We develop systems using X-ray technology (2D and computed tomography) for production monitoring and production control that detect deviations from optimum production processes at an early stage in order to minimize production rejects.

Production monitoring goes beyond nondestructive material testing (NDT), which does no more than judge the quality of a workpiece, and production monitoring also has the aim of intervening in the production process to correct it if certain thresholds aren’t met.

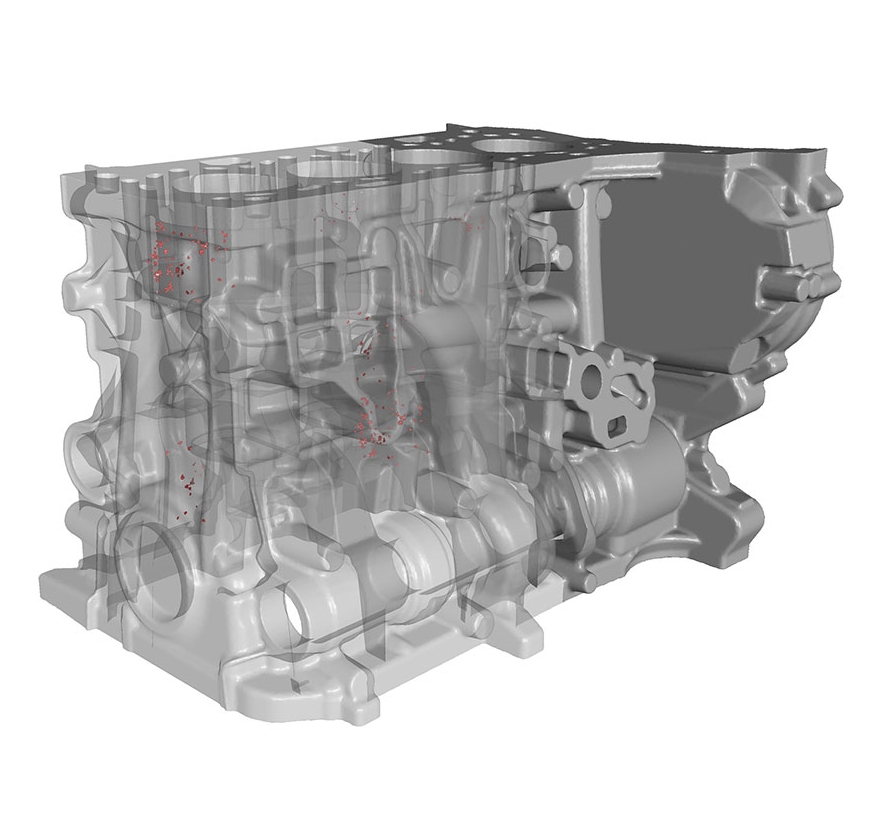

Casting defects such as cavities or pores are not only detected, but also accurately located and analyzed. This permits further processing of components with abnormalities, which would previously have been treated as rejects due to a lack of information, as long as those abnormalities are in a non-critical area or if the region is later processed mechanically. Computed tomography (CT) is a particularly suitable tool for this, as it produces an accurate 3D image of the components. Moreover, the metadata obtained feeds directly into the manufacturing process. This intelligent data feedback means production parameters such as pressure or temperature can be set in such a way as to prevent critical errors from occurring in the first place.