Start of Measurement Series: Fraunhofer IIS and Staatliche Museen zu Berlin Digitize Benin Bronzes Using High Energy Computed Tomography

The digitization of cultural-historical objects cannot replace the original. Nevertheless, there are many reasons to use state-of-the-art technology to create three-dimensional models of historically significant objects. At the Fraunhofer Development Center X-ray Technology EZRT at Fraunhofer IIS, bronze reliefs from West Africa were translated into digital data sets using industrial X-ray computed tomography in collaboration with the Staatliche Museen zu Berlin. The digitization of the first museum pieces demonstrated the feasibility of the project.

The Ethnologisches Museum and the Rathgen-Forschungslabor of the Staatliche Museen in Berlin - Preußischer Kultubesitz are currently creating image-based digital copies and 3D scans of over 500 objects from the historical Kingdom of Benin using photogrammetric methods. Ownership of all of these objects from the Ethnologisches Museum's holdings was transferred from the Prussian Cultural Heritage Foundation to the Federal Republic of Nigeria in August 2022.

At the Fraunhofer Development Center X-ray Technology EZRT at Fraunhofer IIS, some of the objects can now be recorded and studied in other important aspects using state-of-the-art industrial X-ray computed tomography before being successively returned physically to Nigeria. Since 2008, the Fraunhofer-Gesellschaft and the Prussian Cultural Heritage Foundation have been working together in the Cultural Heritage Research Alliance, together with the Leibniz Association, the Dresden State Art Collections, and the Saxon State and University Library, to develop new, research-intensive methods in the field of cultural heritage preservation. The joint project on the so-called Benin Bronzes is an example of this successful cooperation. Five selected Benin Bronzes have already been examined in July and August 2021 as part of a pilot study at the Fraunhofer Development Center X-ray Technology. 27 further Bronzes are expected to follow in a subsequent measurement campaign starting in April 2023. The analysis will be carried out with the express consent of Nigeria.

Challenging material composition

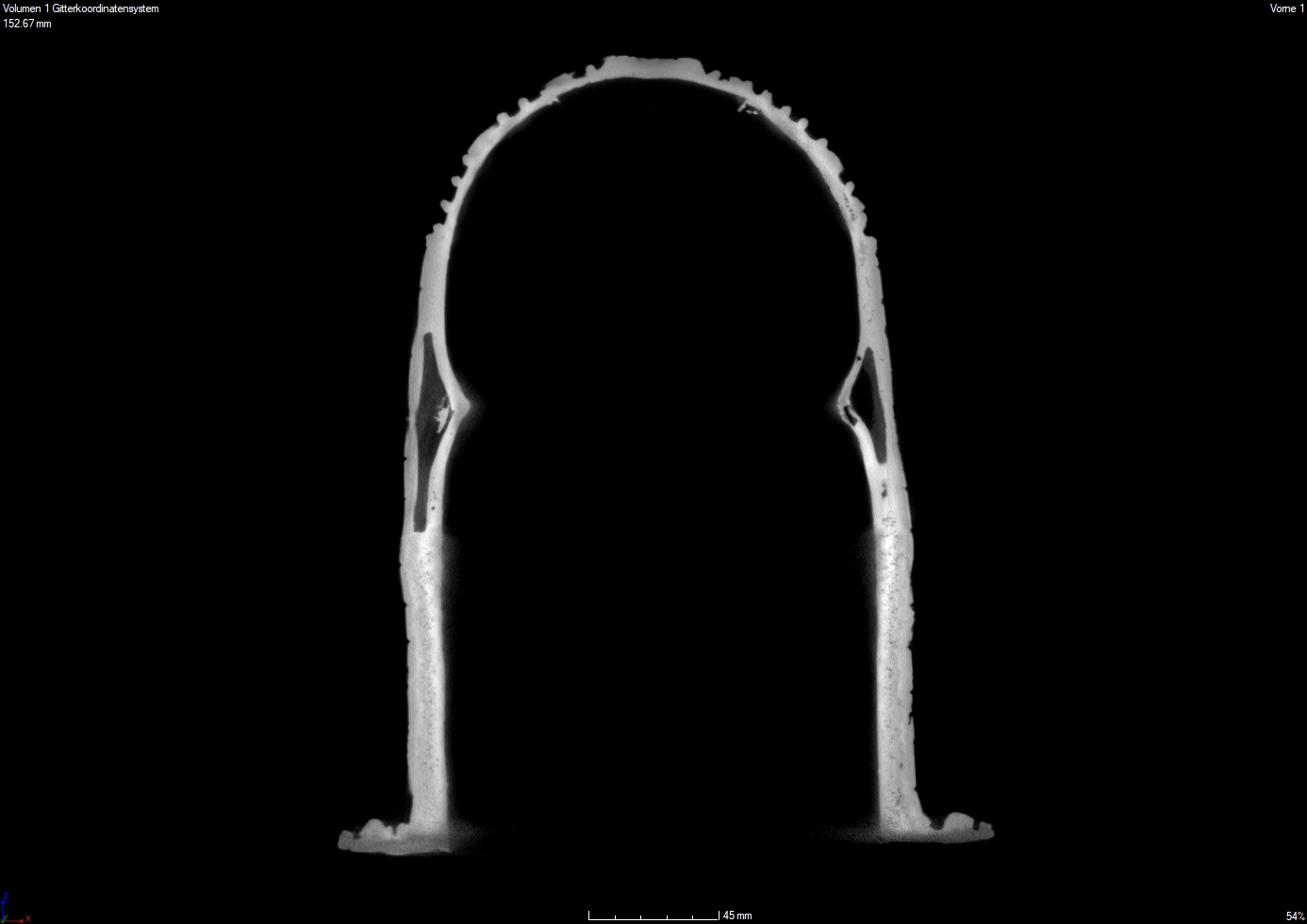

The Benin Bronzes, which are actually made of brass rather than bronze, pose a very special challenge for X-ray technology: The copper alloy from which the sculptures and reliefs are made has a strong absorbing effect on X-rays in the conventional energy range. In addition, the Benin objects are significantly larger and more massive than typical other objects subjected to X-ray inspection, such as aluminum wheels or engine pistons. In order to nevertheless produce very good, noise-free tomography images with high spatial resolution, the researchers at the Development Center X-ray Technology in Fürth use one of the largest CT systems available anywhere in the world.

The high-energy CT system applied generates X-rays with up to nine mega electron volts by means of a linear accelerator in order to X-ray highly absorbent materials. Thanks to complex mechanical engineering that allows the system to be positioned in the micrometer range, highly accurate three-dimensional volume data sets are generated that represent the artworks with a spatial resolution below 0.2 millimeters. For this purpose, hundreds of individual X-ray images of the Bronzes are acquired from a wide variety of angles. The measurement time of the objects averaged one to two hours. The measurement data is processed with the help of computer software to produce a three-dimensional data set.

Meaningful data sets that hide no detail

These CT data sets will be merged with those from photogrammetry for a holistic representation of the objects. Very typical challenges in digital space will be considered: Issues of goal-oriented scaling of data sets that vary over a wide range, accessibility to user communities ranging from research colleagues to the general public. Questions about the obsolescence of storage media and the associated need for data migration are also discussed in the project.

An important aspect of X-ray computed tomography concerns radiographic dating: Quartz-containing technological residues from the casting process, which adhere to the inner walls of objects, can be used for dating by luminescence techniques such as thermoluminescence or optically stimulated luminescence. In the course of the project, test sands will be irradiated at EZRT under controlled conditions to ensure that high-energy CT does not affect the subsequent dating of the Bronze in individual cases.

In this research cooperation between the Fraunhofer Development Center X-ray Technology EZRT and the Staatliche Museen zu Berlin, new insights into art technology and production techniques are being gained in close consultation with the owners, which ultimately also represent a prerequisite for the eventual creation of detailed copies. Together, the foundations of a modern conservation science documentation and three-dimensional visualization of the artworks are being developed, which will be made available to the academic and general public.

Note for journalists

For press inquiries about CT, please contact Fraunhofer IIS: Thomas Kestler, thomas.kestler@iis.fraunhofer.de, Tel.: +49 911 58061-7611. Further inquiries will be answered by the museum's press office: Timo Weißberg, Staatliche Museen zu Berlin - Preußischer Kulturbesitz, tel.: +49-/0/30-266-42-6803, mobile phone +49-/0/151-641-456-37