The “Industry 4.0 for SMEs” series in the Fraunhofer IIS magazine

As we transition toward Industry 4.0, small and medium-sized enterprises (SMEs) in particular often lack the expertise required to assess and harness the potential that digitalization holds for their operations. The hurdle for the introduction of new technological solutions seems to be particularly high in this group – although even a modest investment can achieve a lot when applied in the right places.

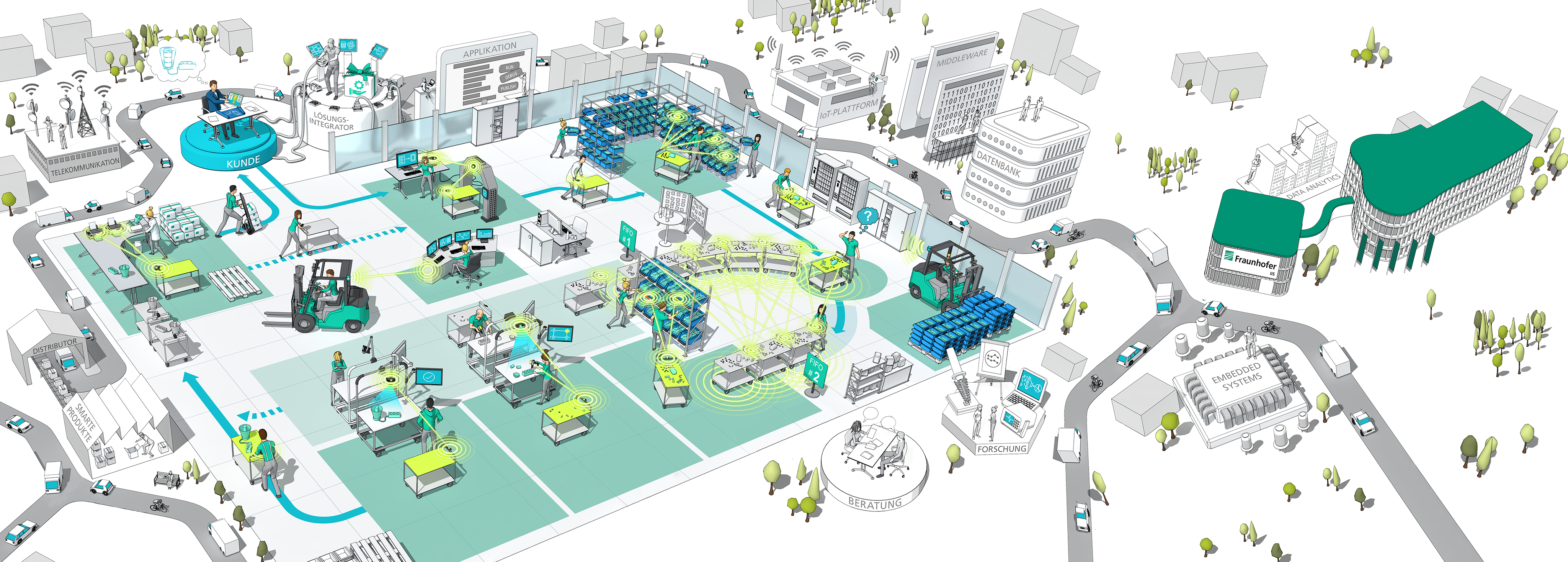

That was precisely the remit and the aim for our Technologies and solutions for digital value creation research project: to develop practical applications in the production and logistics environment that can provide straightforward support for SMEs and their employees on the road to Industry 4.0. To this end, Fraunhofer IIS adopted a holistic approach: we combined the economics and analytics expertise of our Center for Applied Research on Supply Chain Services SCS with the technological know-how of our Positioning and Networks business unit.

In our ten-part magazine series, we present the results of this five-year research project. We will introduce to you our easy-to-integrate, flexible and easily expandable technological solutions. And you will learn about the accompanying concepts from an organizational, management and technological perspective that SMEs need to consider to make their digital transformation a success.

We hope that reading this series provides you with valuable insights. If you have any further questions or need advice, please don’t hesitate to contact us.