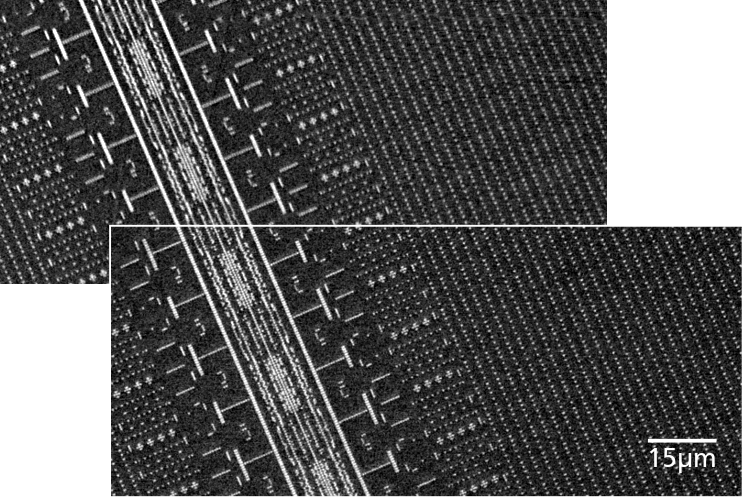

3D-computed tomography for the visualization of smallest structures

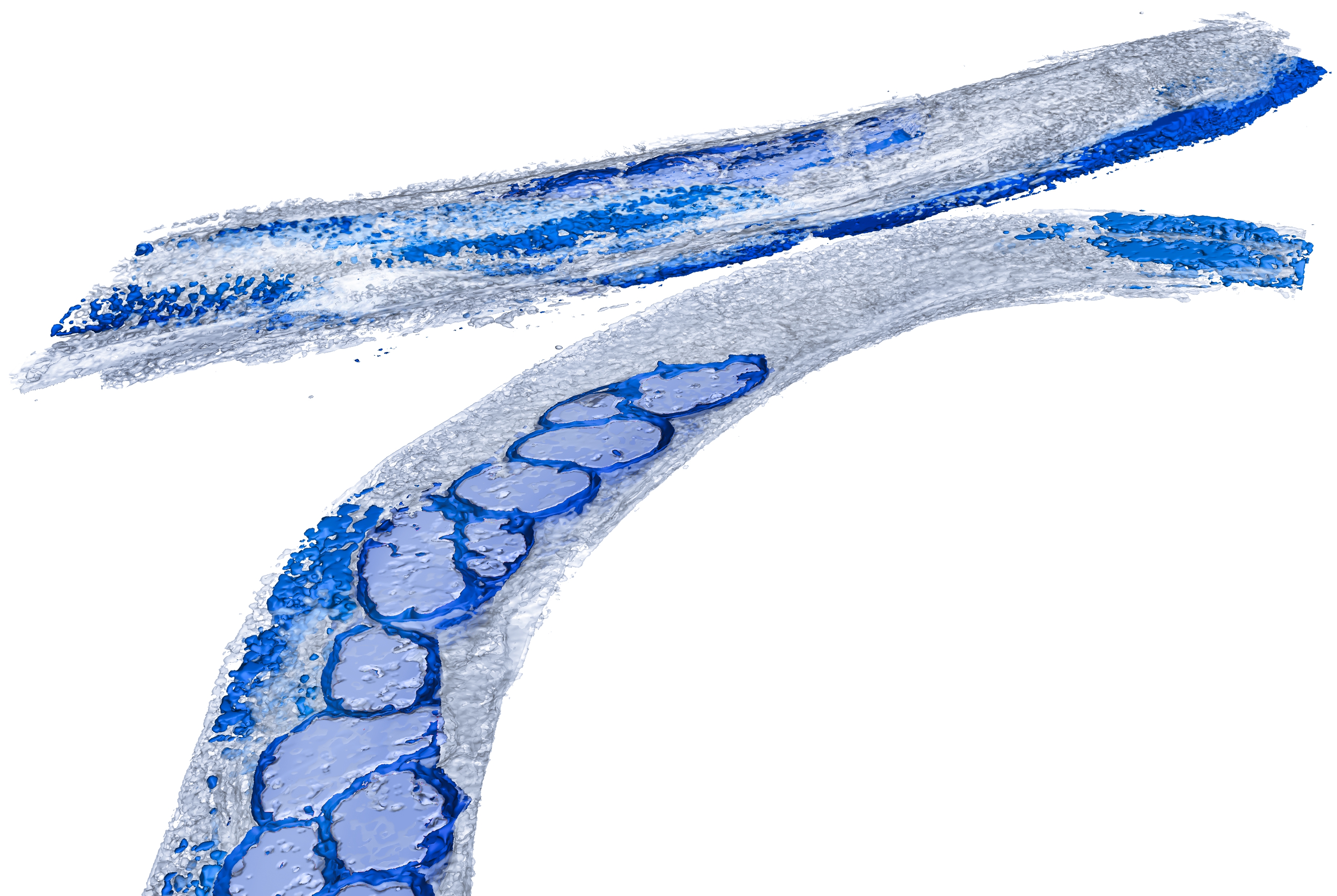

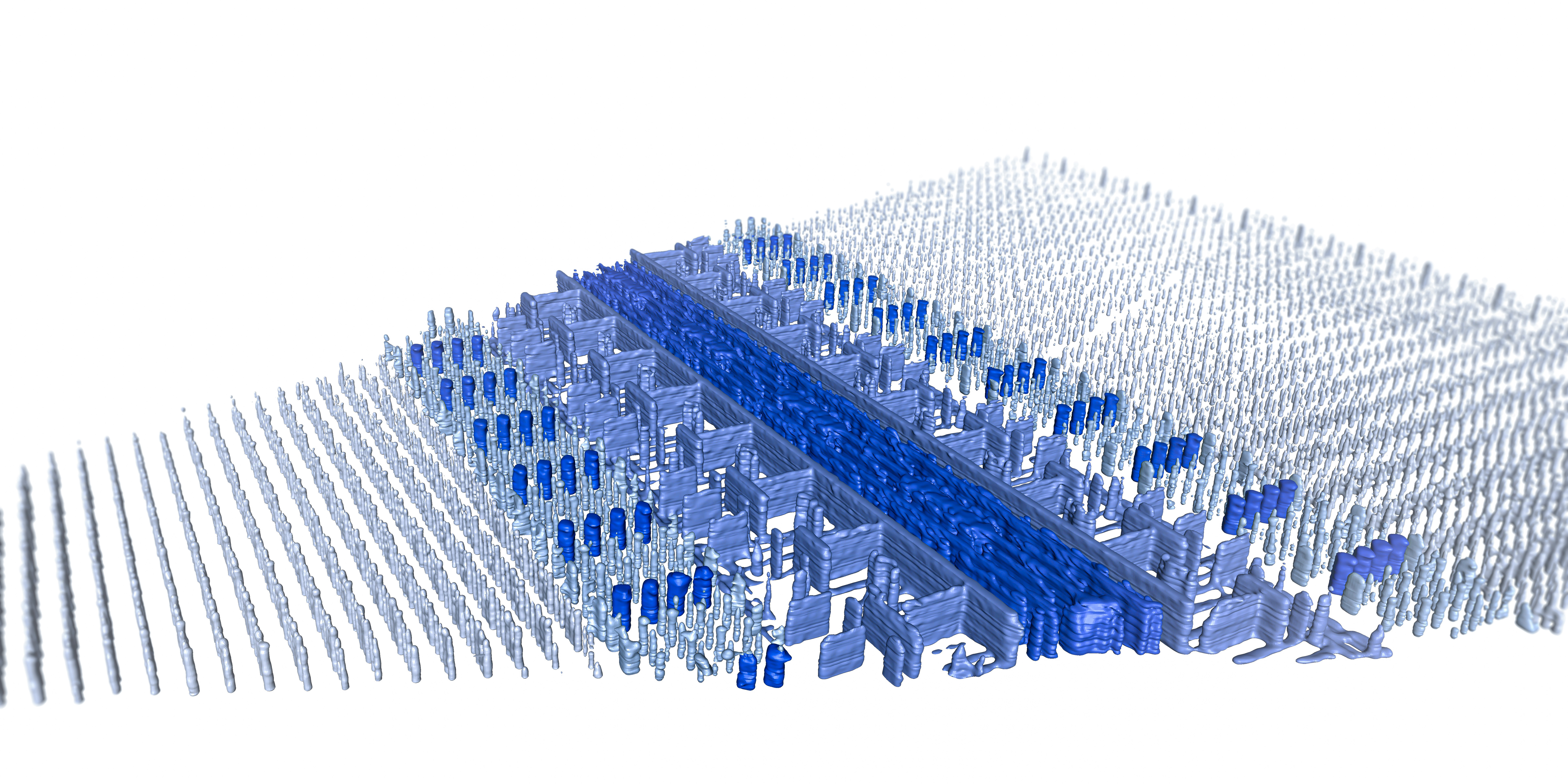

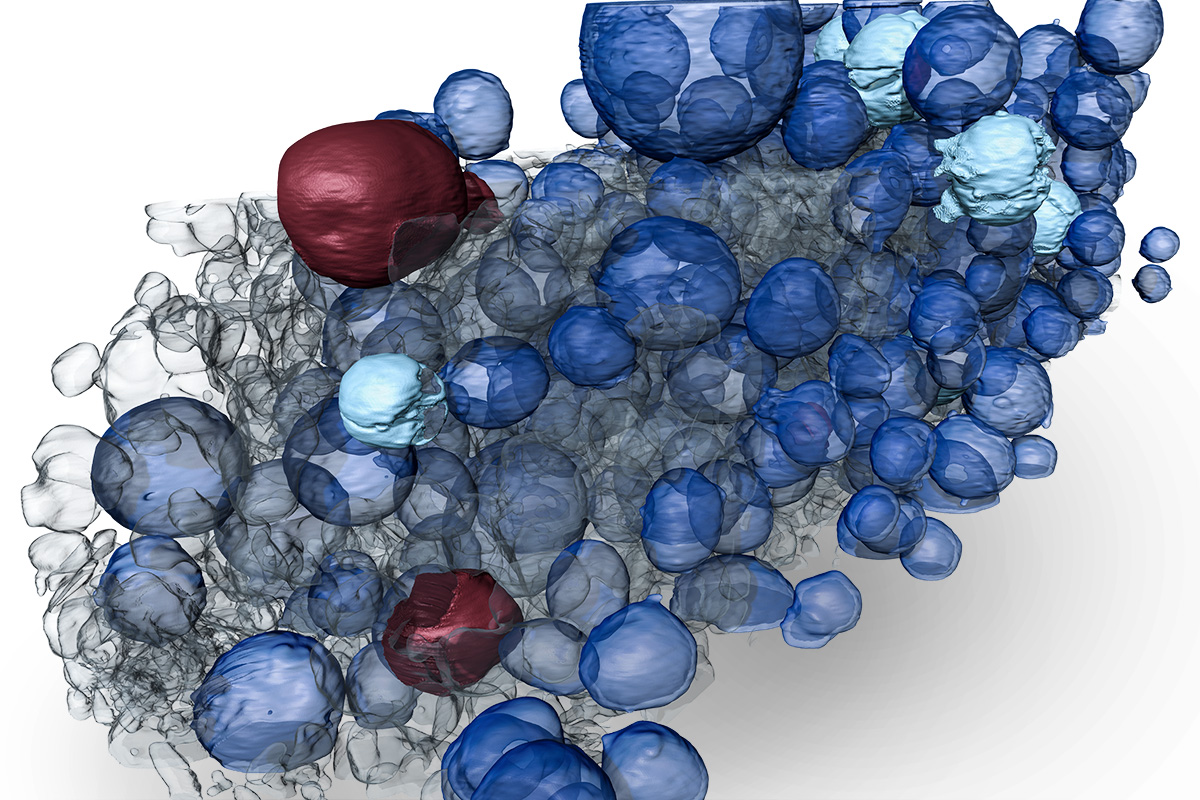

The functional features of novel material systems are often based on their complex inner structures, which are not accessible by established non-destructive analysis methods. The fabrication of microelectronics and micromechanics becomes more and more complex, packed and 3D. After decades of successful miniaturization, industry now produces structures too small for established process control, hindering further improvements. Moreover, biological investigations would require more detailed 3D information of hidden inner structures in order to understand the morphology of various organisms, but such samples often provide too low material contrast.

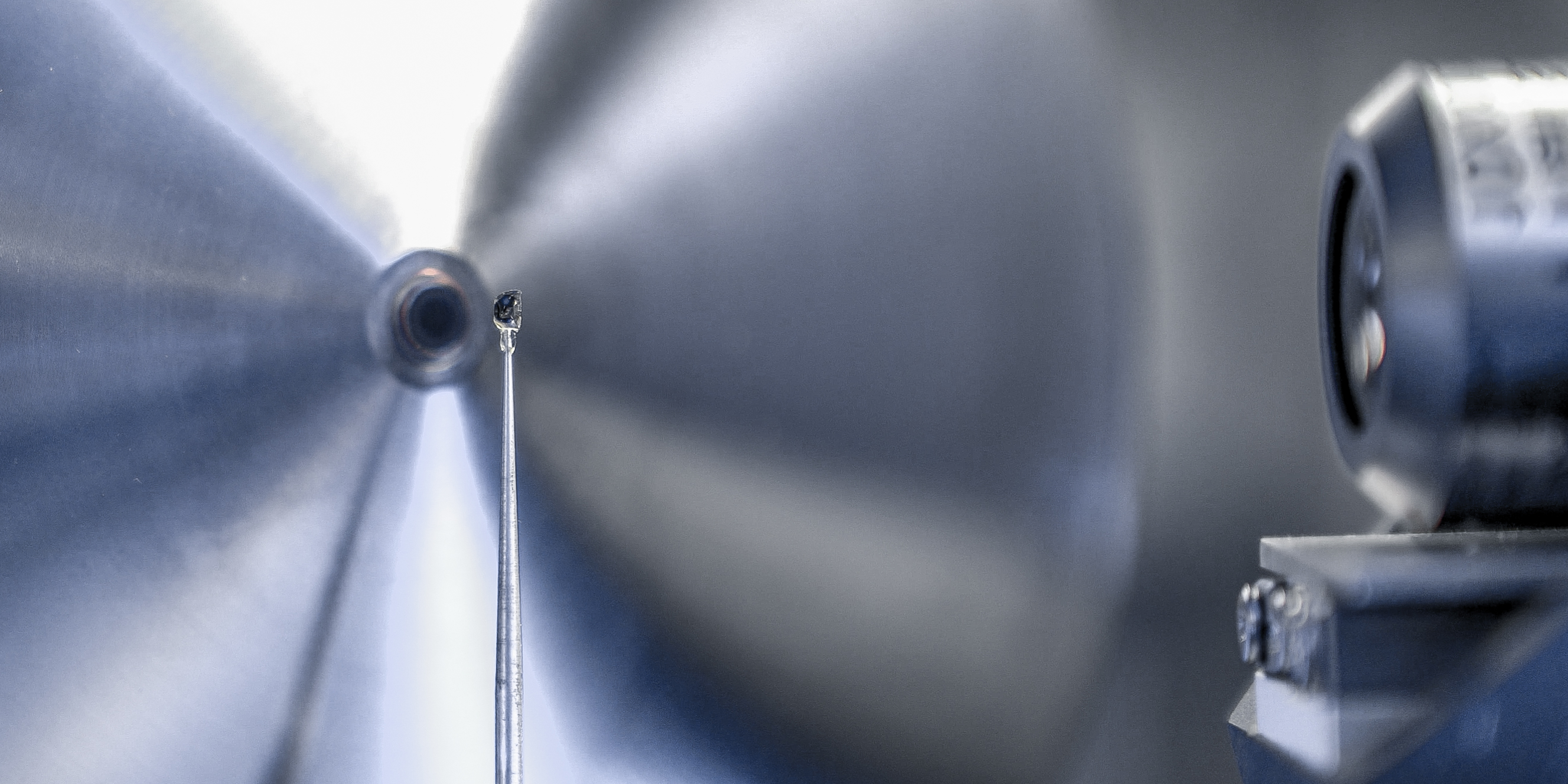

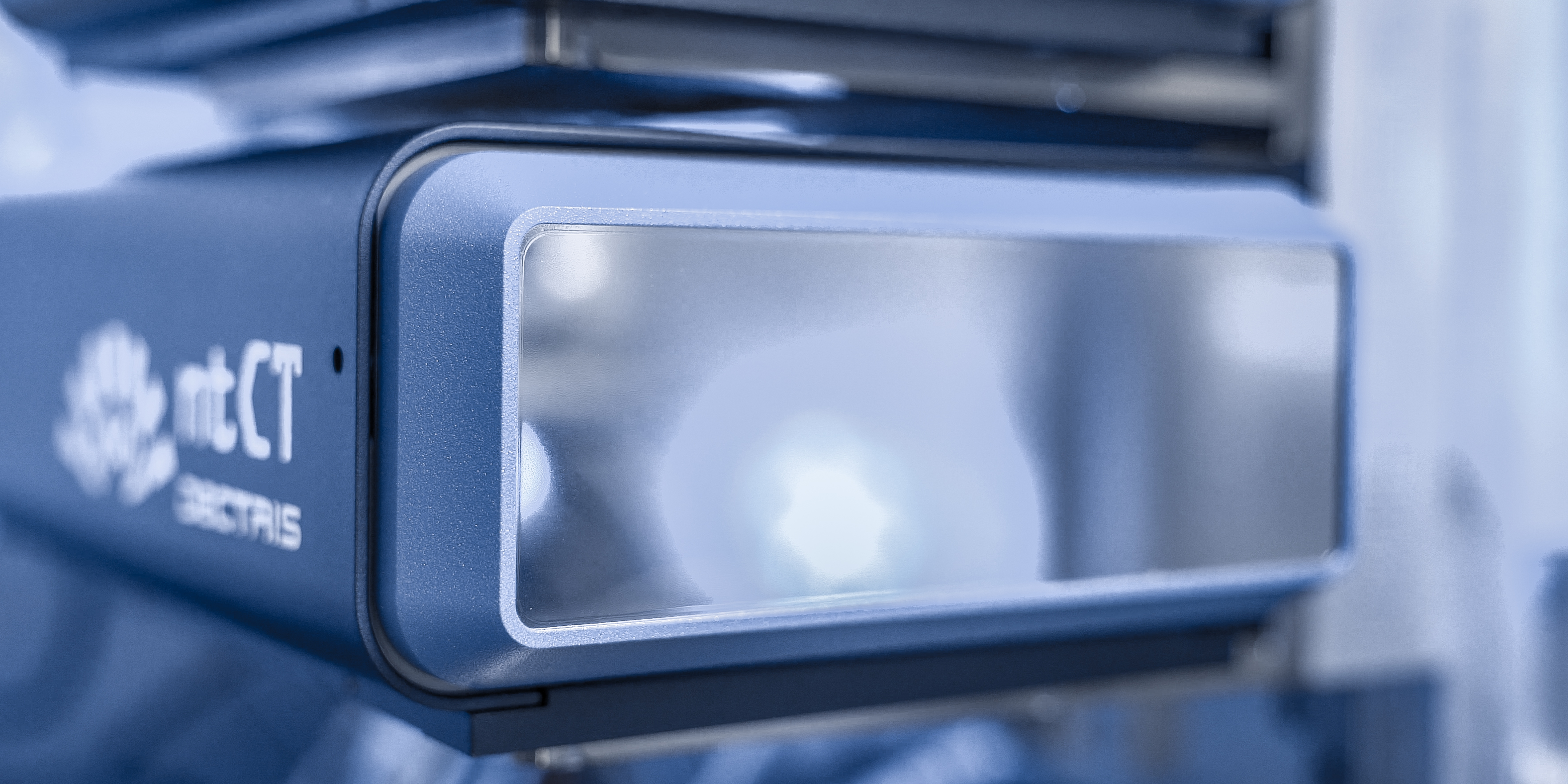

The ntCT provides a unique solution for all these high-resolution measurements far ahead of established industrial micro CT scanners by applying the latest developments from x-ray research.