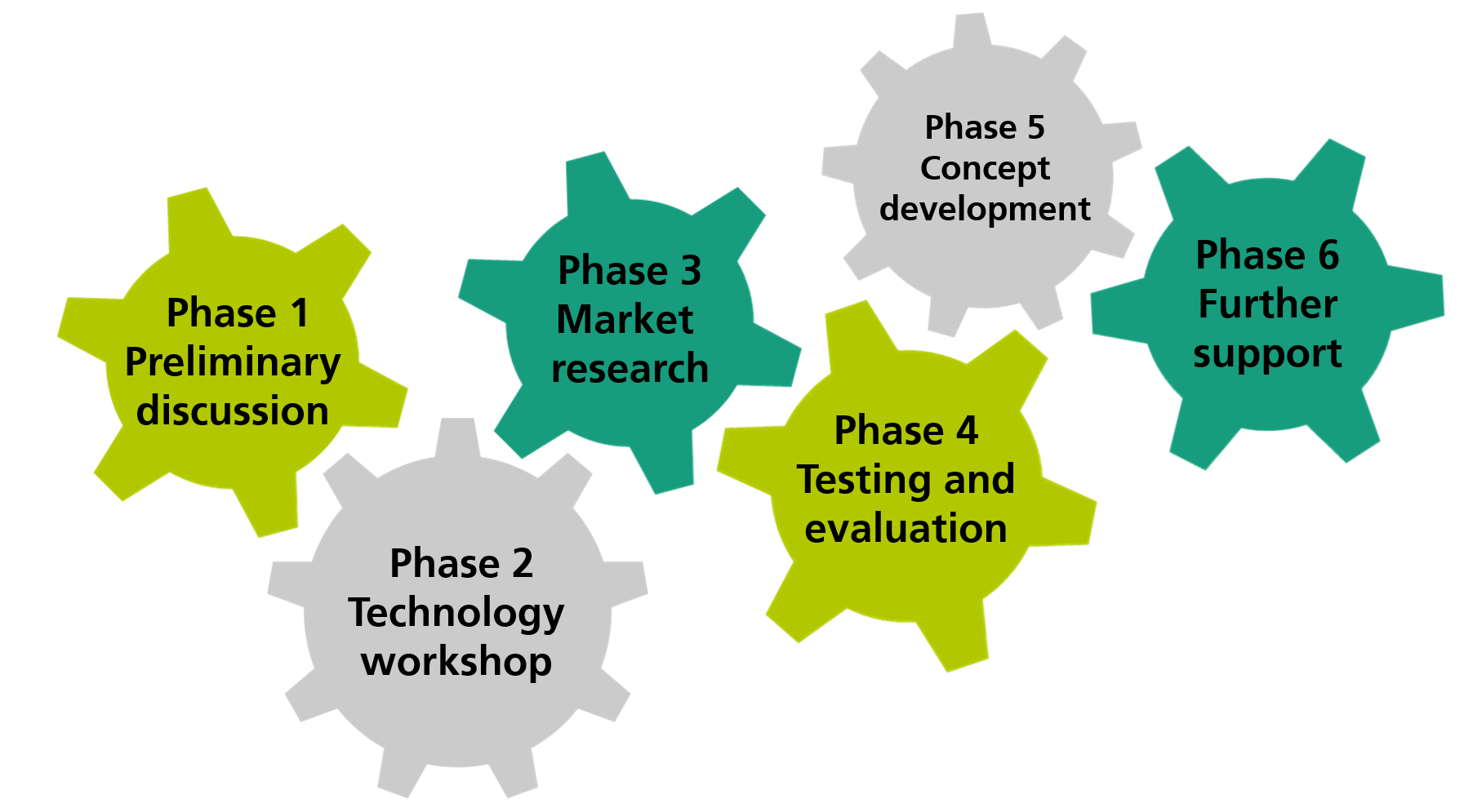

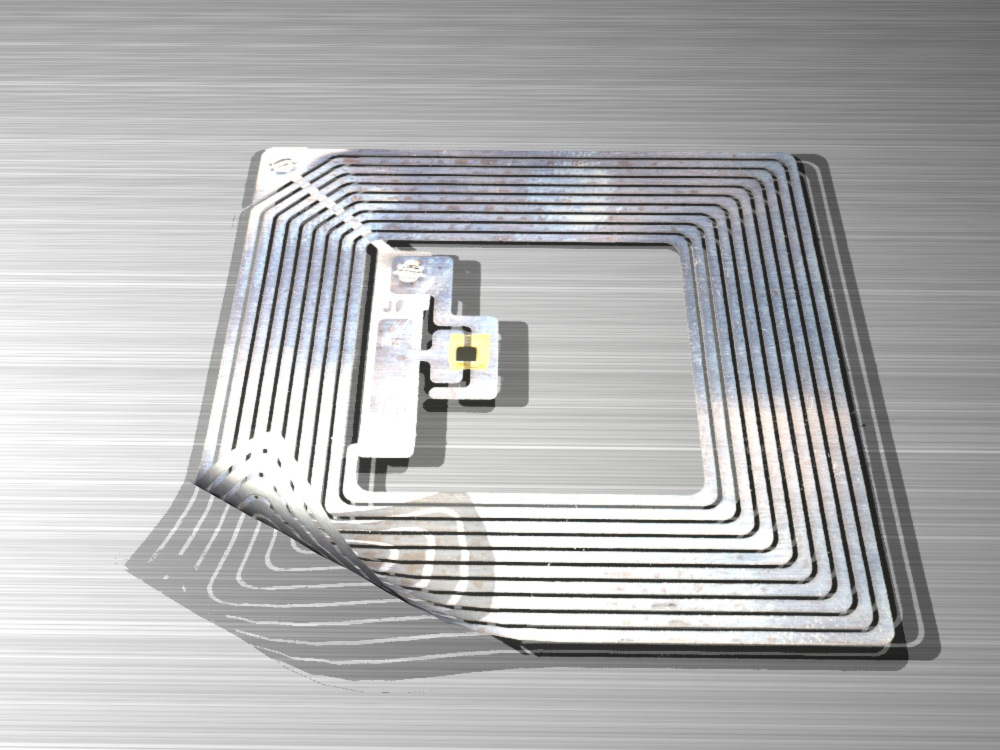

The tracking and transparency of business processes are essential factors for all companies. In order to fulfill these requirements, businesses must be able to respond flexibly and in a holistic manner to the current status of various different processes. Identification technologies are an indispensable part of ensuring maximum transparency in everything from goods receipt to production processes and trade. Radio-frequency identification (RFID) allows the visualization of entire production and supply chains and the maximization of profitability, reliability, and quality. As part of our technology consulting, we will be happy to clarify the extent to which your company would benefit from RFID technology in these respects, as well as examining which technology is best suited to you and resolving any other questions. Fraunhofer IIS puts its comprehensive expertise at your disposal and accompanies you throughout the process of deploying RFID at your company.