Printed circuit boards (PCBs) from waste electrical and electronic equipment (WEEE) constitute a valuable material flow, as they contain important raw materials such as gold, copper, palladium, tantalum and silver.

However, consumer electronic devices, information and telecommunication technology, and the growing number of smart devices pose a problem for the recycling industry: In order to determine the value of a larger amount of PCBs, they are presorted manually and the value is estimated on basis of a randomly selected sample set.

This process is relatively slow and prone to error. There are currently no suitable methods for determining the exact value of large quantities of PCBs that offer a high degree of accuracy as well as high throughput.

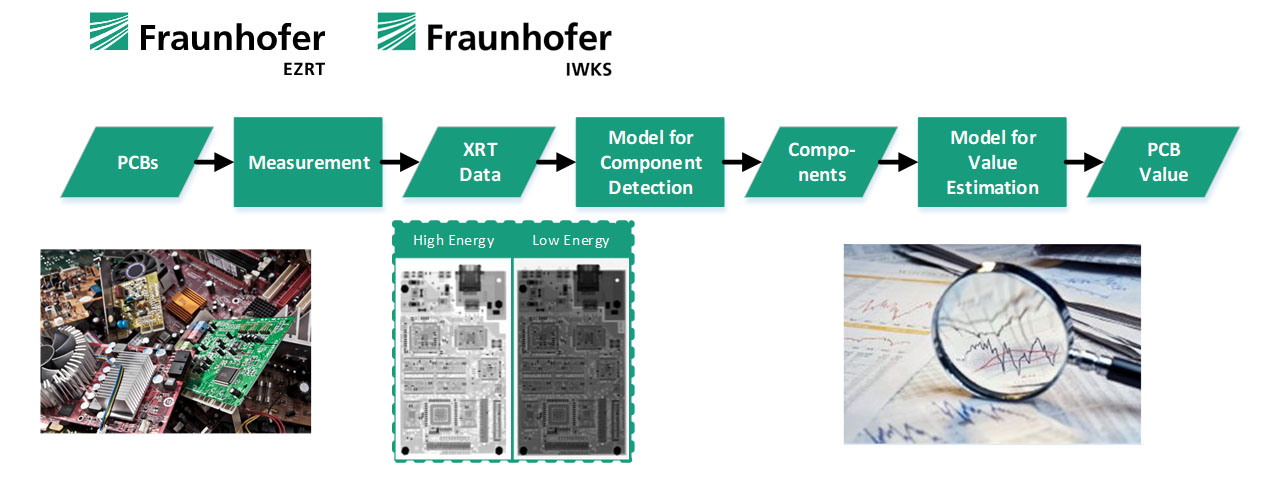

The aim of the “PCBcycle” project is to develop a solution that provides a complete online evaluation of the PCBs, enabling them to be sorted subsequently.

The result is a sorting system and process for the automatic sorting of waste printed circuit boards (WPCBs). The estimated value of the WPCBs can then be used to decide whether manual sorting and removal of valuable components is economically viable.