How to transfer knowledge about data analytics and AI to industry

Supply Chain Services / September 26, 2023

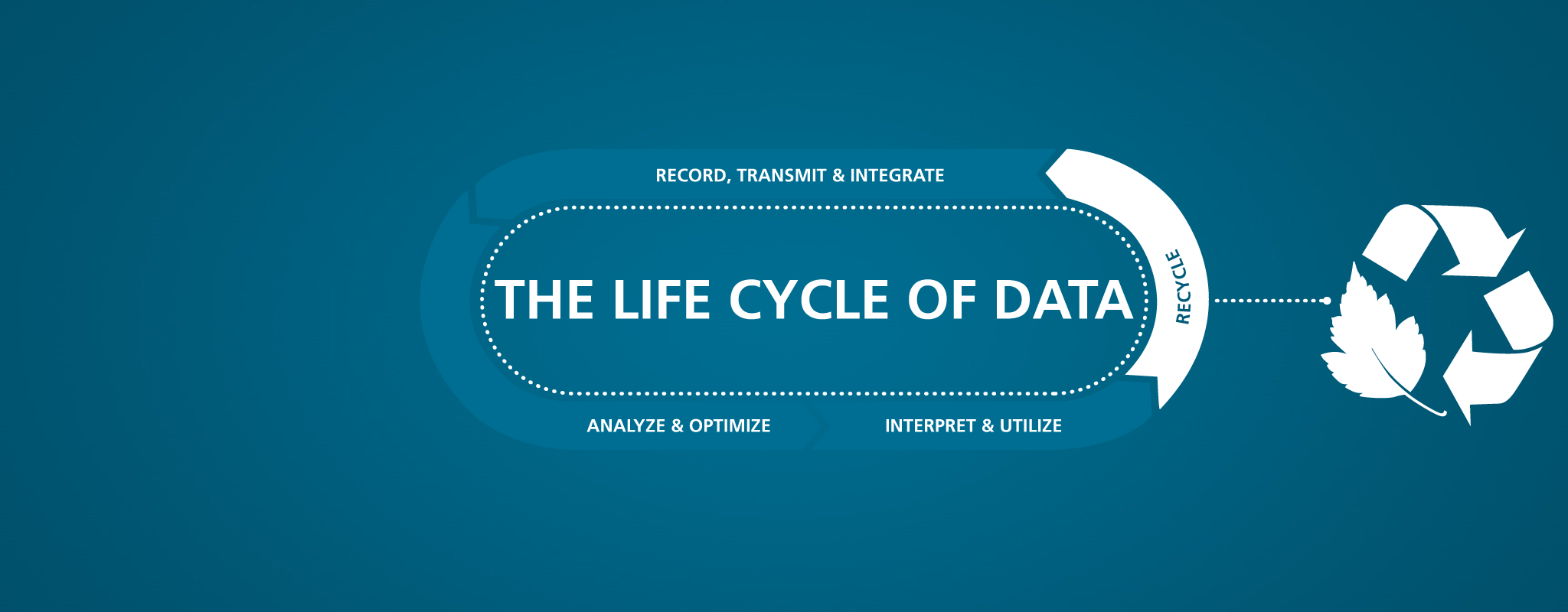

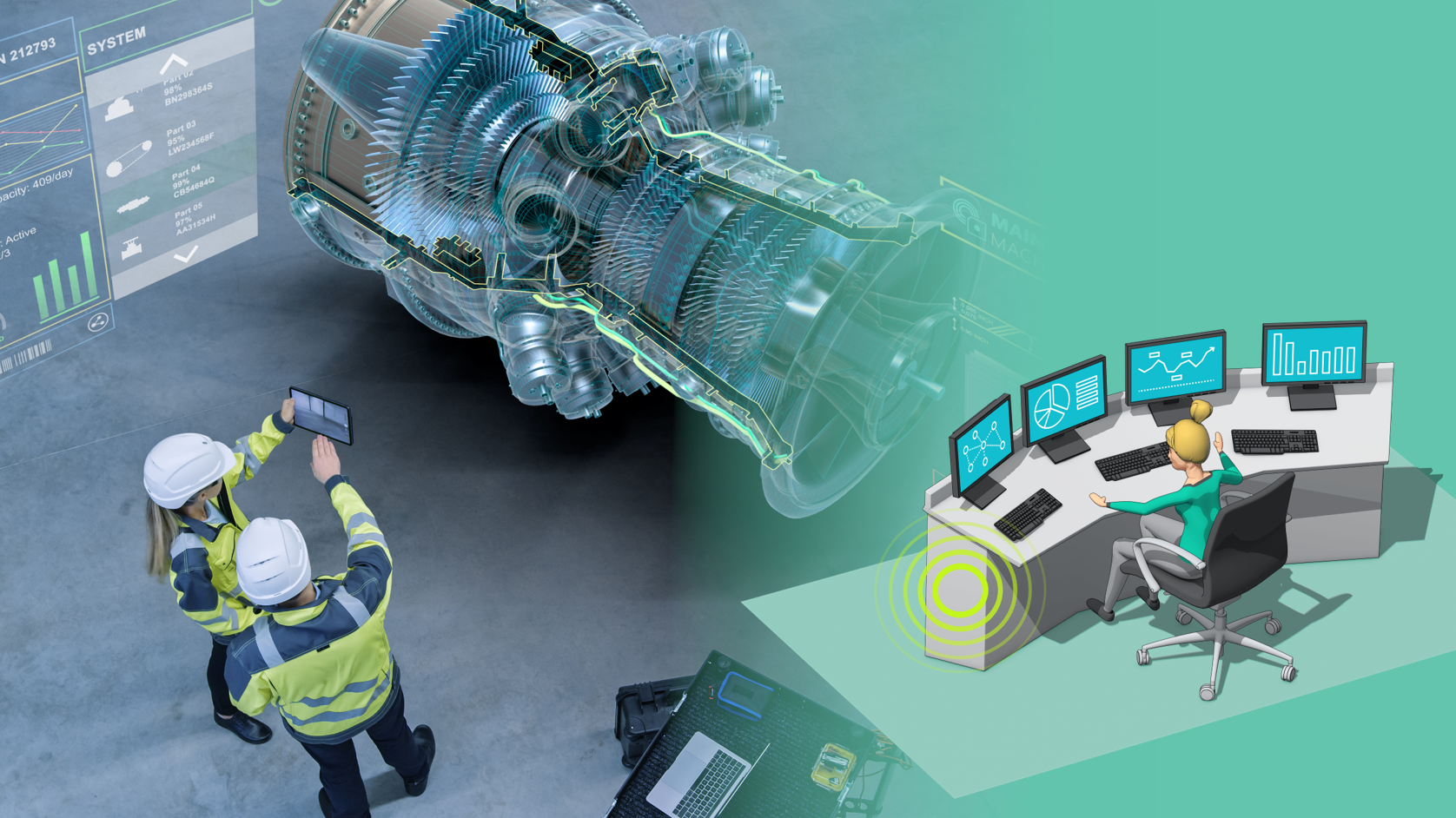

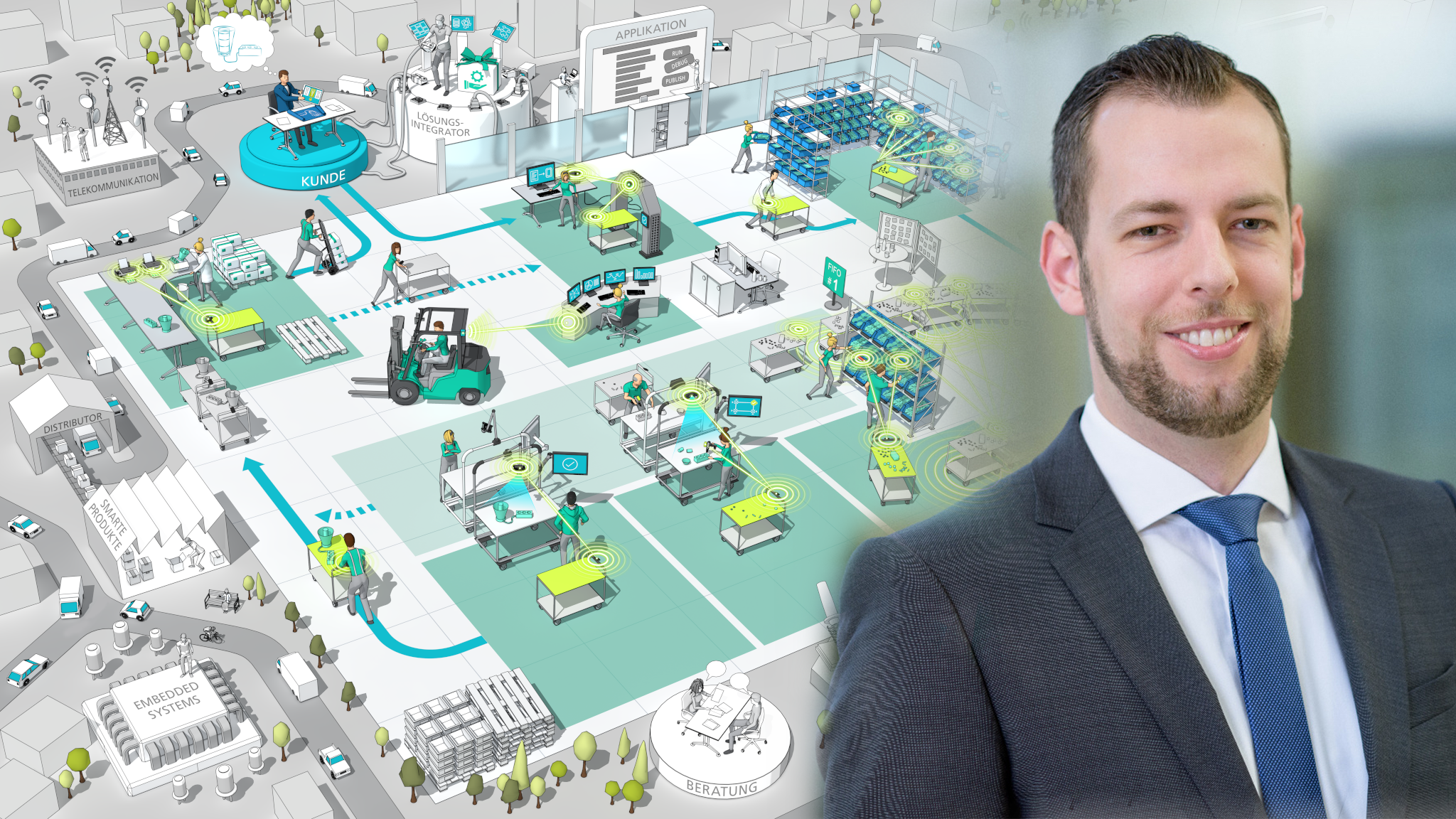

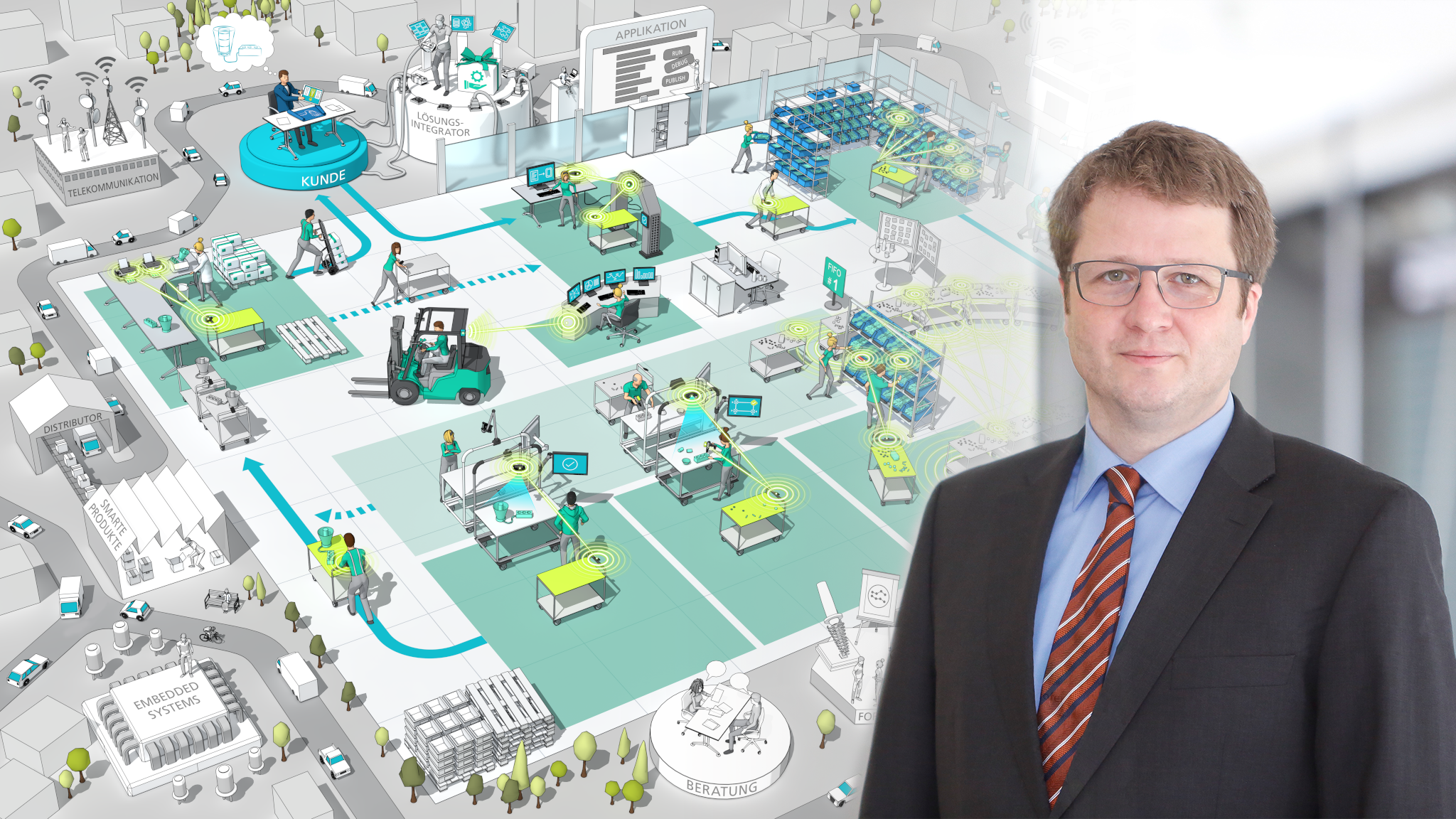

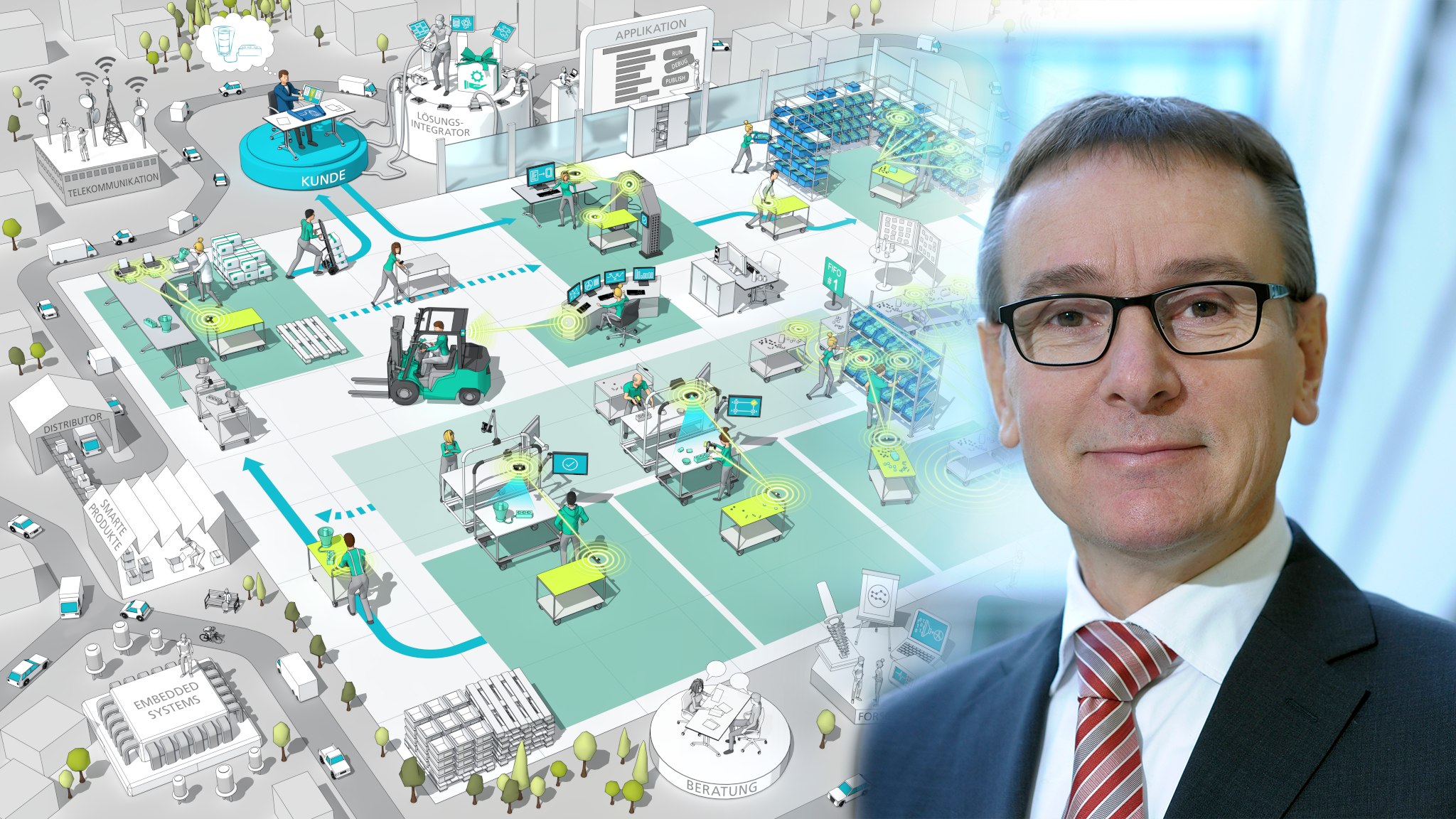

Over the past five years, the ADA Lovelace Center has built up an international network that connects science and industry. These connections make it possible for research into AI, machine learning, and optimization to find its way into practice. Visitors to the Conference on Optimization and Machine Learning in Industry, held in Nuremberg in March 2023, noted that the competence center for AI is and will remain an important hub for companies that want to ready themselves for future international competition by means of digitalization.