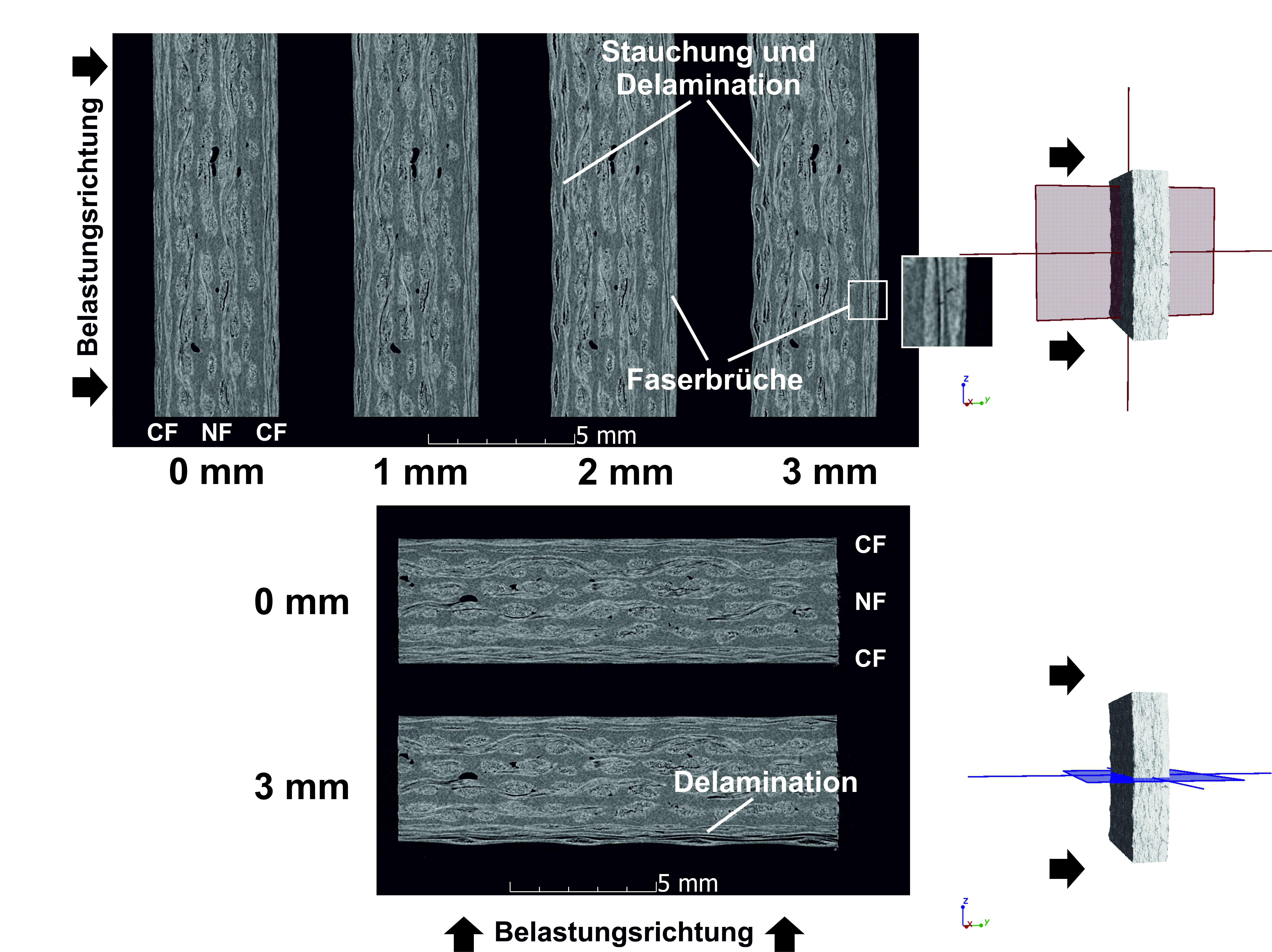

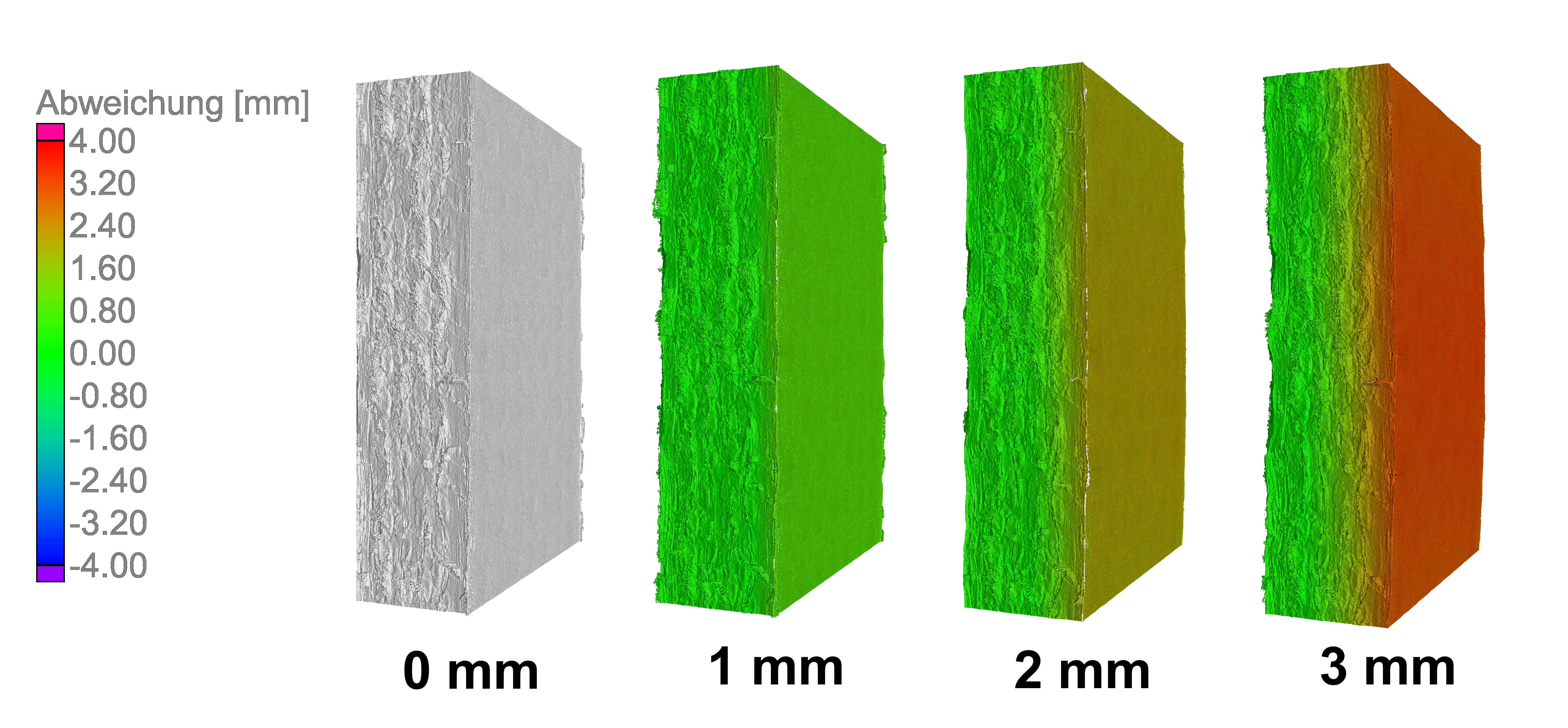

Classical 2D and 3D computed tomography provides information about the structures hidden inside the test objects in a static state. However, if the test object is subject to a dynamic change, such as movement due to physical processes, it is necessary to measure all states that are relevant for acquiring knowledge. The portable in-situ stages of the Fraunhofer Application Center CTMT facilitate CT measurements on tensile specimens or components while forces are simultaneously applied.

In-situ computed tomography

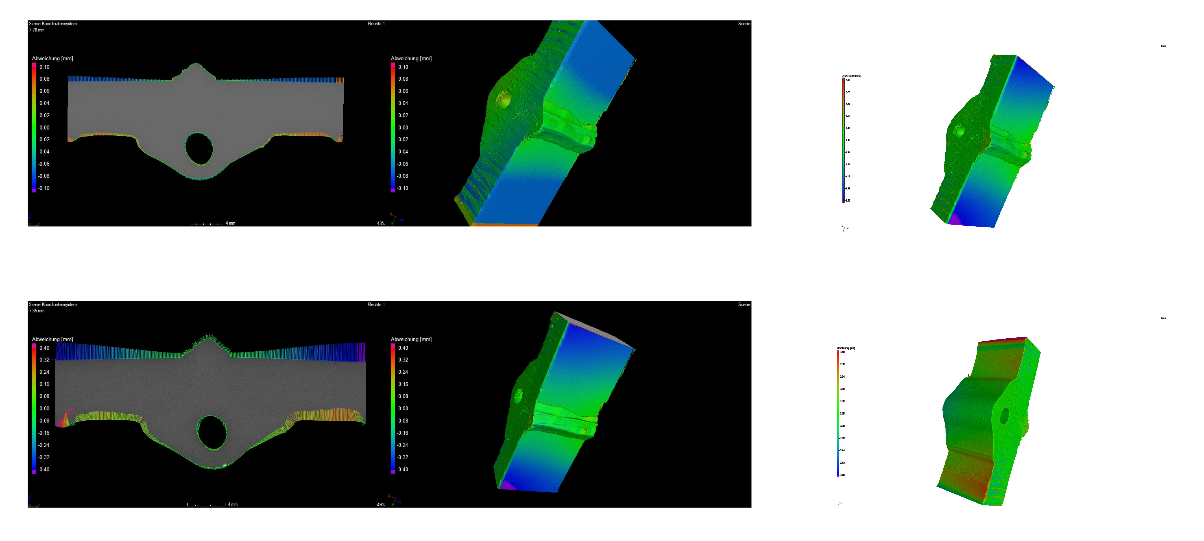

With dimensional measurement and material testing using non-destructive in-situ computed tomography, samples and test objects of all kinds can be examined for deformation and, for example, cracking under the application of force.

The in-situ stages can be integrated into conventional computed tomography systems regardless of the manufacturer. Control is achieved via external programs, but this can also be integrated into the user’s own programs via API.

The Fraunhofer CTMT has already built various systems for tensile/compressive loads, for example, or bending moments:

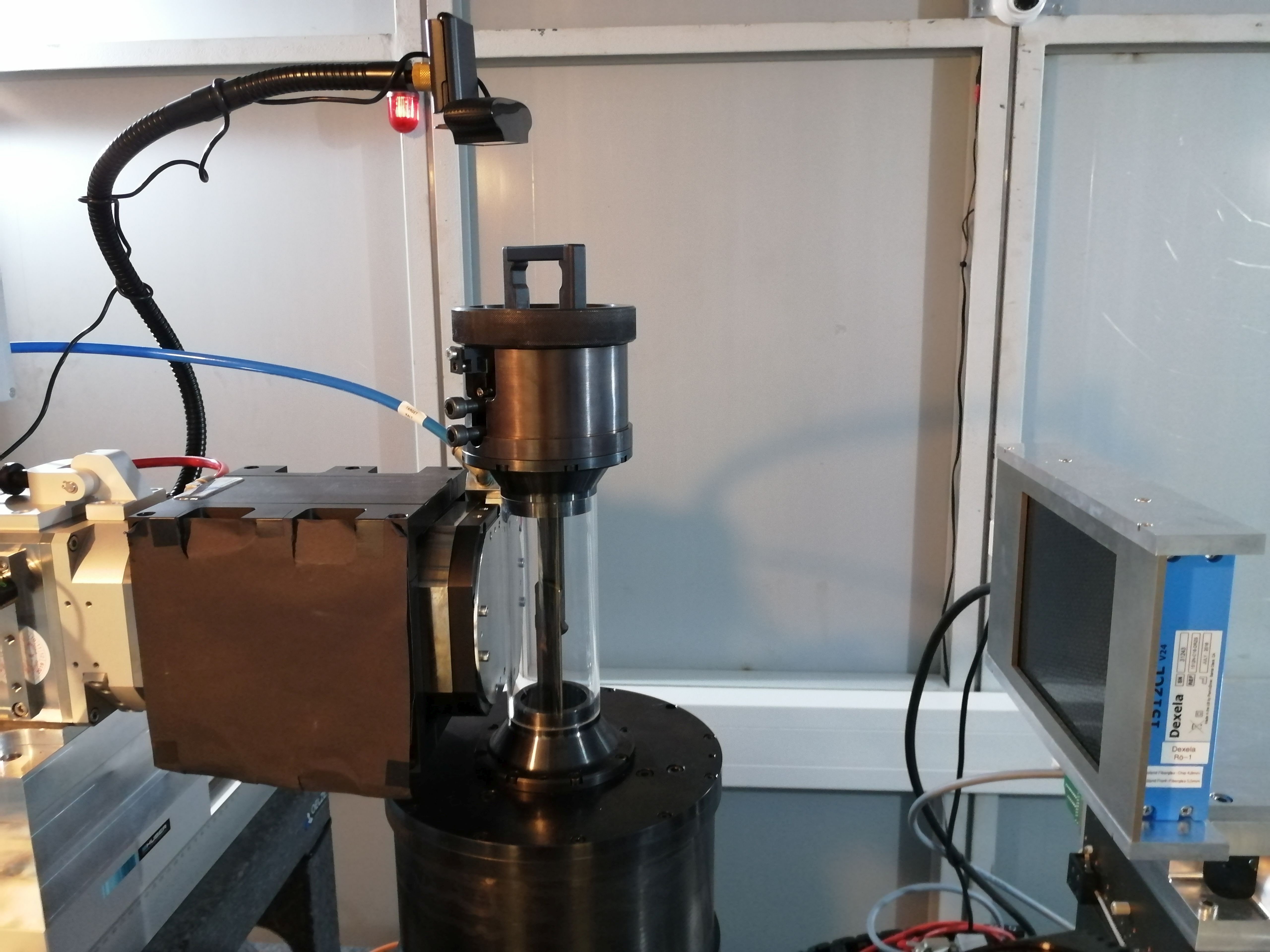

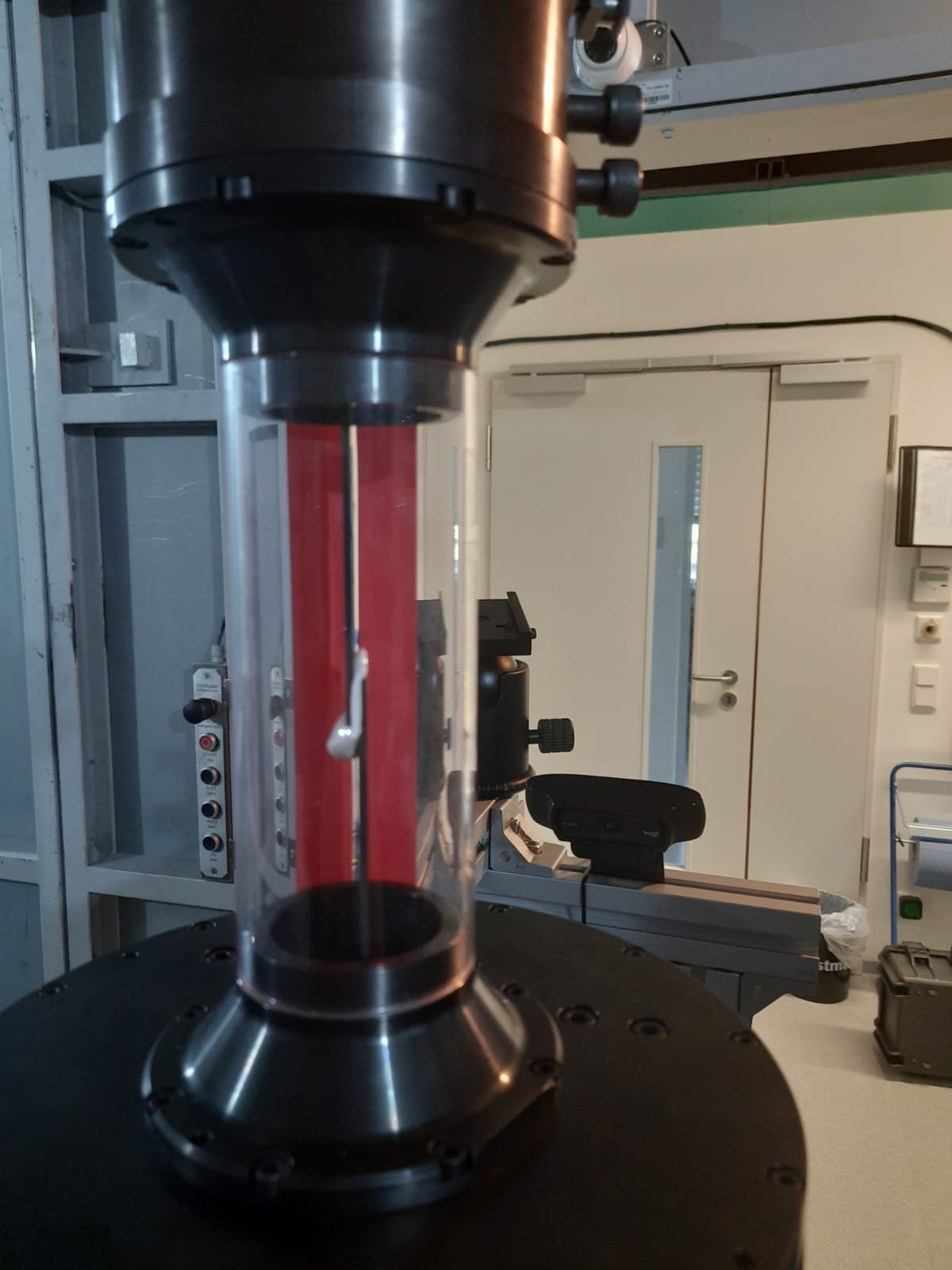

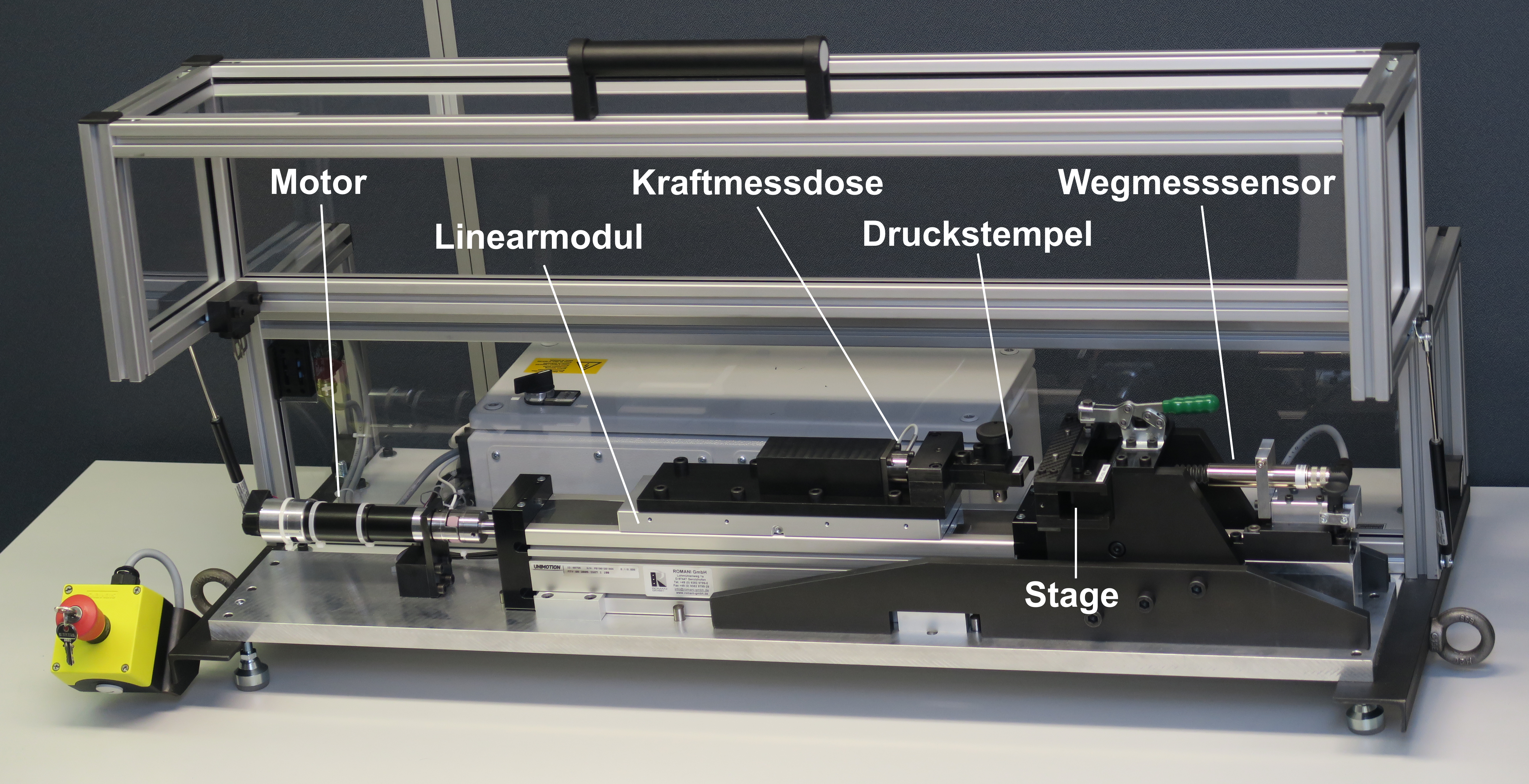

In-situ stage for higher loads

In-situ stage for higher loads

This fixture is designed to apply a defined tensile or compressive force to objects of any shape. Due to the dimensions, larger objects with a size of approx. 150 x 150 mm² (ØxH) can also be examined with a max. force of 15 kN.

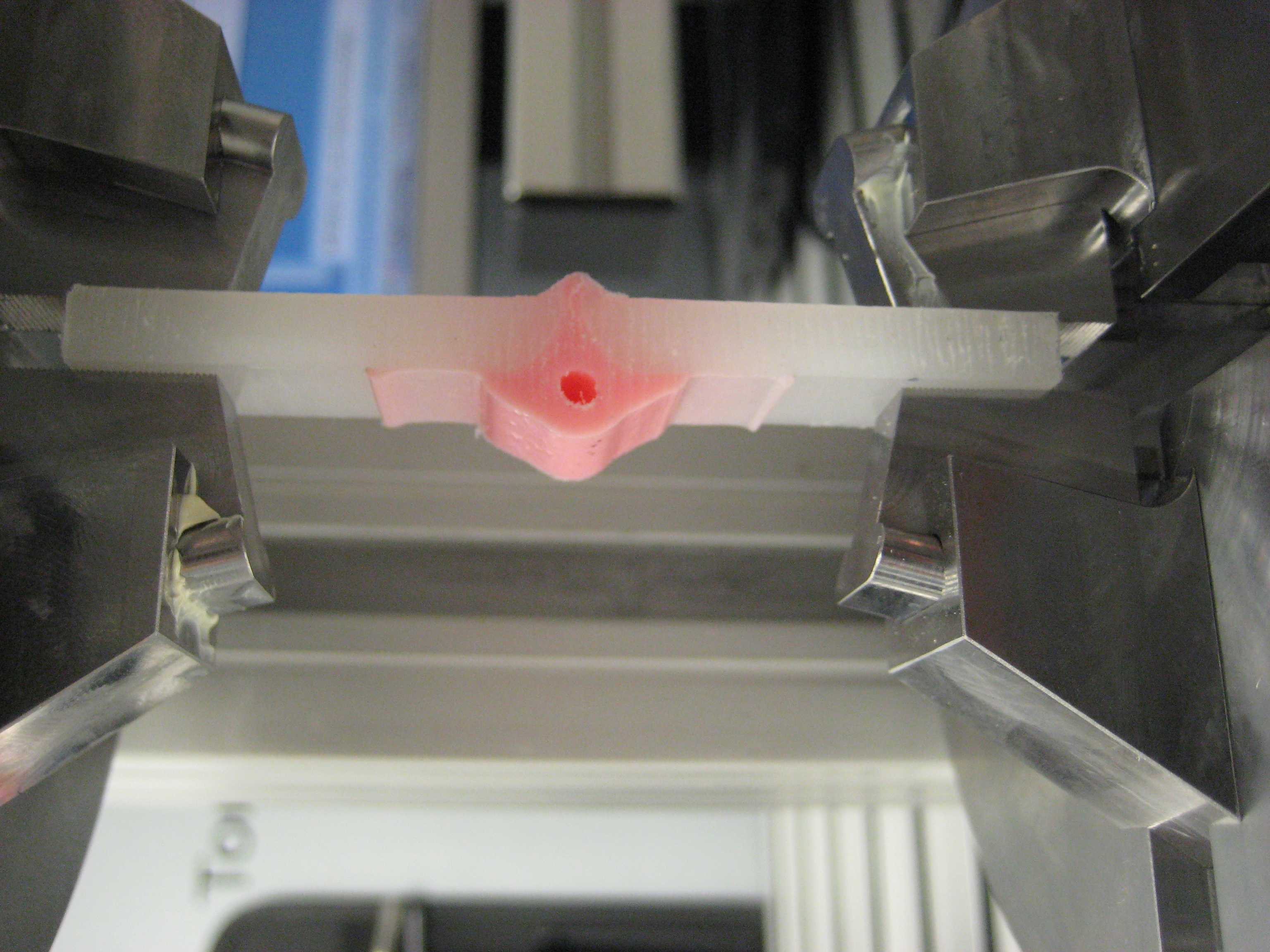

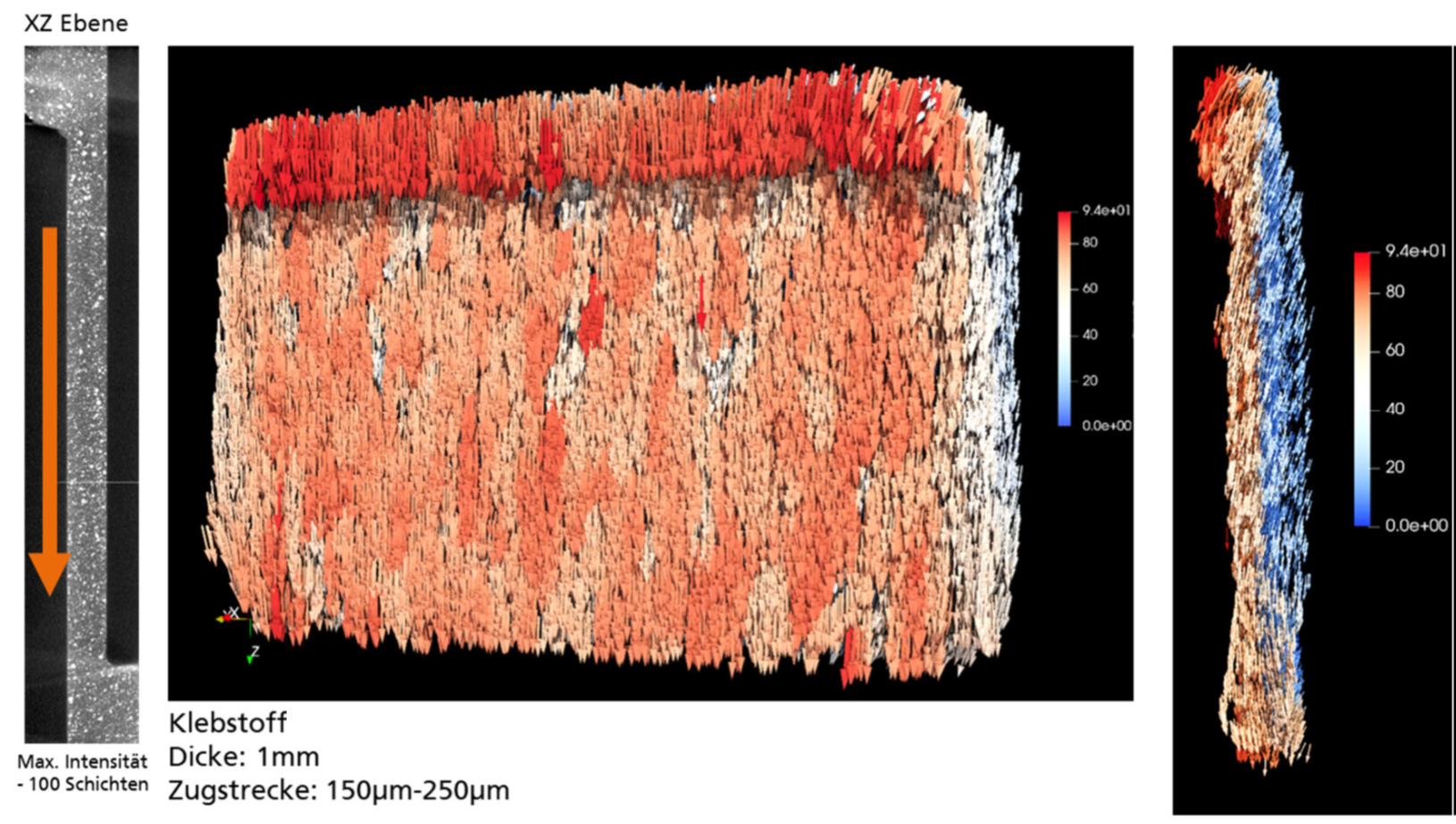

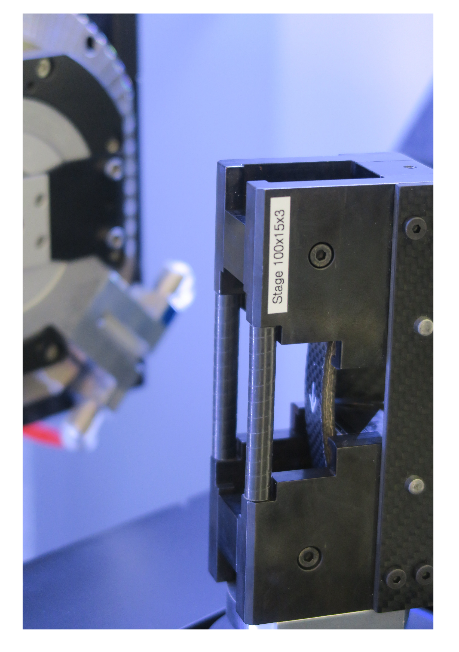

In-situ stage for smaller loads and high resolutions

In-situ stage for smaller loads and high resolutions

This stage is also used to test smaller samples, such as standardized tensile specimens (cf. DIN EN 1465, DIN EN ISO 527), cables, films, etc. Due to the small dimensions of the sample chamber, voxel resolutions of <10 µm (depending on the CT setup) can be achieved. The force can be continuously increased up to 1.5 kN during the tests. Path-controlled tests with a step size of approx. 1 µm are also possible.

In-situ stage for bending tests

In-situ stage for bending tests

Another form of load is made possible by this in-situ stage. Here, flat test specimens can be subjected to what is known as a four-point bending load (cf. DIN EN ISO 14125). This type of load test is particularly interesting for all types of fiber-reinforced plastics, as it can be used to make delaminations visible, among other things. With a maximum force of 5 KN and simultaneous measurement of the deformation, a large number of different samples can be examined.