XXL computed tomography

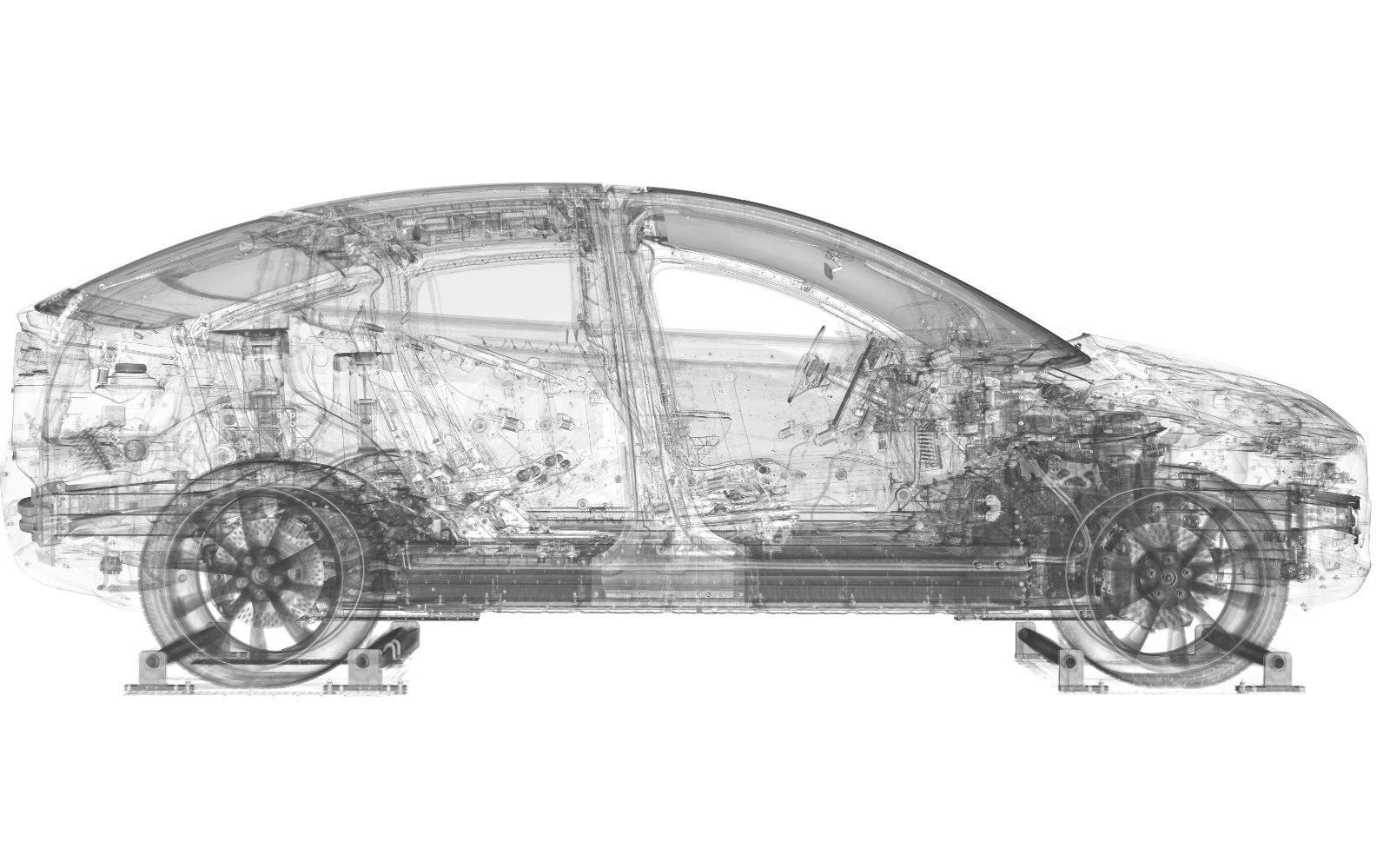

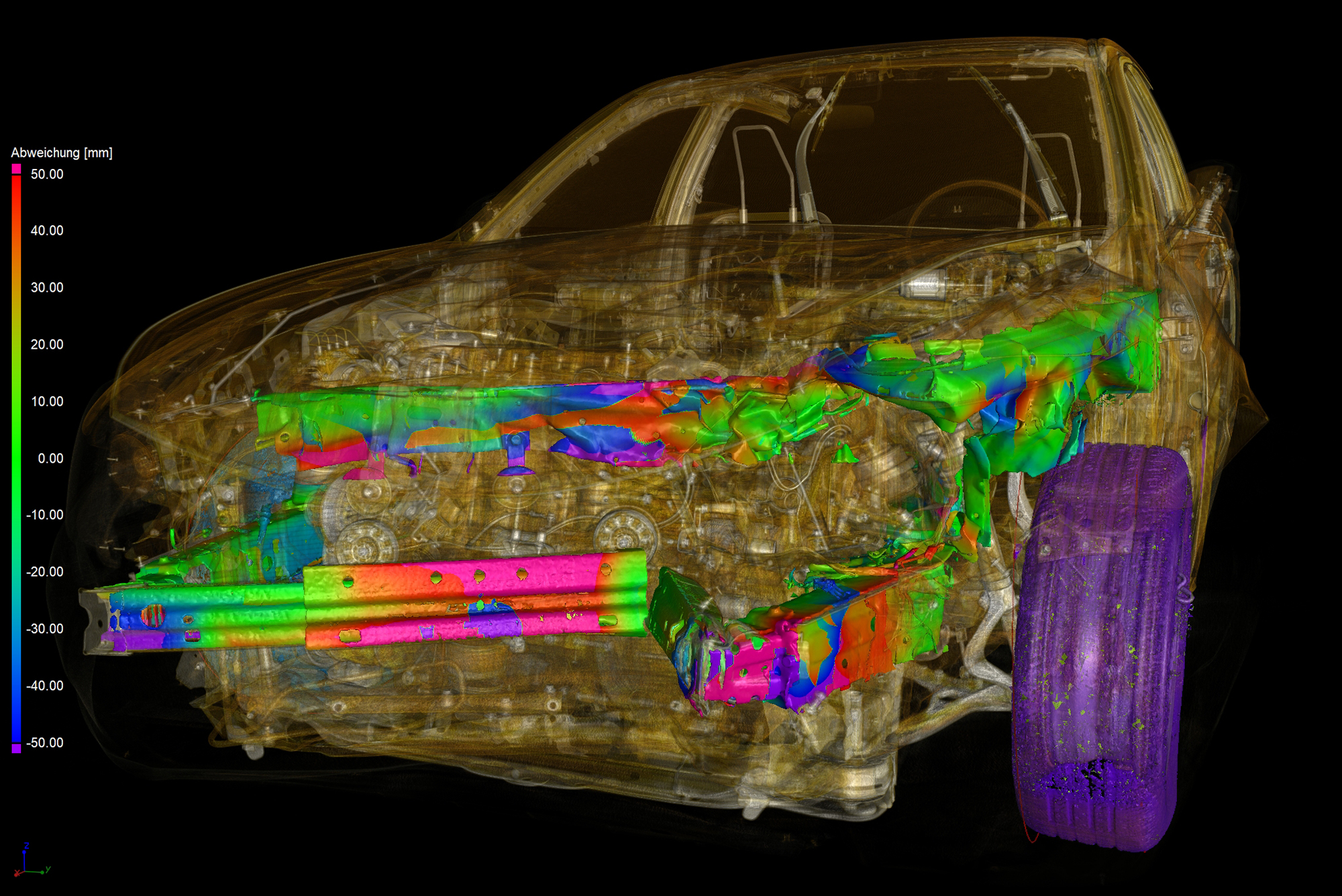

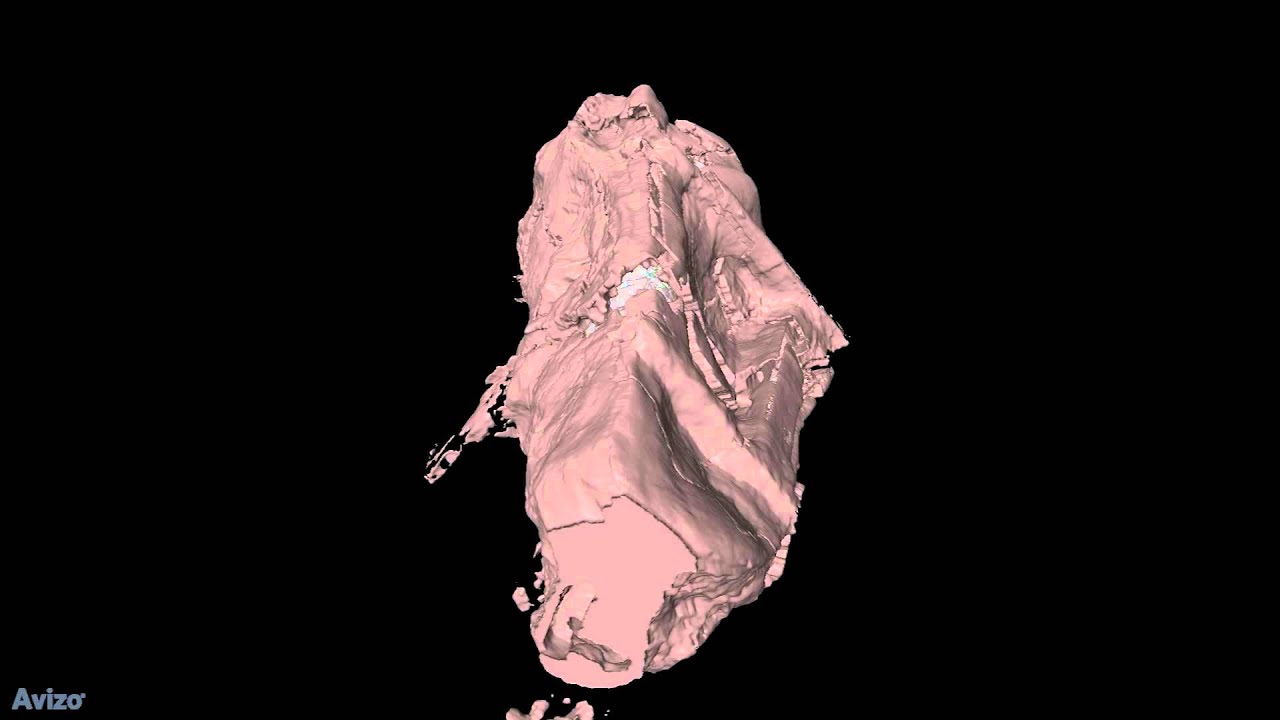

The development of complex products is hardly imaginable without modern 3D tools. Knowledge of the geometrical characteristics and the interaction of internal and external structures enables decisive optimizations of the product in the development process and beyond. Whether for simulation calculations for a crash test or to ensure product quality or for detailed material analysis – 3D measurement data closes the gap between theory and practice!

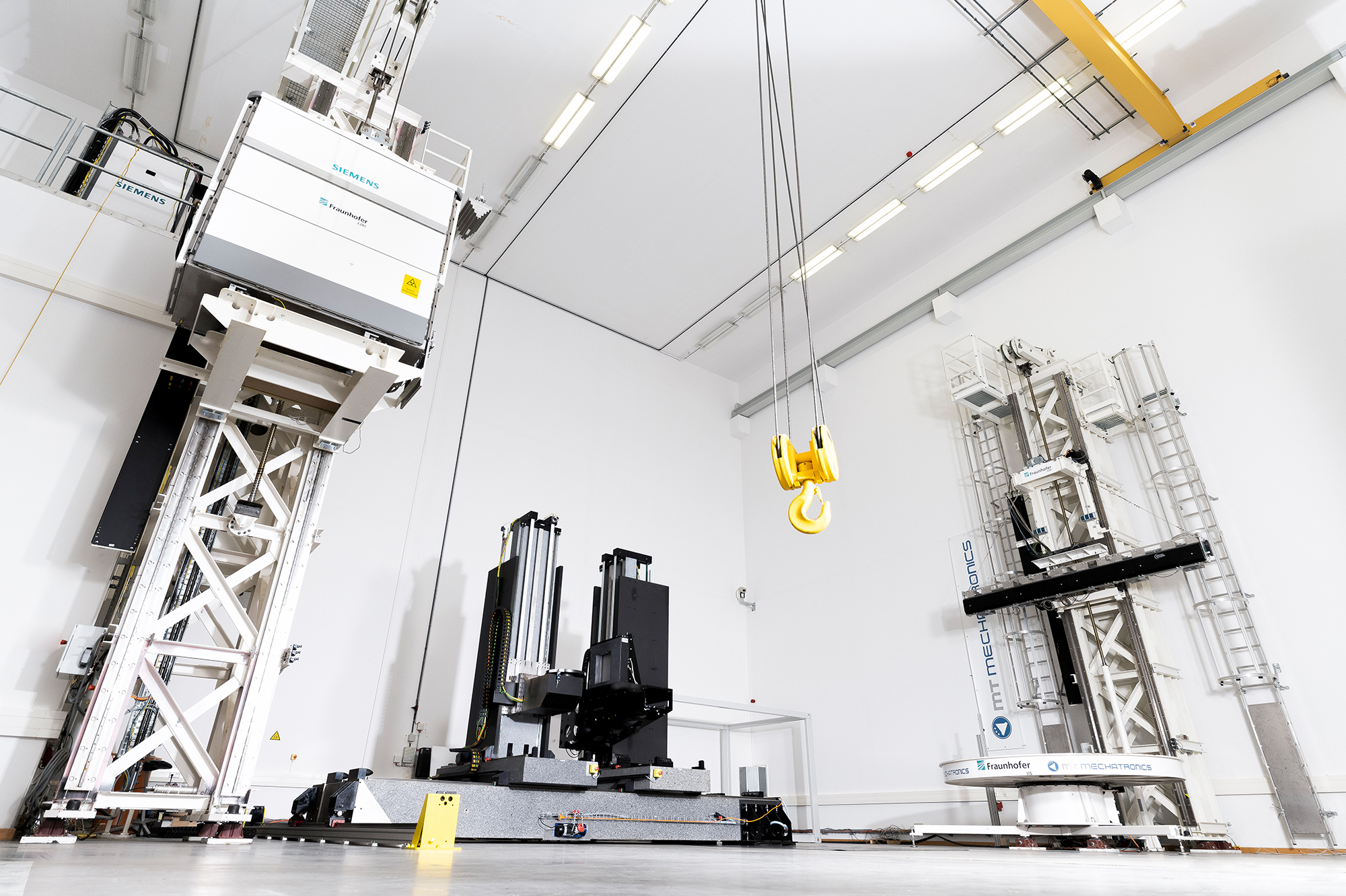

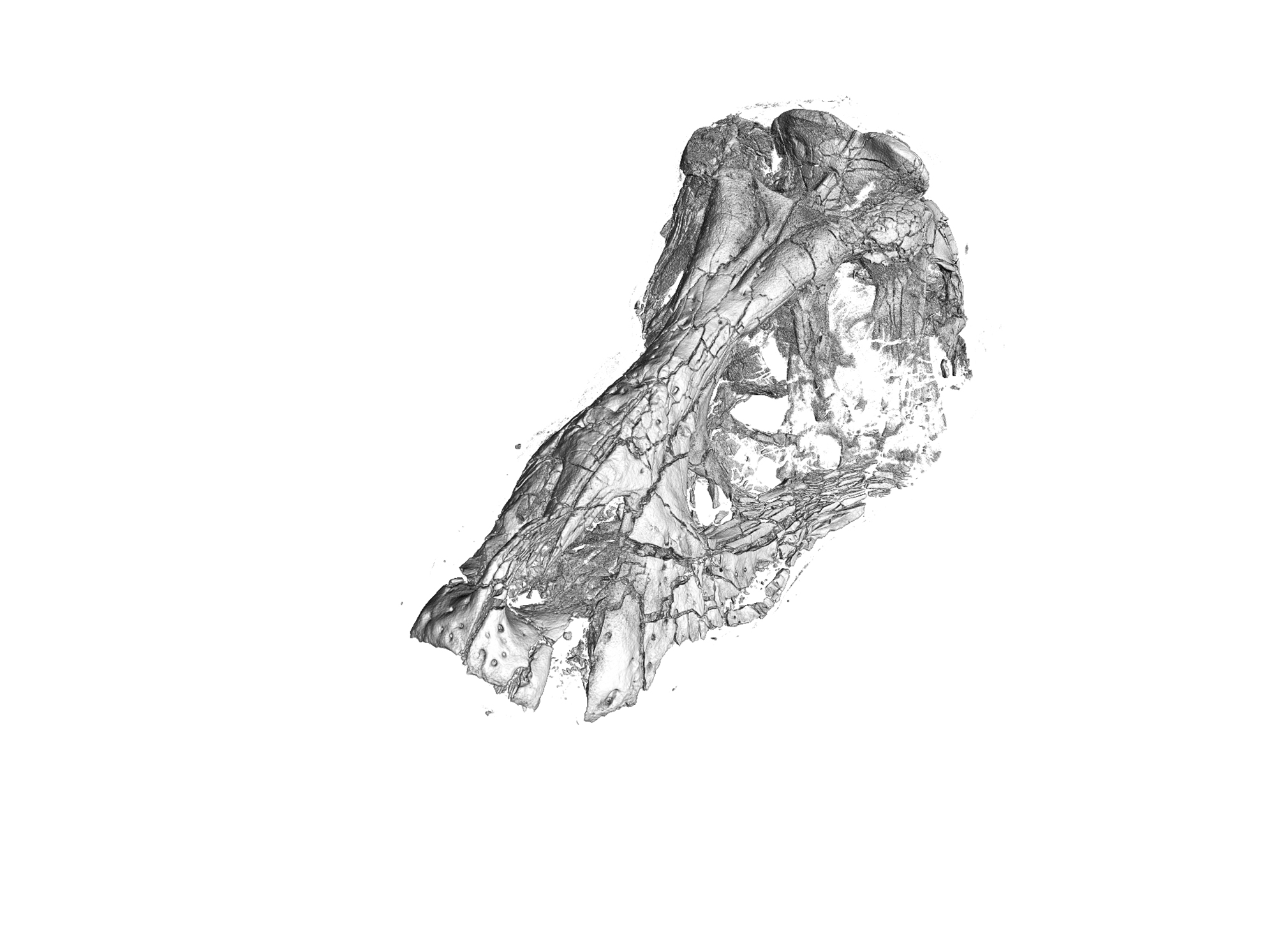

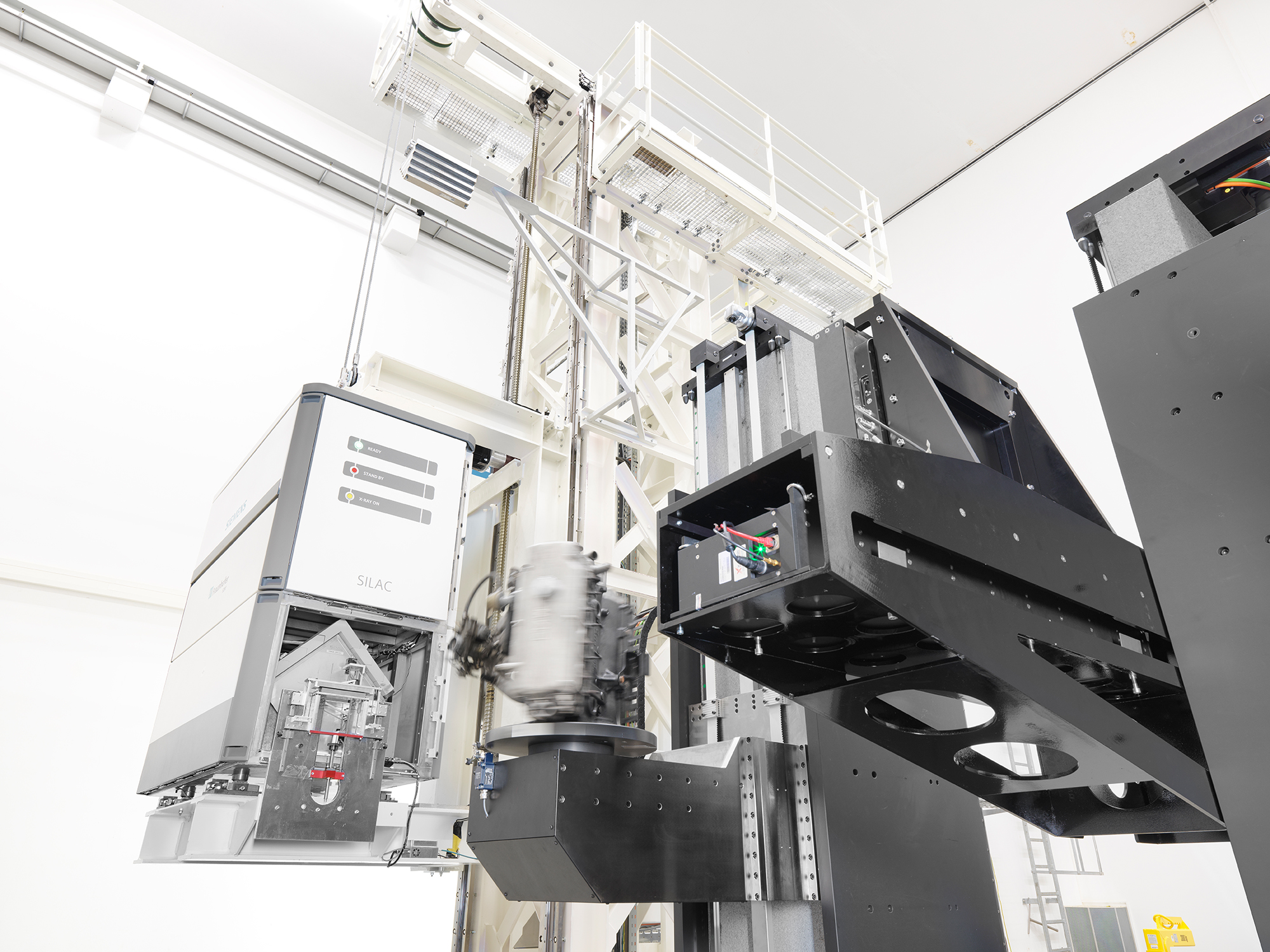

What was previously only possible for limited object sizes with a diameter below one meter can now also be realized for large objects such as, for example, assembled vehicles, sea- freight containers or aircraft parts. XXL computed tomography (XXL-CT) opens up the unique opportunity to scan large-volume objects in full in three dimensions for industry and research. The application of high X-ray energies up to 9 MeV enables not only a high level of penetration, but also a high-fidelity imaging of density for a wide variety of materials with spatial resolutions in the submillimeter range.