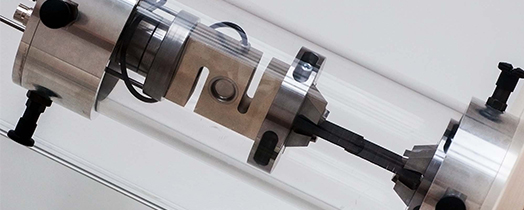

Classical 2-D and 3-D computed tomography provides information about the hidden structures inside the test objects in a static condition. However, if the specimen is subject to a dynamic change, such as motion due to physical processes, all of the conditions relevant to gathering knowledge in the respective case must be measured. The portable tension/compression device at the Fraunhofer Applied Research Center CTMT enables CT measurements to be made on tensile specimens or components while forces are introduced at the same time.

A tension device for dimensional measurement and material testing of components under stress

Dimensional measurement and material testing using nondestructive in situ computed tomography enables a wide range of samples and test objects to be inspected for deformation and crack formation as force is applied –

tensile and compressive loads, or bending loads, for example. It is also possible to determine the tensile lap-shear strength of bonded assemblies according to DIN 1465. If markers are also used in or on the object, 3D digital volume correlation (DVC) can be applied to visualize internal deformations and hence tension in the object.

It is possible to integrate the tension-compression devices into conventional computed tomography systems, irrespective of the manufacturer. The detail resolution that can be achieved depends on the size of the object under examination and the level of the load. We can apply forces of up to 15 kN at a resolution of approximately 35 µm, and forces of 1.5 kN at a resolution of 5 µm. Simply contact us for a detailed feasibility study of your project.