At a glance

The need to identify and locate objects exists in a whole host of different areas of life. Whether in an industrial or recreational setting, knowing where different objects or people are and being able to tell them apart is hugely important in all kinds of scenarios. In state-of-the-art production facilities, for instance, the localization and classification of objects on the shop floor is essential as it enables a flexible, comprehensive response to the situation at any given moment and prevents errors. At the other end of the spectrum, in the world of soccer, determining the exact position of the ball can decide the outcome of the game.

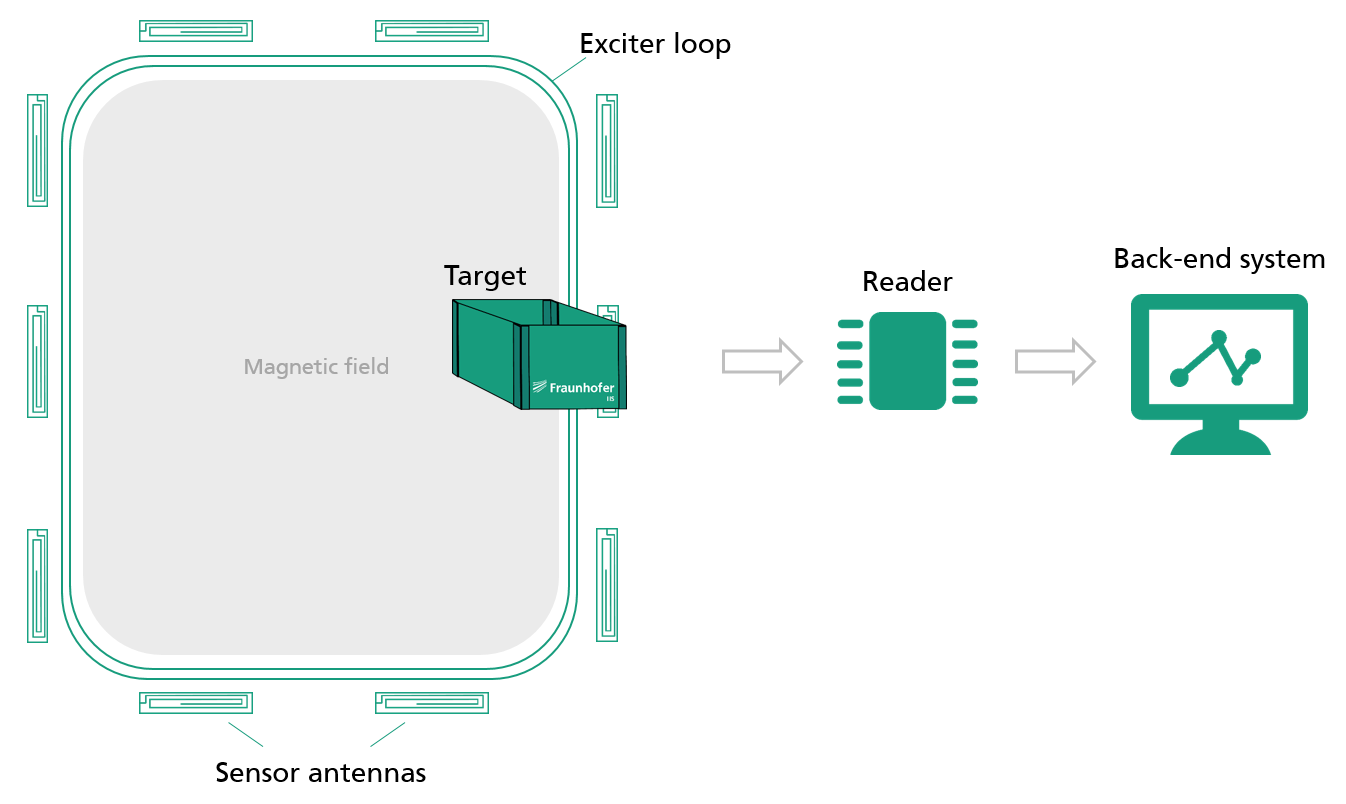

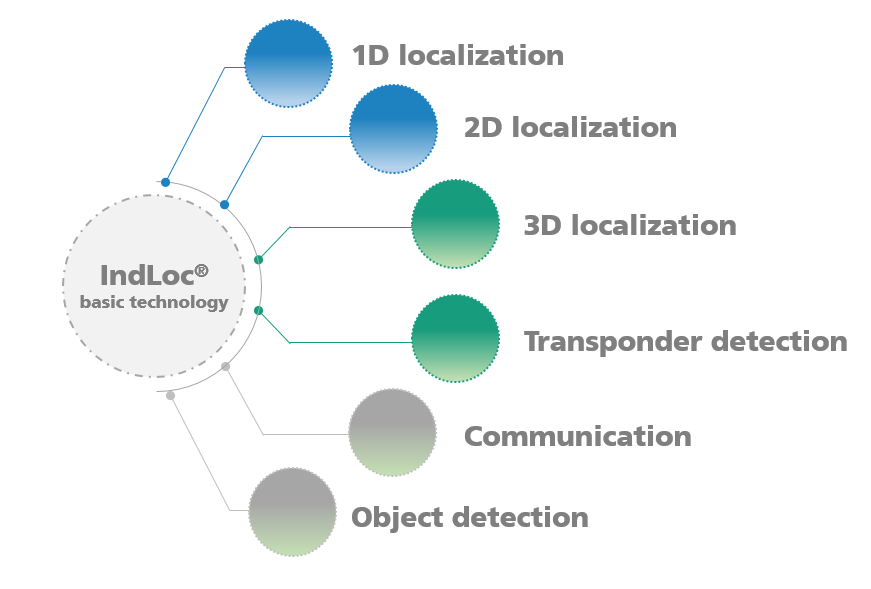

Although a variety of localization systems are already commercially available, these usually require complex sensor technology and consume a lot of energy, not to mention being very costly. In addition, unfavorable lighting conditions or metallic objects in production facilities can impair the technology’s functionality. This is what led Fraunhofer IIS to develop IndLoc® positioning technology, which can prevent such situations. Based on a weak alternating magnetic field, it enables centimeter-precise positioning of various objects as well as precise object detection and communication. IndLoc® can be used where radio-based systems fall short to provide highly precise real-time information on the position, type and quantity of a target object, and if it crosses a boundary. The technology is suitable for a wide range of use cases thanks to its robustness in difficult environments, its simple implementation and its low energy consumption.