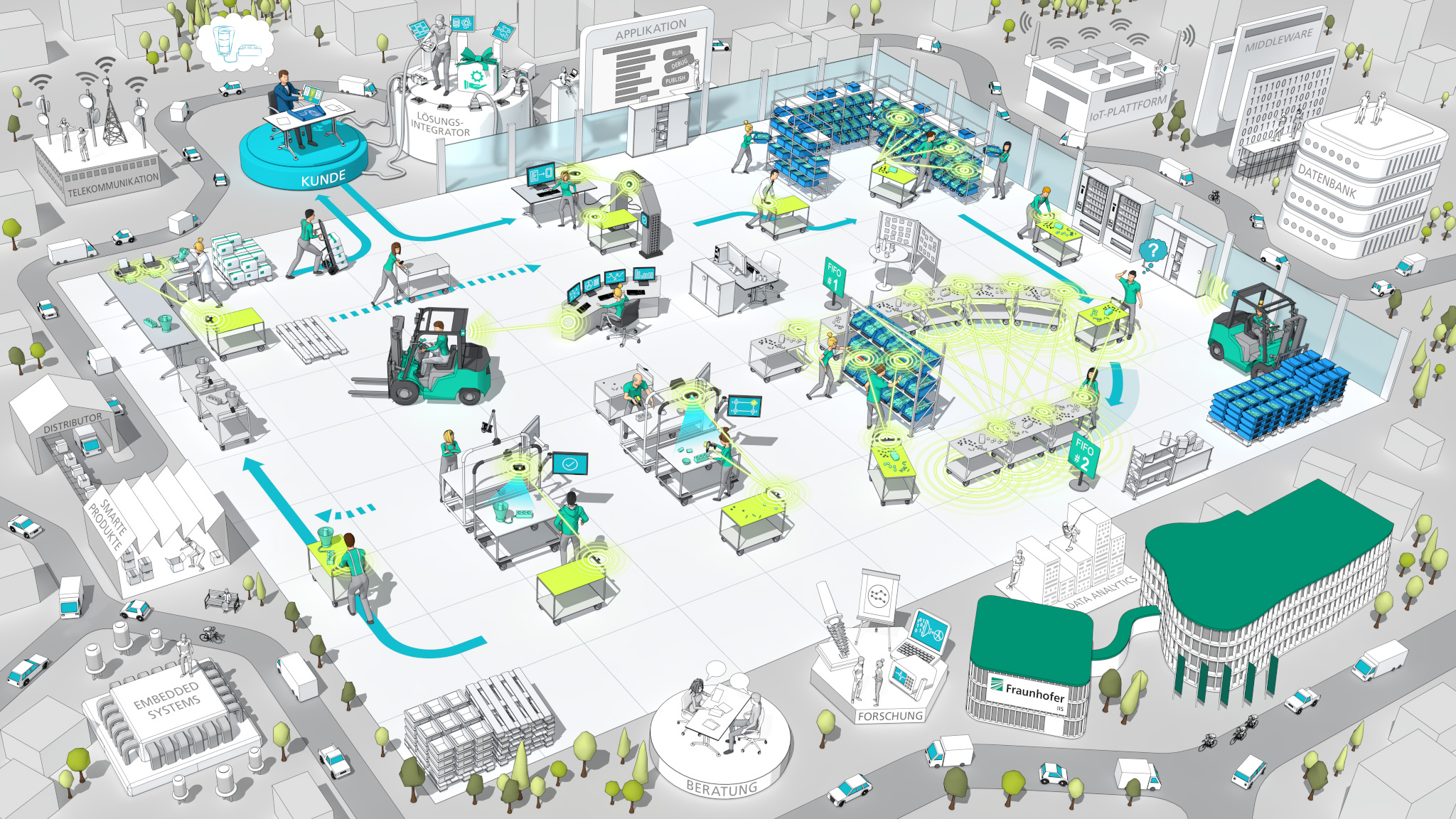

Stephan Oswald develops solutions for Industry 4.0 processes in the Fraunhofer Center for Applied Research on Supply Chain Services SCS at Fraunhofer IIS. The new wireless pick-by-light technology improves manual picking by allowing orders to be put together much more flexibly, which takes some of the complexity out of the picking process. But how exactly does this technology increase flexibility and reduce error rates? Find out more in the interview.

Complex manual picking made flexible and error-free – with wireless pick-by-light technology

October 10, 2021

How warehouses and people can communicate flexibly and wirelessly

Pick-by-light technology has been supporting order picking in industry settings. How does picking work?

Stephan Oswald: In production and in warehouses, pick lists are made up of various items – screws, plastic components, tools and the like. A bright flashing LED light on the compartment signals to the picker which compartment is the correct one before they grab the item from the storage box. This cuts down on long search times.

You have further improved the system with wireless pick-by-light technology. What benefit does this offer companies?

With wireless pick-by-light technology, the display is no longer hardwired to the compartment; wireless connectivity via radio makes companies even more flexible. We attach radio-networked display modules to the box as a mobile part. This means that the storage container can be quickly moved to another shelf or its contents transferred to a larger container – always together with the mobile display. But doing so doesn’t change anything for the pickers: they will still be guided to the right place with pinpoint accuracy even when items have changed location.

What are the parts of the system?

The system consists of displays for the compartments, with LED lights to grab the pickers’ attention, and an e-paper display that shows the most important product information. These are controlled via a gateway. Whenever a picker takes parts out of the compartment, they acknowledge this by pressing a button on the display and the message is sent wirelessly to the software that’s used to manage the warehouse.

Is anyone already selling the wireless pick-by-light technology you developed?

The company Ast-X GmbH launched the system on the market under the name TRILUM.

Every company is different, so how do you create custom solutions?

We try to make the process for Industry 4.0 as efficient and as uncomplicated as possible for the customer. To do this, we first perform system testing at Fraunhofer IIS and later conduct field testing at the customer’s site. The system can then be installed and put into operation directly at the company, with simple app-supported connection of the article and display module.

About Stephan Oswald

In 2018, Stephan Oswald joined the Fraunhofer Center for Applied Research on Supply Chain Services SCS at Fraunhofer IIS, where he researches solutions for digitalizing logistics and industrial processes. As a research fellow, he develops concepts consisting of hardware and software components based on networking technologies, particularly via radio, for Industry 4.0 processes.