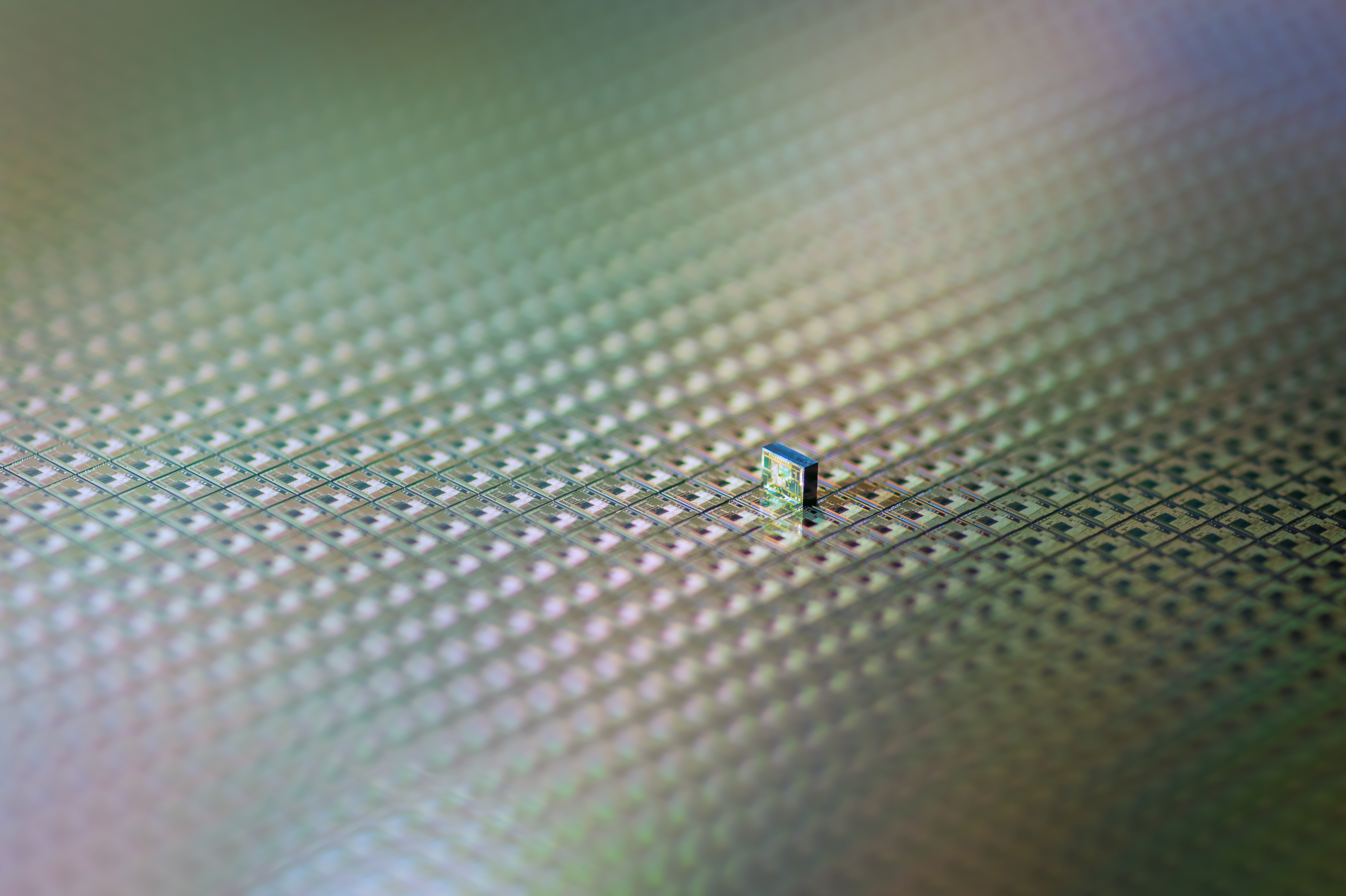

Furthermore, the staff of small and medium-sized enterprises often lack the necessary microelectronics expertise to keep up with trending technologies associated with the Internet of Things and the Tactile Internet. Often SME staff also have only very limited access – if any – to expensive design software. This is illustrated, for example, by the customers of the semiconductor manufacturer GLOBALFOUNDRIES, which supplies state-of-the-art systemson- chips (SoCs) – that is, integrated circuits on a semiconductor substrate.

The majority of the company’s customers are abroad, with only a handful in Germany or Europe, and none of them are SMEs. In other words, to create intelligent products and meet the needs of the market, German and European SMEs rely above all on off-the-shelf microelectronics products. This cannot be a permanent solution if the companies hope to remain competitive on the international stage.

Rapid change in the semiconductor industry is creating a digital divide

SMEs are in need of urgent assistance, as the information and communication technology sector and semiconductor industry are undergoing rapid and dynamic change. One example is the Internet of Things, which seeks to network real and virtual objects so that they can work together. The Internet of Things is intended to support people imperceptibly in their everyday activities, operating in the background without attracting attention. One option here is wearables – miniaturized computers that are incorporated into clothing and use sensors to record data such as the wearer’s pulse or the number of steps they have taken so far that day. The hurdles SMEs are facing threaten to create a “digital divide” in the corporate sector, as stated by the Commission of Experts for Research and Innovation (EFI) in its annual report in January 2017. On the other hand, the transformation currently taking place is an opportunity to turn value chains upside down, as the IoT market is not yet divided, unlike the smartphone market, for example.

A modular system for sensor nodes allows SMEs to participate in the market

How can SMEs seize their opportunity and survive this transformation? The only answer is for them to supply powerful, highly integrated, specialized solutions for next generation products. These solutions must allow a high chip packing density on the one hand and require little energy on the other. But what exactly does that mean? How can the development times for new products like these be shortened to half a year while also bringing the costs down to around half a million euros? In other words, how can the looming gap between SMEs and large companies be bridged?

These questions are the focus of a joint initiative that we have launched with GLOBALFOUNDRIES. The initiative seeks to make it easier for SMEs to access advanced technologies and corresponding system integration technologies, enabling them to participate in the market springing up around the Internet of Things. The Universal Sensor Platform (or USeP) project’s participants include not only our own Engineering of Adaptive Systems EAS division but also the Fraunhofer Institutes for Photonic Microsystems IPMS, for Electronic Nano Systems ENAS and for Reliability and Microintegration IZM, as well as the semiconductor manufacturer GLOBALFOUNDRIES. The state of Saxony and the European Union are providing around 18 million euros of support for the project under the auspices of the European Regional Development Fund (ERDF).

The project centers around modular technology that we are making available via a sensor platform. But what exactly does the term “sensor platform” mean? Broadly speaking, this is a technological platform that allows even small suppliers to meet the growing development and manufacturing requirements of next generation electronics. Just as car manufacturers provide a website – which experts call a “web front end” – where customers can tailor their vehicle to their own requirements, this modular system allows customers to assemble their own sensor nodes. The whole process is similar to ordering a car. As a result, not much engineering work is required, and there is no need for in-depth specialist knowledge on the part of SME staff.

The customers don’t simply receive a system-on-chip (SoC), such as those already supplied by semiconductor manufacturers. These chips alone are not much use to smaller companies, which lack the time and specialist knowledge required to develop them into a corresponding product. Rather, we offer a sort of “all-round-satisfaction package”: a completely finished – and tailor-made – sensor node made up of various elements. The first of these is the SoC, which is based on a GLOBALFOUNDRIES technology known as 22FDX, followed by a range of sensors from different manufacturers, as well as a power supply, a radio interface, and/ or wired interfaces – that is, communication technology that communicates with the outside world either wirelessly or via a cable. Customers tell the system what they need from such a sensor node and receive suggestions as to how these requirements can be met.

Together with a third partner from industry, Fraunhofer and GLOBALFOUNDRIES plan to found a company that will use this information to produce an initial prototype of the sensor node and that can also supply volumes running into the millions if necessary. Moreover, all of this will be achieved at a reasonable cost and within a few months. In the interests of carefully taking demand into account, we are currently looking for companies to contribute their ideas. We then aim to have the first prototype ready in 2019.

What are sensor nodes actually used for? A few examples …

However, before we take a more-detailed look at the benefits this modular system offers for SMEs, let us first consider what SMEs actually use sensor nodes for. The diverse range of applications includes multisensor solutions in the areas of production and home automation, using everything from simple sensors to highly powerful image processing systems. Let us take a large office complex as an example. If corresponding sensor nodes are fitted to the building, they can record data relating to air quality, temperature, and the number of people in the rooms – and if necessary can adjust the air conditioning accordingly. They can also optimize the elevators, for example: If the sensor nodes record the number of people in each location, or the direction in which they are moving, and relay this data to the elevator control system, the elevators can be operated more efficiently.

Another example can be found in the field of robotics. Nowadays, many of the robots working alongside human employees in production facilities have a sensitive “skin”. They use this to detect when they touch a person – and stop their movement for safety reasons. Using cameras, they can also detect when a human hand moves into their field of action. However, the scope of this detection system has so far been very limited, for example, it is difficult for a robot to look around the corner as it moves through the room. Using intelligent sensor nodes that communicate with one another wirelessly, it would be possible to provide systems of this kind with more information and to design working environments better. These are just a few examples of where sensor nodes can be used.

Contract handling and legal requirements are also being clarified

Let us now turn our attention back to sensor nodes. The platform not only makes it easy to assemble customized nodes, but also takes over almost the entire process of contract management and negotiations with suppliers on behalf of SMEs. This is a laborious task that smaller companies would struggle to cope with: Just to obtain the components for SoCs, they would have to sign numerous contracts with different suppliers and purchase the corresponding licenses at considerable cost. Now this contractual burden is no longer something smaller companies have to deal with.

Another advantage of the sensor nodes is that they feature a high-performance miniaturized computer that performs all of the necessary calculations. There is therefore no longer a need for direct access to external clouds or fogs, as with existing sensor nodes, in order to store and analyze the data streams. Instead, all of the necessary calculations can be carried out directly on the node. The security aspect is also extremely important to us as we develop the sensor platform. It will use state-of-the-art encryption technologies and meet the strictest security requirements. As a result, the sensor platform allows smaller companies to find their niche within the IoT sector and thereby to compete with large companies.