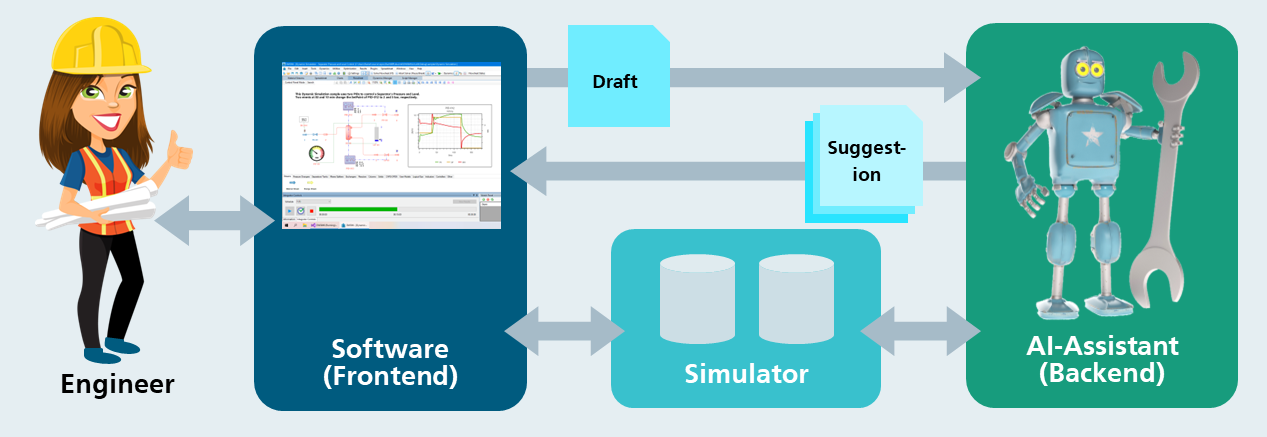

When planning chemical process plants, the challenge is to find an optimum between effectiveness, acquisition and operating costs. In addition, plants should operate as energy- and resource-efficiently as possible and produce low CO2 emissions. Even experienced process engineers often rely on heuristics and empirical values here. Artificial intelligence (AI) can support plant planning and make it faster and more effective. This has a positive impact on costs in the development and design phase. As a result, companies can lower their operating costs while reducing their CO2 emissions, giving them a competitive advantage. AI can be trained with simulations and expert knowledge to assist the engineer.

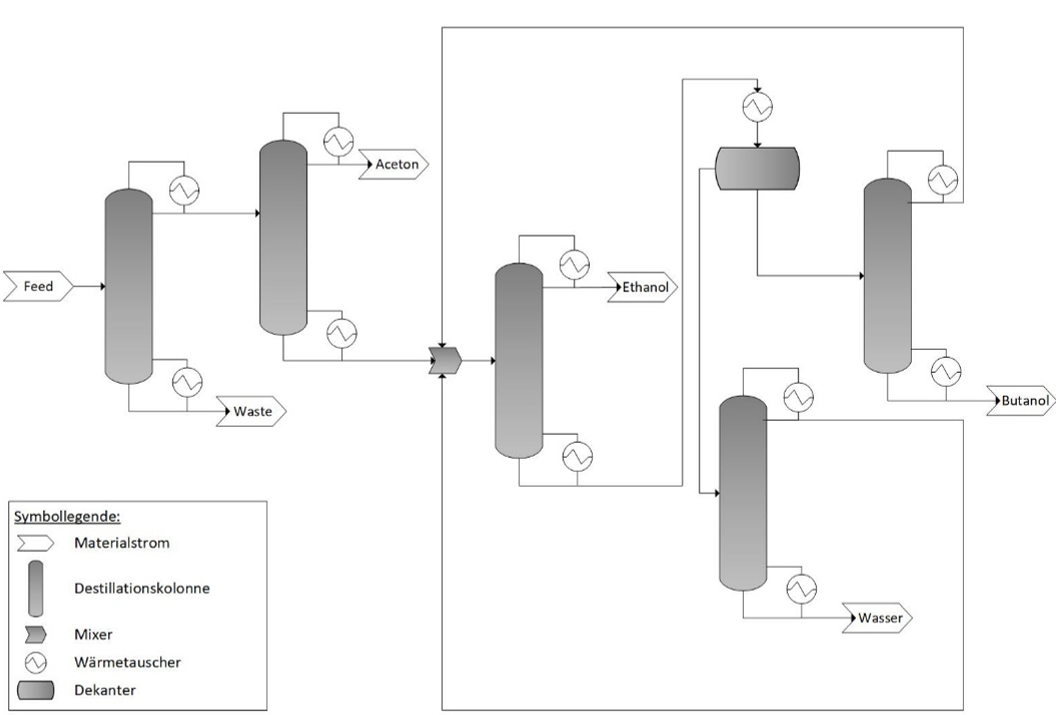

Process engineering deals with the technical and economic implementation of all processes in which substances are changed according to type, property and composition. Process engineering is needed in a variety of industries, such as pharmaceuticals, chemicals, waste management, plastics production, drinking water treatment and fuel production. Some of the tasks an engineer has to solve in process engineering are, among others, the planning of processing steps, the selection and development of necessary apparatus and machines, the determination of methods for mass transfer or the definition of necessary measurement and control technology. Finally, the engineer uses software to design a flow diagram for the desired material conversion based on the various parameters. The use of AI assistance can accelerate this process and make it more effective.