Industrial computed tomography (CT) has become a fixture of the modern industrial environment and is used in various sectors. Many companies now utilize several CT systems for a wide variety of tasks, from the monitoring of production processes and the sorting of objects to completeness analysis. So that companies can work efficiently with such proliferating masses of machinery, Fraunhofer IIS has developed a new data management software.

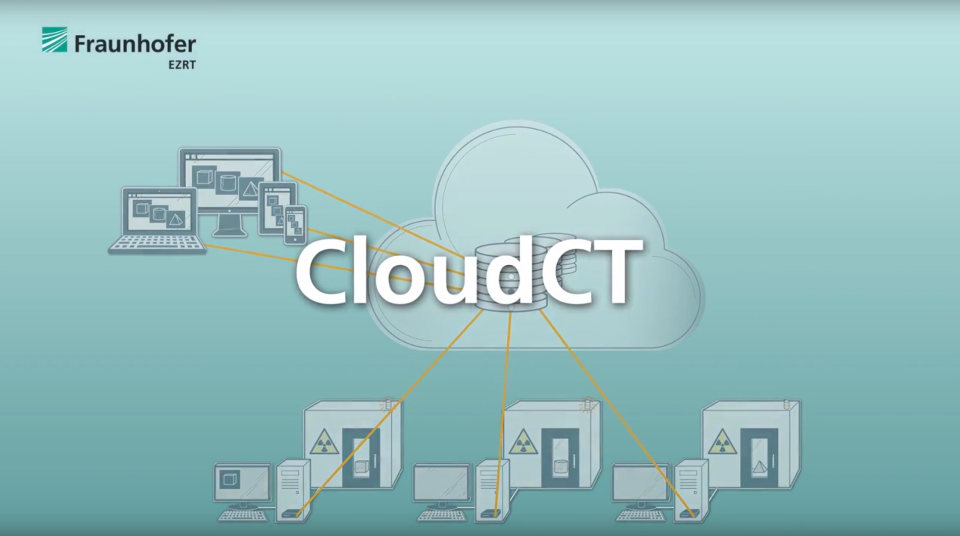

“CloudCT” significantly improves the user friendliness of CT and makes it easier to handle the resulting data volumes. The software saves all data centrally in the company’s own cloud, so users can access it from any device.

In particular, large operations running several CT systems were lacking a practical means before now that would enable them to save and access CT data centrally. In addition, users could not view data when on the move. CloudCT is a web-based CT data management system that solves this probem by enabling users to save and visualize various kinds of data that are generated and managed in the industrial CT environment. This includes information such as projection data, volume data and metadata. Now, users can access CT data from anywhere – for example, during a meeting with a client. But that is not all: CloudCT also allows users to monitor the progress of ongoing measurements and to restart them if a problem should arise.

The development of CloudCT was undertaken initially for internal reasons: “At Fraunhofer EZRT, we operate numerous X-ray systems. Because they’re situated in different rooms and even buildings, we wanted a system that would give us access to our CT data from anywhere,” explains Thomas Miller, computer scientist at the Fraunhofer Development Center for X-ray Technology EZRT.