"ntCT" nano CT system: Industrial nano computed tomography now commercially available

Würzburg/Hannover: The Development Center X-ray Technology EZRT at the Fraunhofer Institute for Integrated Circuits IIS has further developed the "ntCT" nano CT system in collaboration with partners. This improved system is now commercially available via the system integrator, ProCon X-Ray. "ntCT" is suitable for the microscopically fine investigation of sample objects with a resolution of up to 150 nanometers. By integrating the latest generation of X-ray tubes, the system now supplies outstanding resolution while also greatly reducing the measuring time.

The main functional features of novel material systems are often based on their complex internal structures, which are not accessible by established nondestructive analysis methods. Moreover, the manufacture of microelectronics and micromechanics is becoming increasingly more complex and more compact, not to mention three-dimensional. After decades of successful miniaturization, the industry today produces structures that are often too fine to be investigated using established systems.

Next-generation X-ray tubes

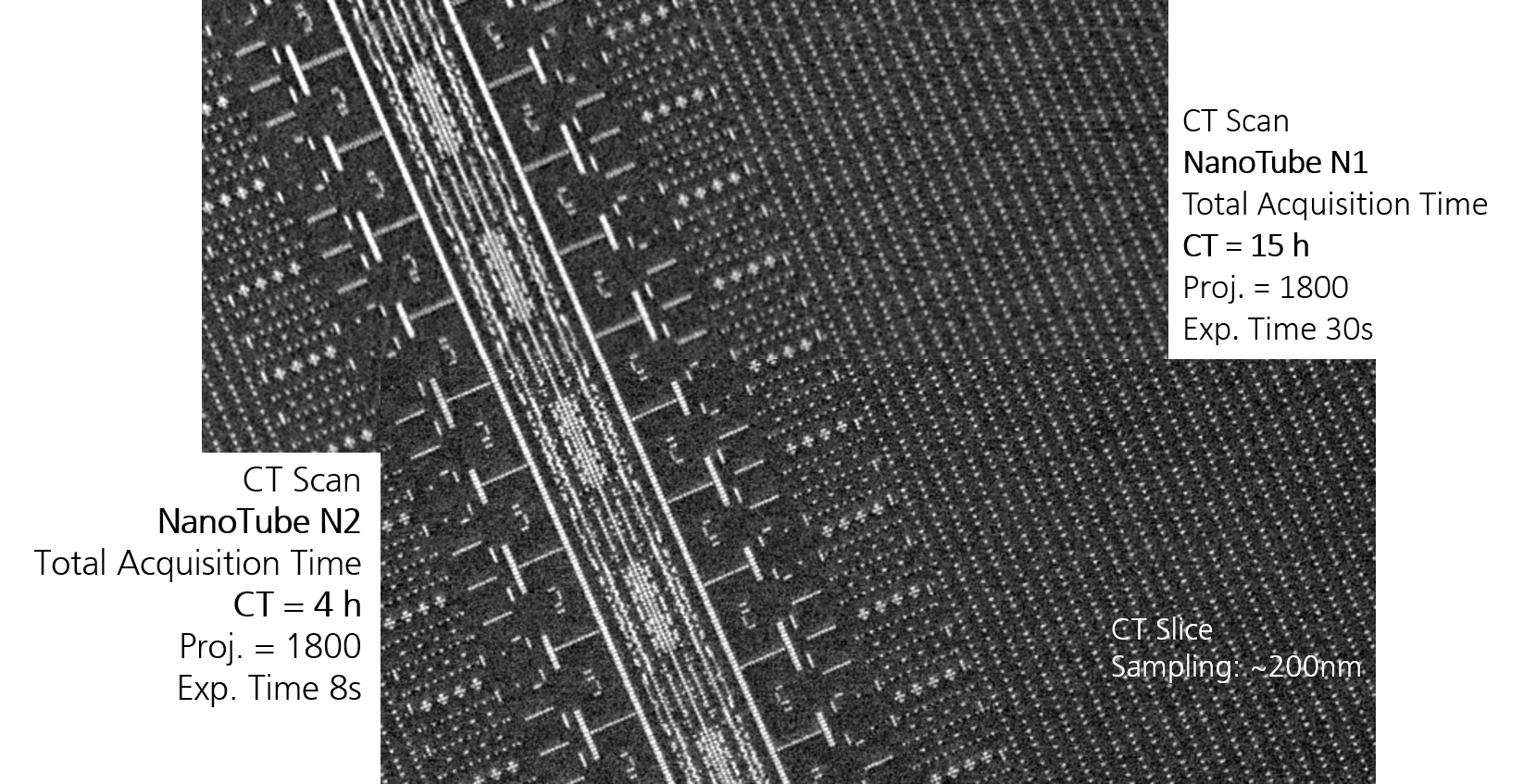

In 2018, Fraunhofer EZRT unveiled the first generation of the "ntCT", which was able to handle such special requirements. In collaboration with the Swedish company Excillum AB, the X-ray source, which is one of the core components of the system, has been further improved. The result is a considerable increase in performance, such that measuring times have been substantially shortened while offering the same outstanding resolution. Consequently, the system can achieve measuring times of just a few hours for a complete CT scan with sampling down to 50 nanometers and a resolution better than 200 nanometers, now rendering it ideal for industrial requirements as well.

This makes nanoscale tomography suitable for integration into manufacturing environments. In addition to the system’s highly automated operation for most applications, users can access all setting parameters and raw data in an advanced operating mode. For objects such as microelectronics, which require the use of higher X-ray energy, the system can be delivered in a 110-kilovolt version. "The 'ntCT' system offers a wide variety of possible applications for practically all sectors that need nondestructive 3D analysis with maximum resolution. The system is more than just hardware, it’s a complete analytic environment, which accompanies users from the insertion of samples through to the reconstructed data," says Dr. Christian Fella, Head of the "NanoCT Systems Group" at the Würzburg location of the Fraunhofer Development Center for X-ray Technology EZRT.

Upgraded system now commercially available

The new version of "ntCT" is now commercially available as part of the "ProCon CT-Alpha" product series from the company ProCon X-Ray GmbH. Collaboration between Fraunhofer EZRT as a research-oriented developer and ProCon X-Ray GmbH as a system integrator allows much faster implementation of the latest technological developments into a market-ready product.

In cooperation with