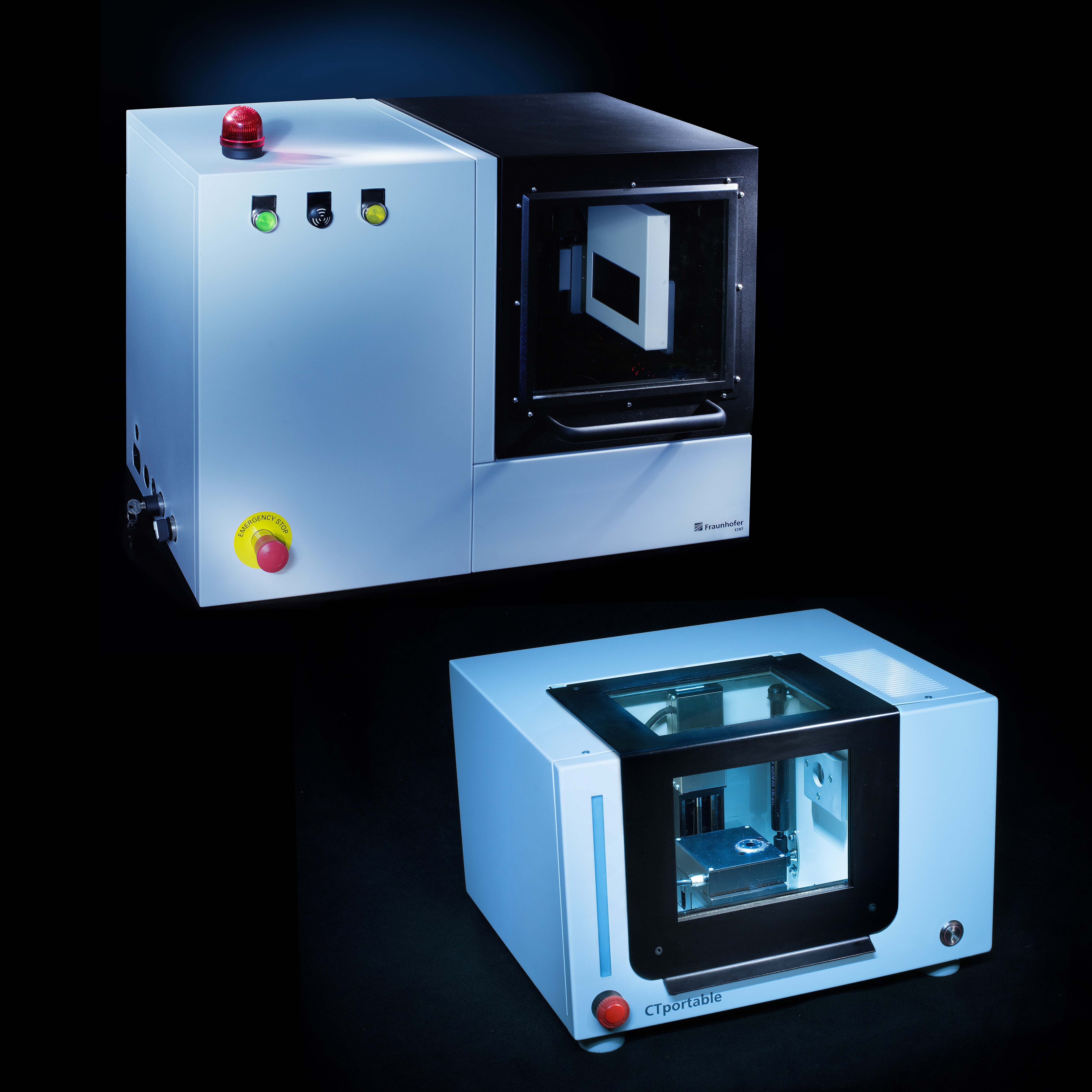

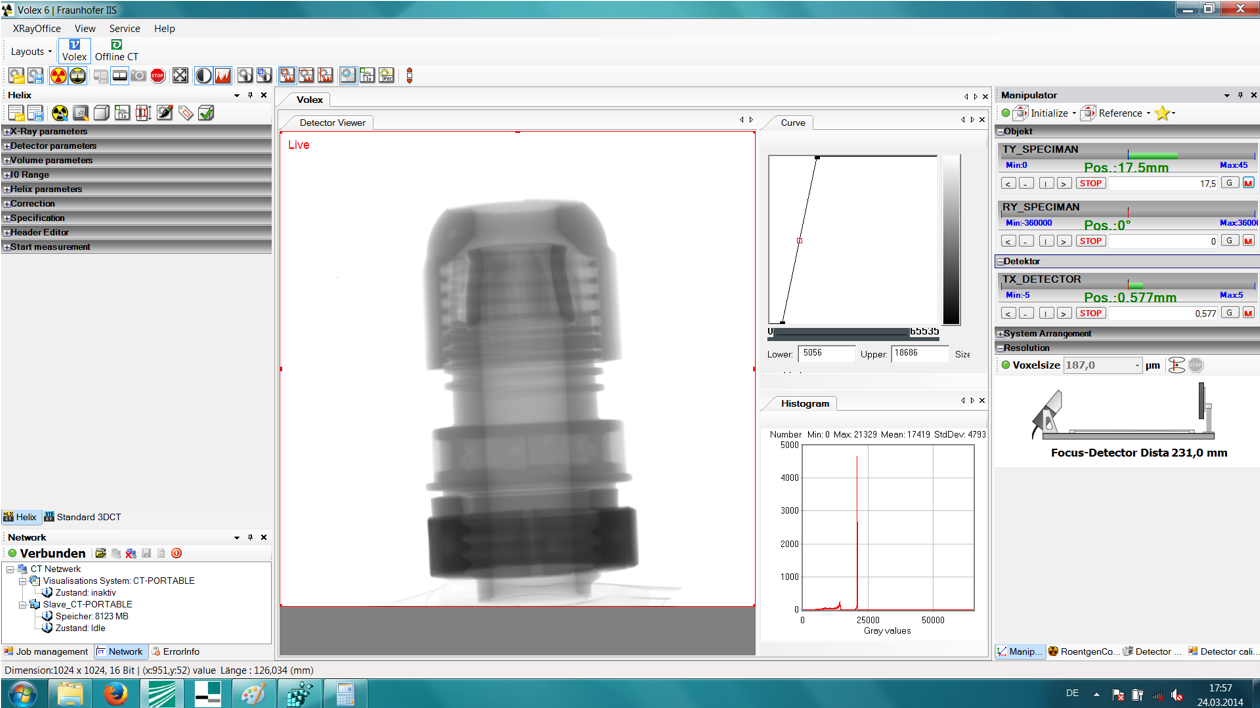

Large and stationary computed tomography systems are mostly used in X-ray technology. Due to the lack of mobility, measurements are only possible at the respective system location and sometimes complex sample environments have to be integrated there.

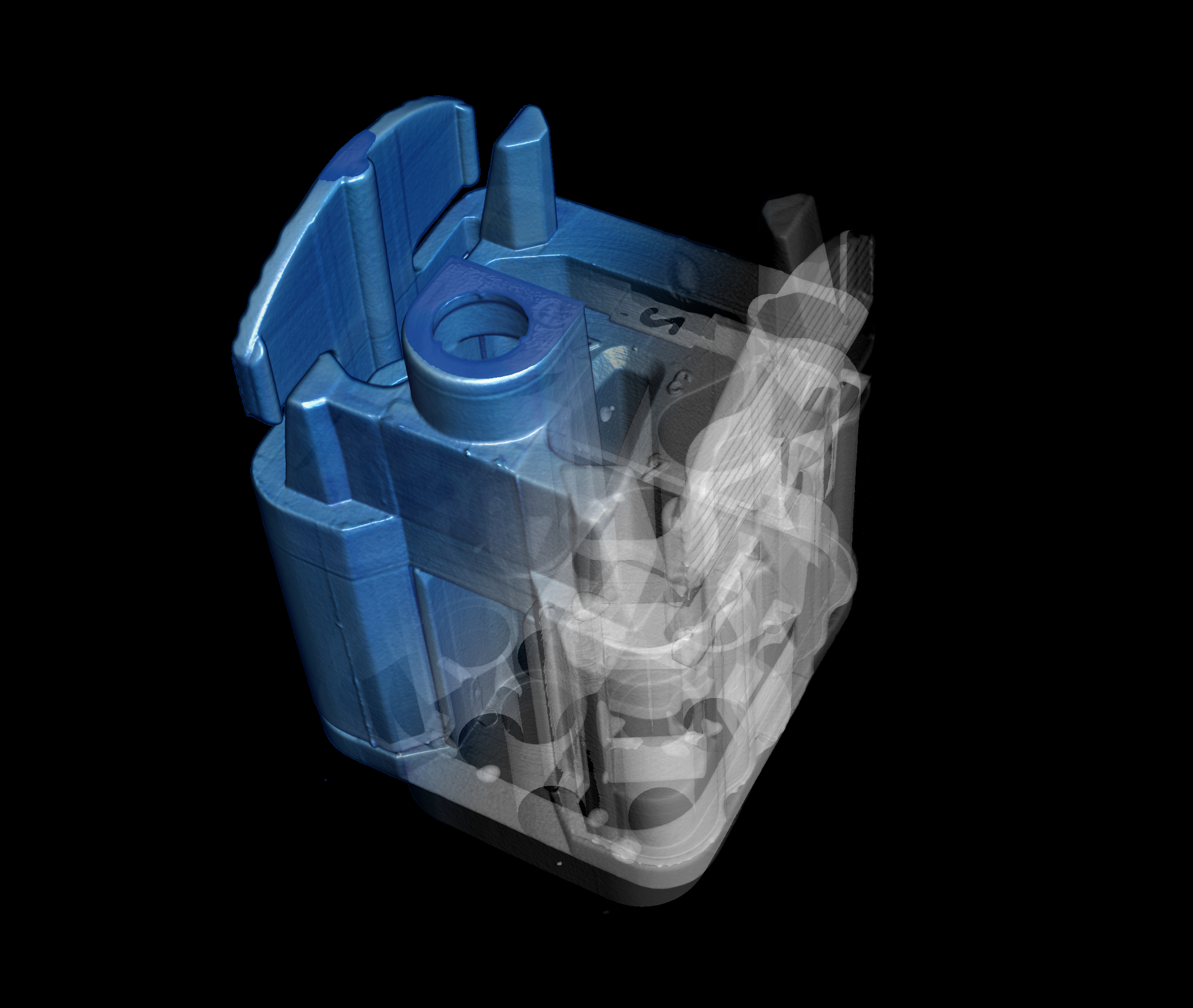

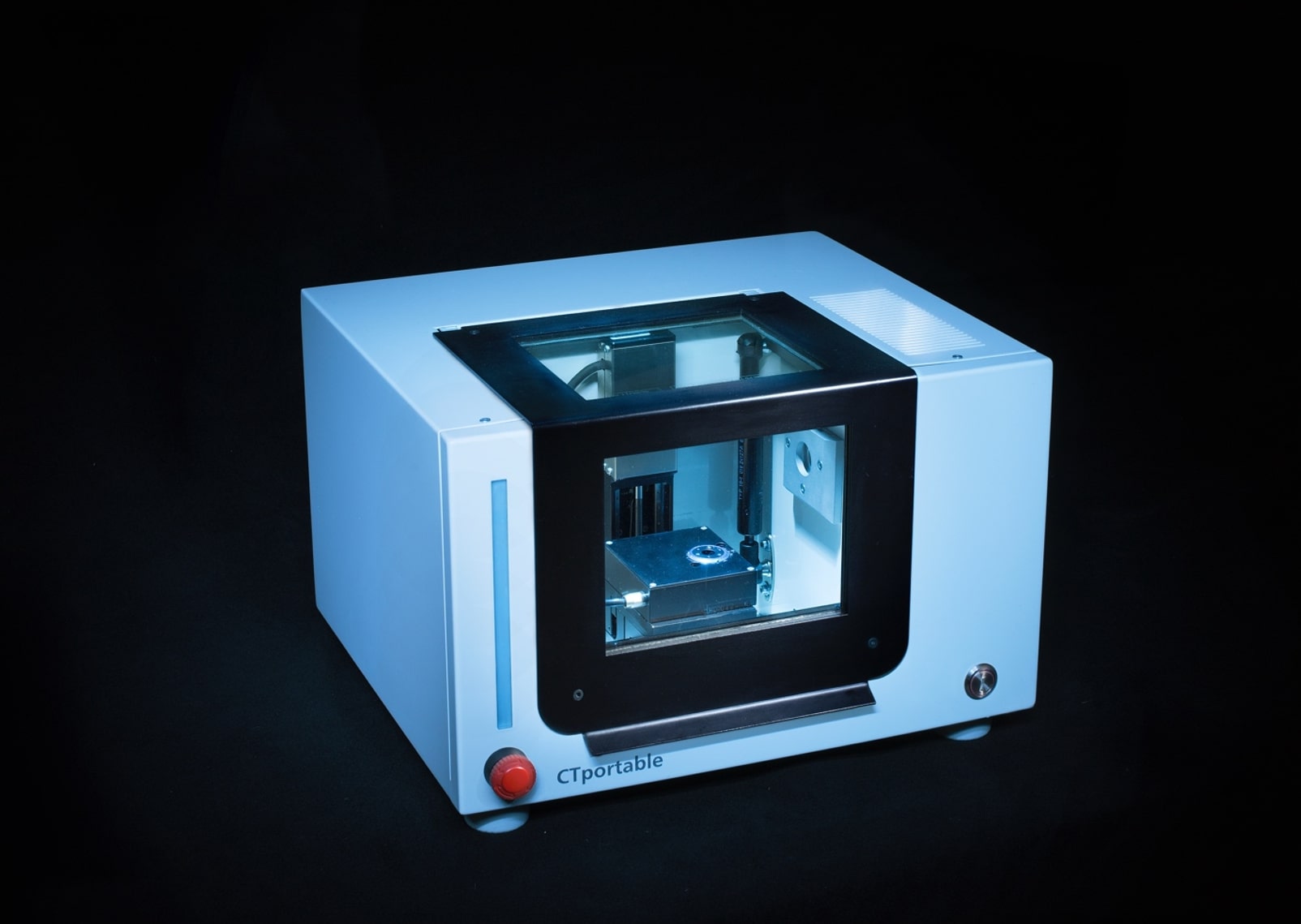

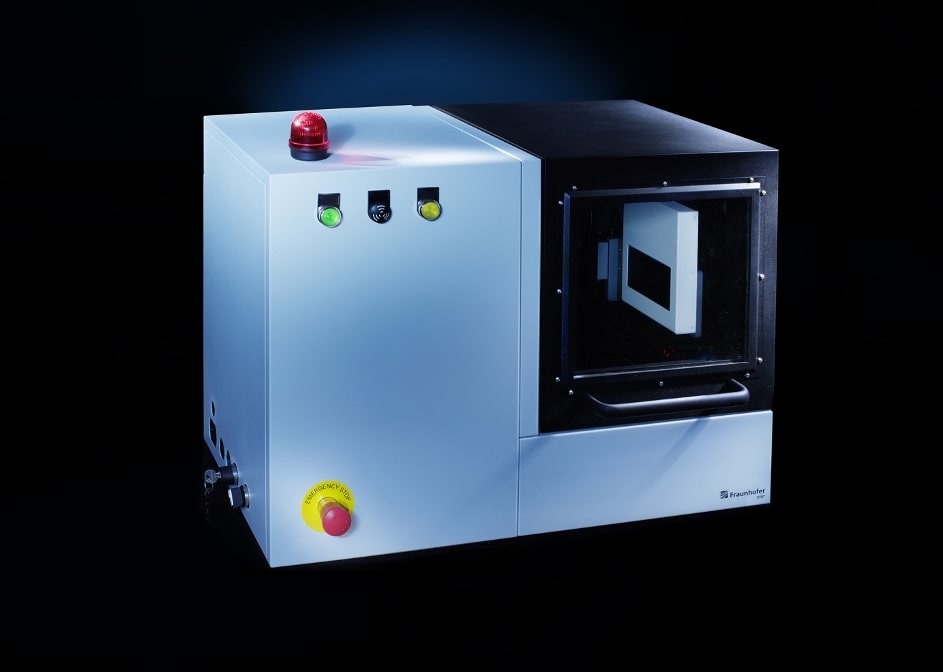

The CTportable family developed at the Fraunhofer Development Center for X-ray Technology is extremely small and portable. Thanks to the low weight and compact size, the systems can be used for measurements at changing or previously unimaginable locations.