Transitioning toward industrie 4.0 in production and logistics

Technologies and Solutions for Digitalized Value Creation

As we transition toward Industrie 4.0, small and medium-sized enterprises (SMEs) in particular often lack the expertise required to assess and harness the potential that digitalization holds for their operations. It seems as though the hurdle SMEs must clear to implement new technological solutions has been set especially high: perhaps because they have insufficient knowledge to select the right technology and roll it out efficiently; because their employees have yet to acquire the required expertise; or because they are unable to measure the added financial value against investment.

As part of the “Technologies and Solutions for Digitalized Value Creation“ project, we help SMEs to develop themselves and their employees toward Industrie 4.0 and to efficiently implement the right solutions. There are various ways of getting started, which enables us to keep the hurdles lower and allow each SME to develop according to its own time frame and rollout plan. We take a four-pronged approach: practical applications, IoT platforms for straightforward data exchange, the human element of digitalization, and Industrie 4.0 organization and management.

Practical applications: Smart warehouse picking with Pick-by-Light and TRILUM

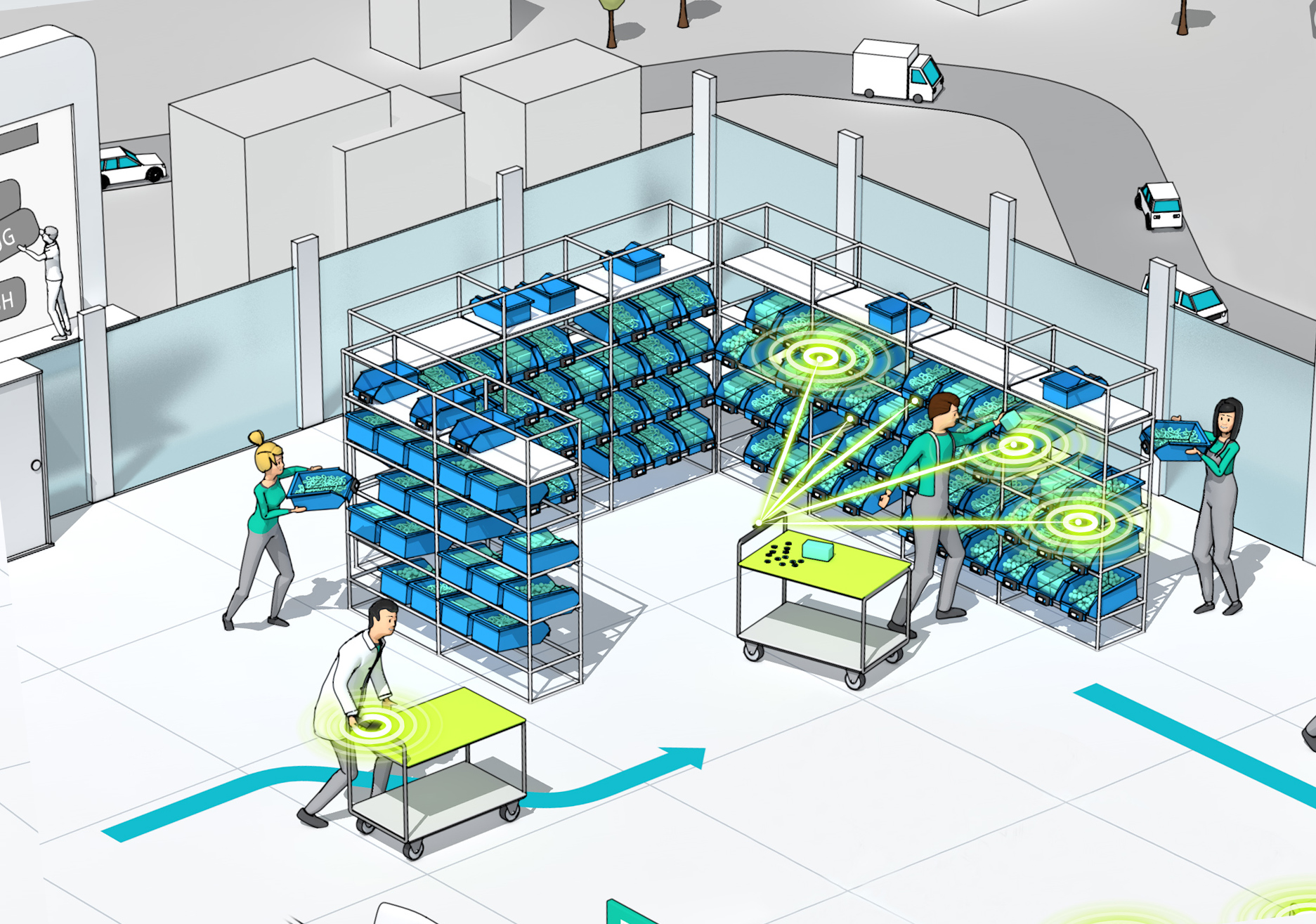

As part of the project, we identified practical applications relating to container management, in-house transport, use of tools, and picking that lend themselves well to digitalization solutions. In the process, we developed standalone technological solutions that also work on a small scale and are iteratively expandable, making them particularly suitable for SMEs.

A prime example of such an application is the wireless Pick-by-Light system for smart warehouse picking. The system affords flexibility for adding displays to bay compartments, which in turn allows pickup compartments to be reorganized quickly. Further development led to TRILUM, a mobile Pick-by-Light system for voucherless picking and assembly support that we made market-ready.

Application-oriented data platforms for flexible information exchange

Combining different cyber-physical systems (CPSs) to make one large system is difficult thanks to the patchwork of transmission protocols and data formats. Digitalized applications require information to be represented and exchanged via common data formats. This is why we are working on an open message protocol that allows individual CPSs to communicate with each other and thus provides a quick and easy way of solving compatibility issues. Corporate data that exists in different data formats is made available through semantic modeling of the data and workflows that can be interpreted by machines.

An Industrie 4.0 environment generally makes use of centrally controlled digital platforms into which the data is fed. Since there are any number of such platforms, we help companies find the right platform for each IoT use case.

As part of the project, we are also working on a new approach: we are using semantic-web and linked-data technologies to pave the way toward decentralized management and application logic. Such decentralized approaches provide users with consistent and flexible access to all relevant information while the original data owner retains data sovereignty.

How rolling out new technologies affects the workforce

The human element plays a major role in the success and the productivity of Industrie 4.0 technologies and applications. This is why we also look at each phase of digitalization from a behavioral and sociological perspective. After all, the workforce can also object to the implementation of new technologies. This makes it all the more important to uncover resistance factors ahead of time and find solutions to counteract them.

As part of the project, we are not only investigating how new IoT technologies affect the workforce, but also helping answer the question of how to successfully implement technological solutions into operations in a way that enhances motivation and productivity. To this end, we offer a range of services, including training opportunities and individual consulting and coaching sessions.

“When it comes to digitalizing production processes, the main problems are organizing the transformation process and managing the transition. Of course it’s essential to know and master the technologies involved. But it’s just as important to ensure that no one gets left behind.”

Prof. Dr. Alexander Pflaum,

Overall Project Management "Technologies and Solutions for Digitalizied Value Creation"

Organizing data-driven processes and business models

Rolling out new technologies makes economic sense only when they will make business processes more efficient, lower costs or increase sales by adding services. We evaluate companies’ business processes and the effects of rolling out the given technology, and we develop new services and business models.

We start by looking at the initial situation to measure a company’s digital maturity and work up the required target or future vision. We then build on this to define the necessary changes in terms of technology, activities, actors and organization as well as the challenges that will arise – all leading to new concepts for smart services and business models.

Successfully managing the transition

One of the biggest challenges of the digital transformation lies in managing the process holistically. It is crucial to provide companies with the support they need to quickly and easily start their individual journey toward Industrie 4.0. We lend them our holistic take on the technology and methodology of this transformation so that they can find the financial and organizational means to institute digitalization solutions right away.

- Technologies and Solutions for Digitalized Value Creation (scs.fraunhofer.de)

- Fraunhofer Center for Applied Research on Supply Chain Services SCS (scs.fraunhofer.de)

- Industrie 4.0-Selbstcheck online (survey.iis.fraunhofer.de)

- Fraunhofer SCS publications (scs.fraunhofer.de)