“The key factor is the homogeneity and duration of the flow through the portafilter,” says Michael Salamon from the Fraunhofer Institute for Integrated Circuits IIS. “Water needs to flow through the ground coffee as uniformly as possible without forming channels.” Salamon explains how 4D X-ray technology can be used to optimize the extraction of coffee from coffee grounds.

If your coffee tastes bad, it may be due to channeling

June 23, 2023 | X-ray technology for better coffee

Watery, acidic espresso is any coffee lover’s nightmare – and it’s often caused by a phenomenon known as channeling. As water always seeks the path of least resistance during extraction, it quickly forms channels within the ground coffee in the portafilter of an espresso machine. The effect of these channels is that the water doesn’t flow through the coffee grounds uniformly and that the components of the coffee aren’t released in an optimum fashion. All of this adversely affects the taste and “crema” of the espresso – but the problem can be avoided by ensuring the correct degree of grinding, the correct tamping pressure, and an even distribution of the grounds. This applies equally to portafilter machines and coffee capsules.

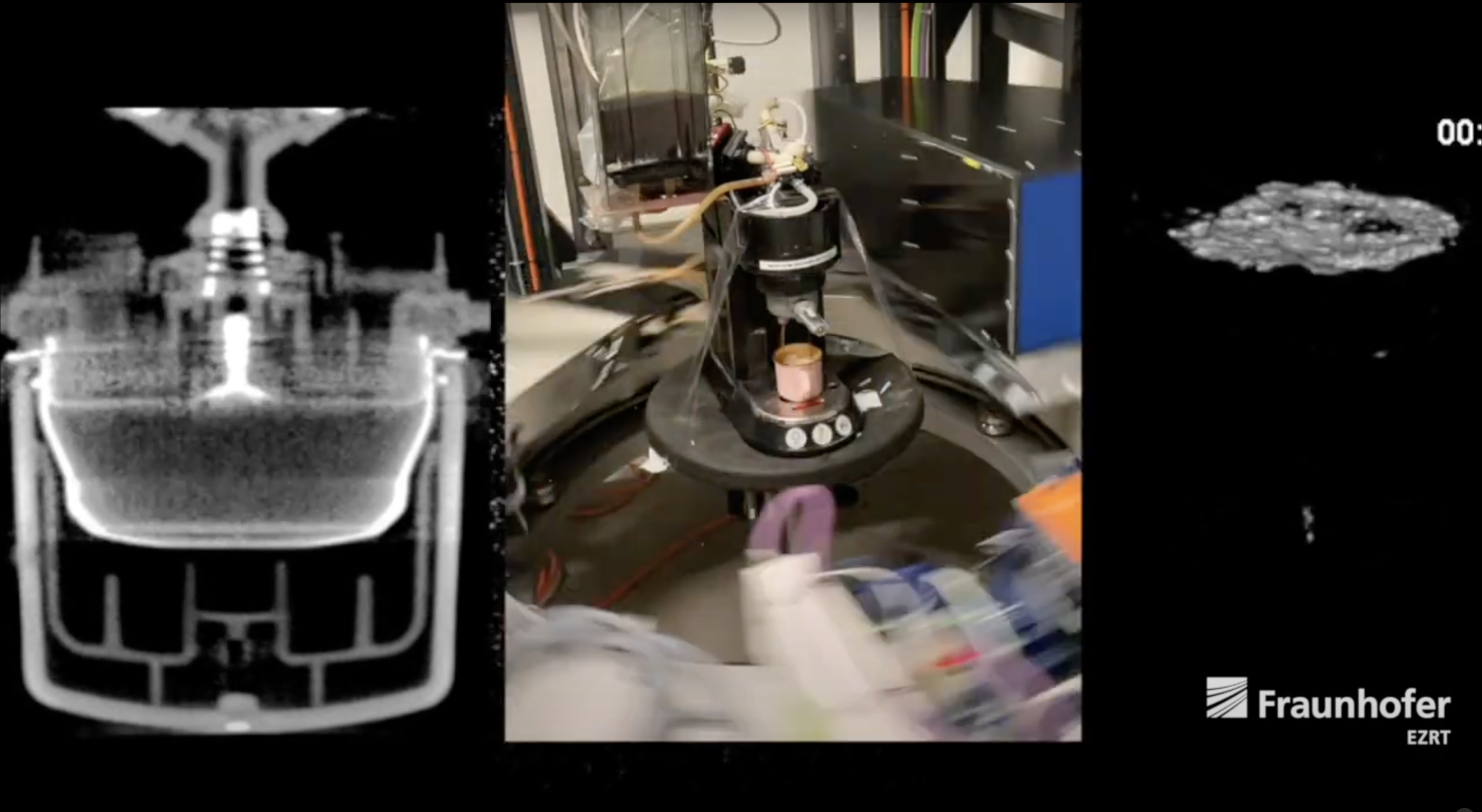

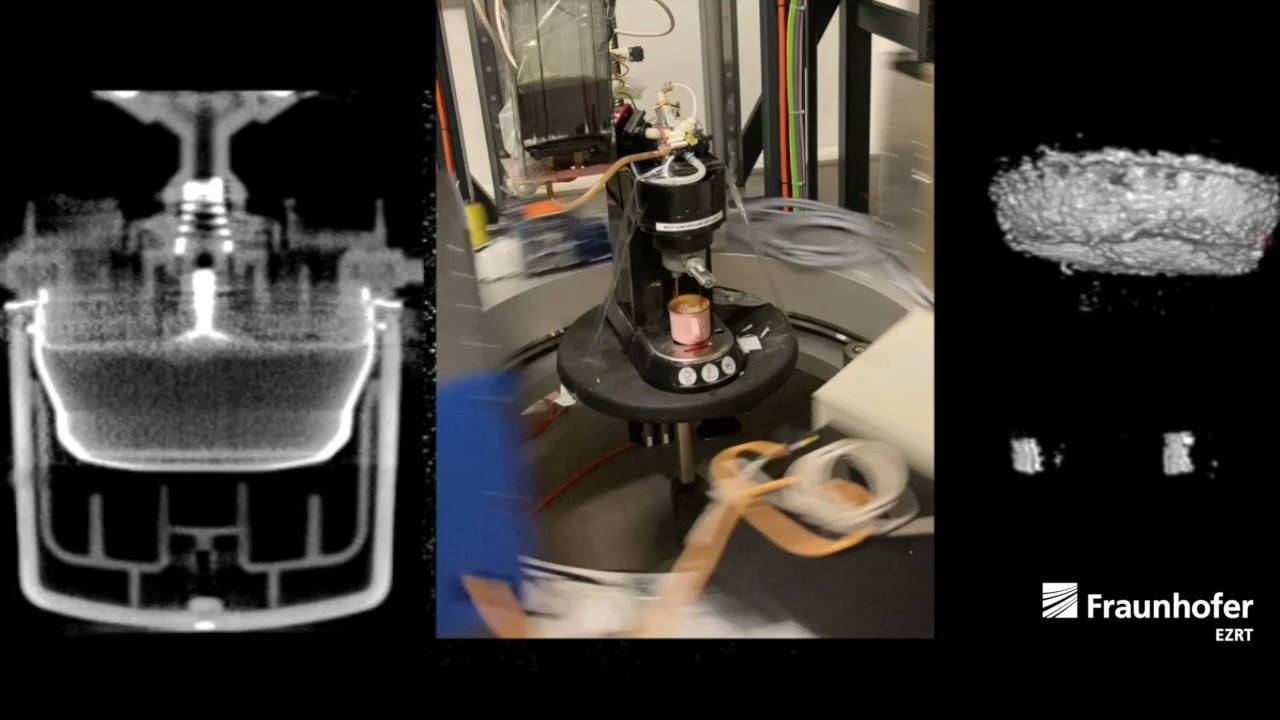

It’s no wonder, then, that manufacturers have a keen interest in ensuring that water flows through their machine without forming channels. This is where group manager Michael Salamon and his team come in. They’ve used 4D computed tomography (CT) scans to observe and take measurements of various machines during the extraction process. Their aim: to work out the ideal way of extracting coffee from coffee grounds.

Coffee – behind the scenes

“These insights into the extraction process are very useful when it comes to optimizing extraction. For new coffee preparation techniques, this is a great way of supporting the computer simulation,” says Salamon. In order to take the measurements, the machines are placed inside a horizontally rotating CT system and X-rayed from all sides. A sampling rate of up to three tomograms per second allows researchers to track the flow of water very closely at a later stage with a view to determining the optimum grinding level and the optimum tamping pressure on the coffee grounds. The technology can be used to observe processes that were previously only assumed to take place based on mathematical models and simulations. The insights into the real-life process allow researchers to validate the simulation results and to identify other factors affecting the coffee extraction quality

Video insights into making an espresso

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacy4D computed tomography

Capsule manufacturers in particular are keen to continually improve their product. Specifically, 4D CT can be used not only to analyze the extraction process in the capsule but also to depict how the water distribution changes over time. This allows the detection of potential leaks in the brewing unit, which result in excess water diluting the espresso. Here, CT scans can help to “optimize the capsule shape,” says Michael Salamon.

Fraunhofer IIS is carrying out pioneering work in this area: “To my knowledge, we’re the only ones doing it on this scale.” A paper on the results is to be published shortly – good news for coffee lovers worldwide!

Text by Lucas Westermann, Fraunhofer IIS editorial team