The »Mobile flexible CT system« project was processed using agile project management and divided into sub-projects / phases. Microvista was informed about the status at all times and was able to actively intervene in the project and make adjustments. In this way, we not only realize a market-independent and transparent solution for, but also with our customers, tailored to their problems, especially in terms of costs and performance!

The first two phases examined whether and possibly how the client's requirements for a mobile CT system can be met with systems and/or components currently available on the market. The following work packages were derived and processed:

- Workshops with the aim of improving mutual understanding of the workflow and the task. Determination of reference components.

- Market research / overview of systems and components with the aim of finding suitable components or an existing system basis for »mobile CT«.

- Measurements on reference components at the EZRT with the aim of establishing a comparison and demonstrating potential for improvement compared to the current status at Microvista

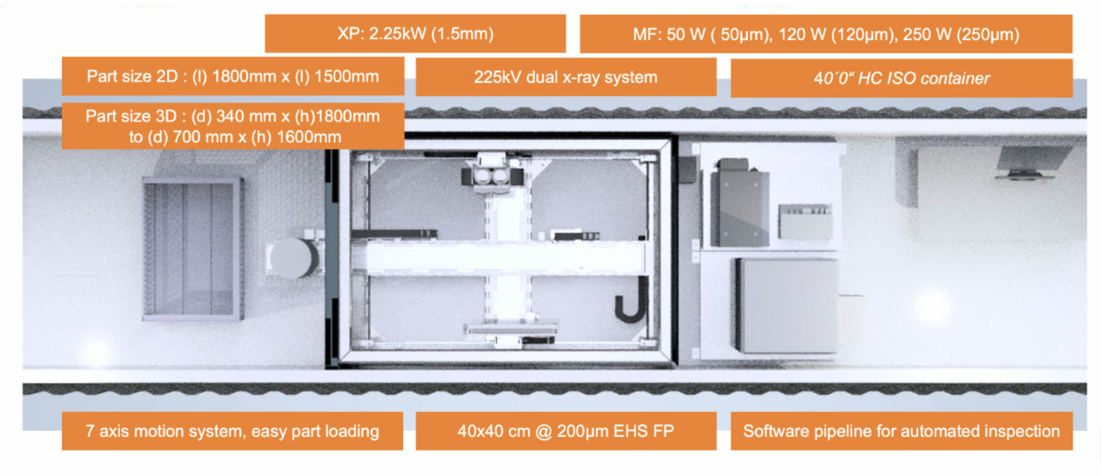

- Mechanical engineering concept and visualization of the edge bindings with the aim of determining maximum exposure geometries with a sensible beam direction, taking into account real conditions, as well as creating a concept to be able to start the implementation process with possible suppliers.