Through our expertise in the field of industrial CT services at the Scientific Application Center, we can provide crucial support to help you increase the quality of your products and the efficiency of your processes, minimize risks, check compliance, and bring your products more quickly to market.

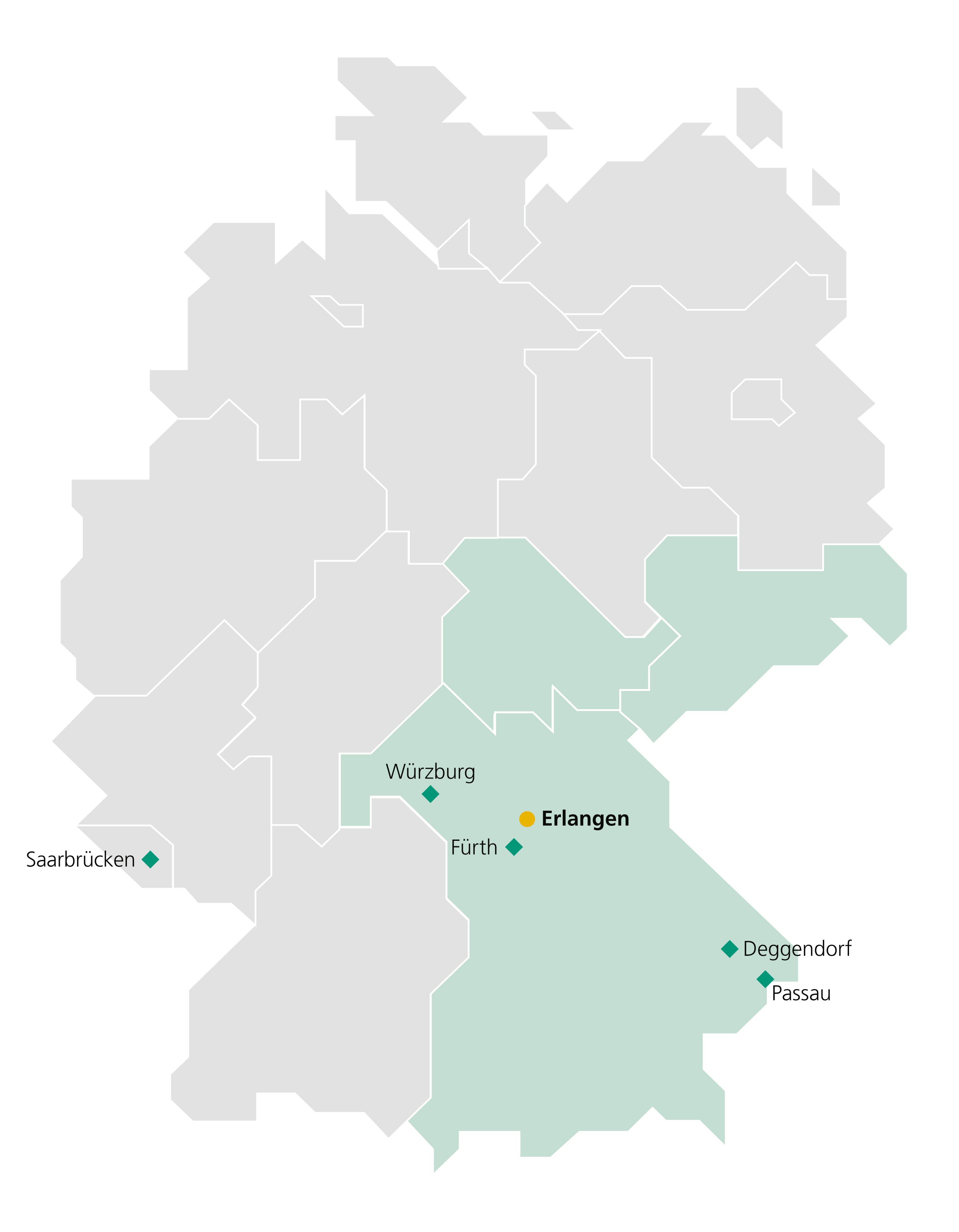

At our locations in Fürth, Würzburg and Deggendorf, we offer our customers first-rate CT services in the area of nondestructive testing.

We possess a range of industrial X-ray systems unrivaled worldwide, allowing us to carry out a great variety of testing jobs. Here, we can perform nondestructive testing on everything from objects as fine as a hair to entire vehicles or freight containers. Regardless of the application or material, our scientists offer the right solutions in domains as diverse as automobiles, power generation, foodstuffs, clothing and aerospace.