In mining, enormous quantities of rock and soil samples accumulate both during the mining process itself and during further processing and recycling activities. These samples must be analyzed with regard to the chemical, physical, and structural properties of the rock with a view to obtaining a realistic assessment of the valuable materials they contain. By combining this analysis with insights into the spatial course of rock formations, it’s possible to boost profitability and implement further project planning in quarrying projects in a more targeted manner.

As things stand, individual components of the material must be transported away from the site for costly and time-consuming laboratory analysis.

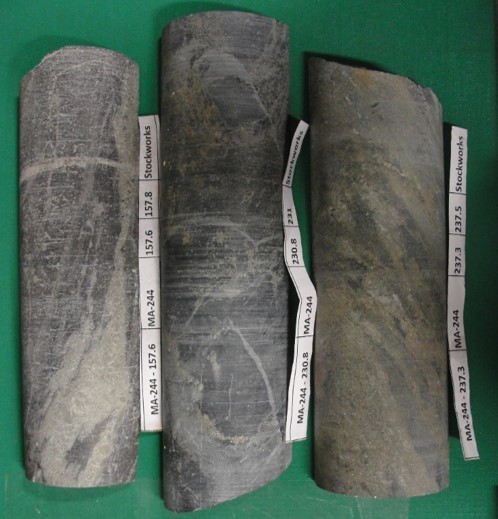

ANCORELOG - mobile drill core scanner for the determination of rock characteristics

With this in mind, the partners in the EIT RawMaterials project ANCORELOG aim to develop a mobile drill core scanner that aids the on-site classification of the mineral composition and texture of the rock.

This project will initially involve developing a prototype of the drill core scanner that uses the components listed on the right to generate datasets for the classification of rock samples.

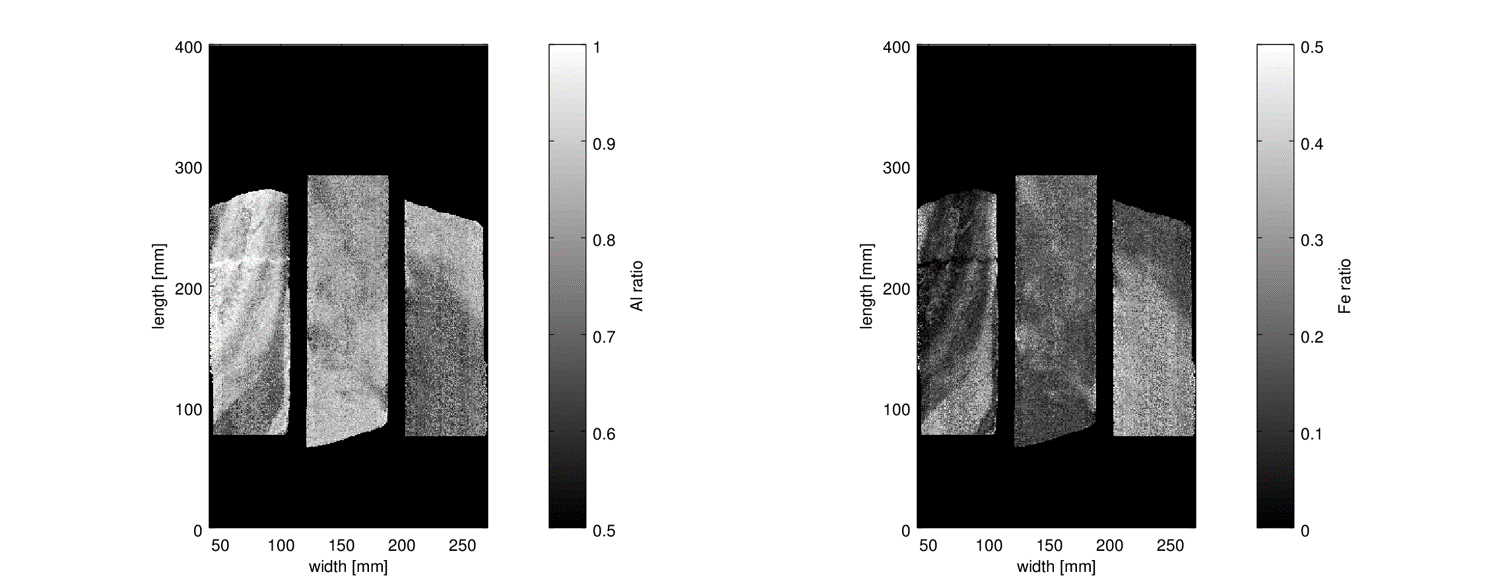

In addition to the scanners used in the prototype, Fraunhofer EZRT is carrying out tests using multi-energy X-ray transmission (ME-XRT) imaging – a technique that detects the X-rays transmitted by the sample, thereby providing information about the drill core volume. The simultaneous recording of data in multiple energy channels allows researchers to obtain information about the proportion of light and heavy elements present in the drill core. The objective of the team at Fraunhofer EZRT is to investigate whether the data obtained from within the volume correspond to those from the surface or whether additional knowledge can be generated.

The aim here is to ensure that even internal structures are not overlooked by surface methods. Alternatively, there is a possibility that surface structures do not continue inside the drill core, in which case surface methods will overestimate the valuable material content of the core.

If the ME-XRT experiments carried out as part of the project seem likely to bring added value to the analysis of drill cores, these methods could be incorporated into a future drill core scanner.

The consortium of the EIT RawMaterials project ANCORELOG is made up of European companies, research institutions, and universities. Researchers from Fraunhofer EZRT contribute by providing expertise in relation to portable X-ray systems and intelligent data processing and interpretation with the help of advanced algorithms.

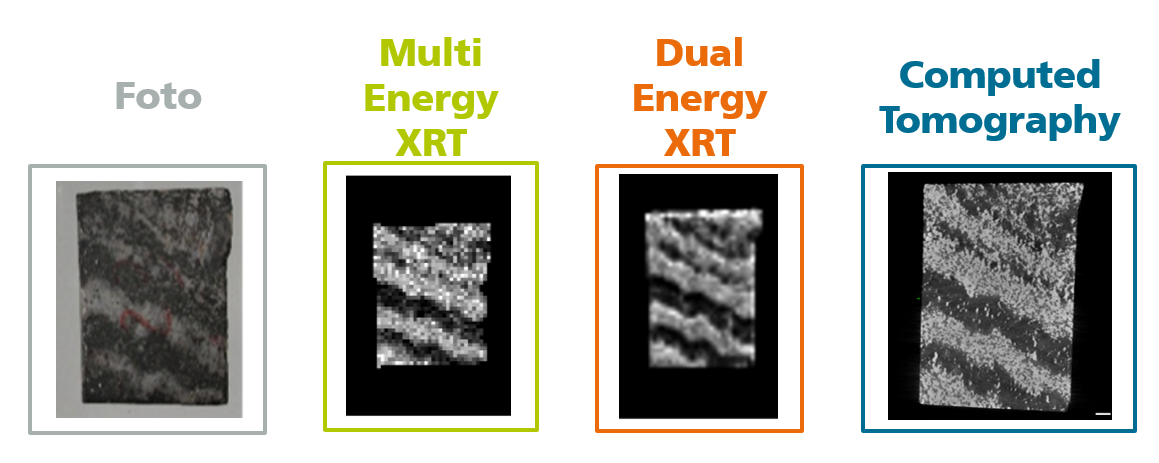

Photograph of the “banded iron formation” (BIF)

ME: Concentration of materials with a higher atomic number (valuable iron) from the multi-energy algorithm

DE: Concentration of materials with a higher atomic number (valuable iron) from the dual-energy algorithm

CT: Cross-sectional image of the “banded iron formation” (BIF)

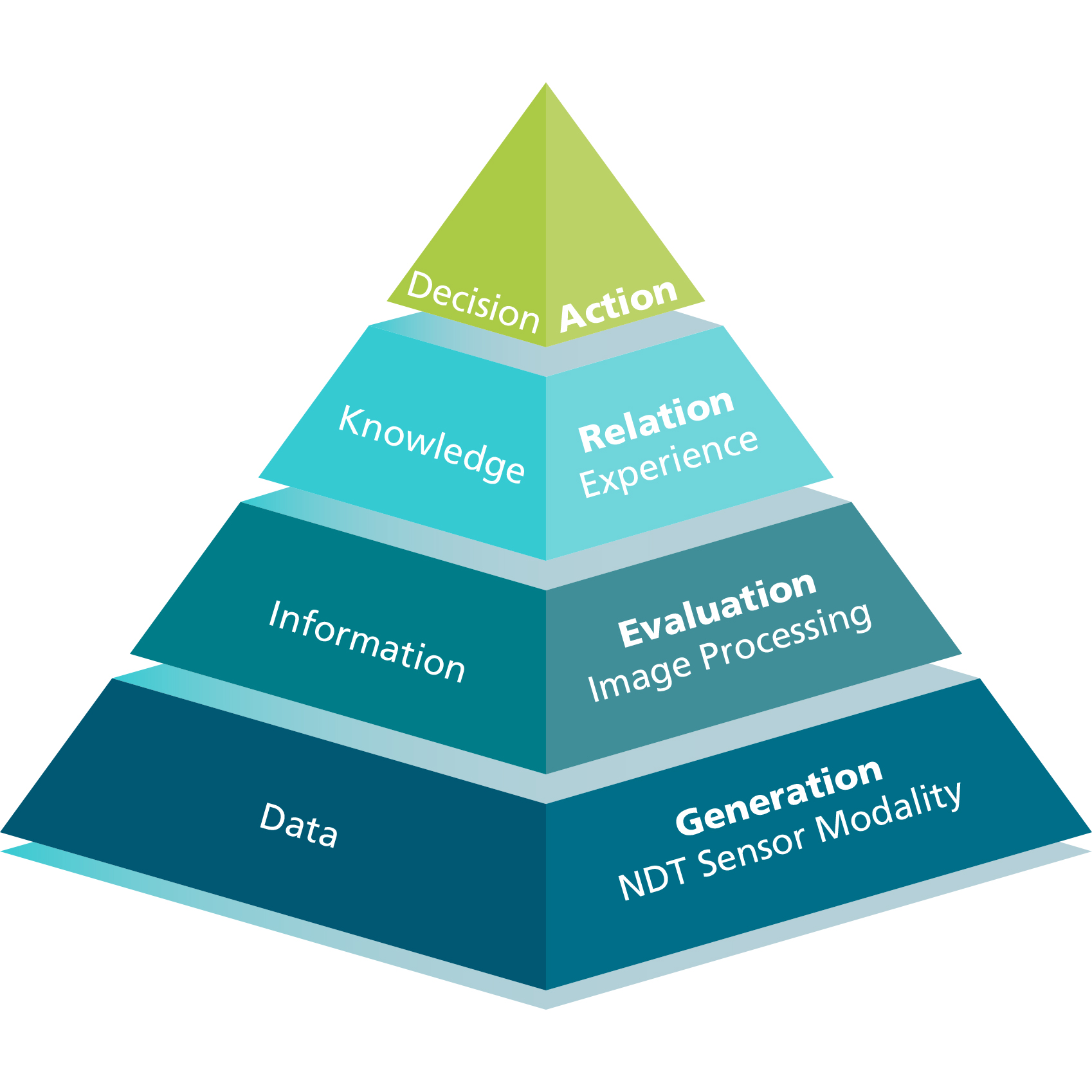

Automated decision-making processes thanks to smart classification algorithms

From the quantities of data obtained by ANCORELOG, it will be possible to extract targeted information using intelligent software-based methods in order to introduce autonomous decision-making to the evaluation of rock qualities.

This will serve as the foundation for evaluations based on objective decision-making criteria. In the context of the mining industry and the ANCORELOG project, this could entail the semiautonomous analysis and interpretation of mineral composition and rock textures. As part of this process, smart classification algorithms would translate measured properties (“big data”) into geological, geotechnical, and geometallurgical information (“intelligent data”).

In addition to drilling companies and laboratories, the potential users of this newly developed product also include universities.

Literature considering ANCORELOG

Firsching, M.; Bauer, C.; Wörlein, N.; Wagner, R.; Lucic, J.; Orberger, B.; Ennen, A.; Dubos, J. L.; Banchet, J.; Milazzo, J.-M. Potential of 3D computed tomography for industrial waste agglomerates, SME Annual Conference & Expo, Phoenix, AZ, 24 February 2020 (Presentation).

Bauer, C.; Wagner, R.; Firsching, M.; Orberger, B.; Lucic, J.; Ennen, A.; Wörlein, N.; Dubos, J.L.; Banchet, J.; Milazzo, J.-M.; et al. Recycling of Mn-processing dusts: Quality control through 3D computed tomography. In Proceedings of the IMPC 2020: International Mineral Processing Congress, Cape Town, South Africa, 18–22 October 2020. 3551-3560.

Bauer, C.; Wagner, R.; Orberger, B.; Firsching, M.; Ennen, A.; Garcia Pina, C.; Wagner, C.; Honarmand, M.;Nabatian, G.; Monsef, I. Potential of Dual and Multi Energy XRT and CT Analyses on Iron Formations. Sensors 2021, 21, 2455-2475. https://doi.org/10.3390/s21072455

Bauer, C.;Wagner, R.; Orberger, B.; Firsching, M.; Wagner, C.; Boudouma, O.; Siahcheshm, K. Dual and Multi Energy XRT and CT Analyses Applied to Copper-Molybdenum Mineralizations in Porphyry Deposits. Mater. Proc. 2021, 5, 27 .https://doi.org/10.3390/materproc2021005027 (Presented at the International Conference on Raw Materials and Circular Economy, Athens, Greece, 05-09 September)

Bauer, C.; Wagner, R.; Orberger, B.; Firsching, M.; Ennen, A.; Garcia Pina, C.; Wagner, C.; Honarmand, M.;Nabatian, G.; Monsef, I. Economic evaluation of iron formation using Dual and Multi Energy XRT and CT analyses. Emc2020: 3rd European Mineralogical Conference, Cracow, Poland, 29 August – 02 September 2021 (Presentation).