Alexander Ennen heads the Application-Specific Methods and Systems department in the Development Center X-ray Technology EZRT at the Fraunhofer Institute for Integrated Circuits IIS. He and his team are developing X-ray systems designed for use on conveyor belts in the fields of electronic waste recycling, mining and detecting foreign objects in food.

How can X-ray technology optimize recycling?

23.11.2020

When Alexander Ennen designs a new X-ray system, he wants it to do more than visualize just the inner structure of the objects. He also wants to know what materials they are made of. To achieve this, he applies the dual-energy method, in which the objects are irradiated with two different X-ray spectra. From the information he gains from the two images, he can then run calculations that allow him to draw conclusions about the material. “The dual-energy method has been in use in medicine and in security checks at airports for some time now,” Ennen explains. “We’re now adapting it for other important applications.”

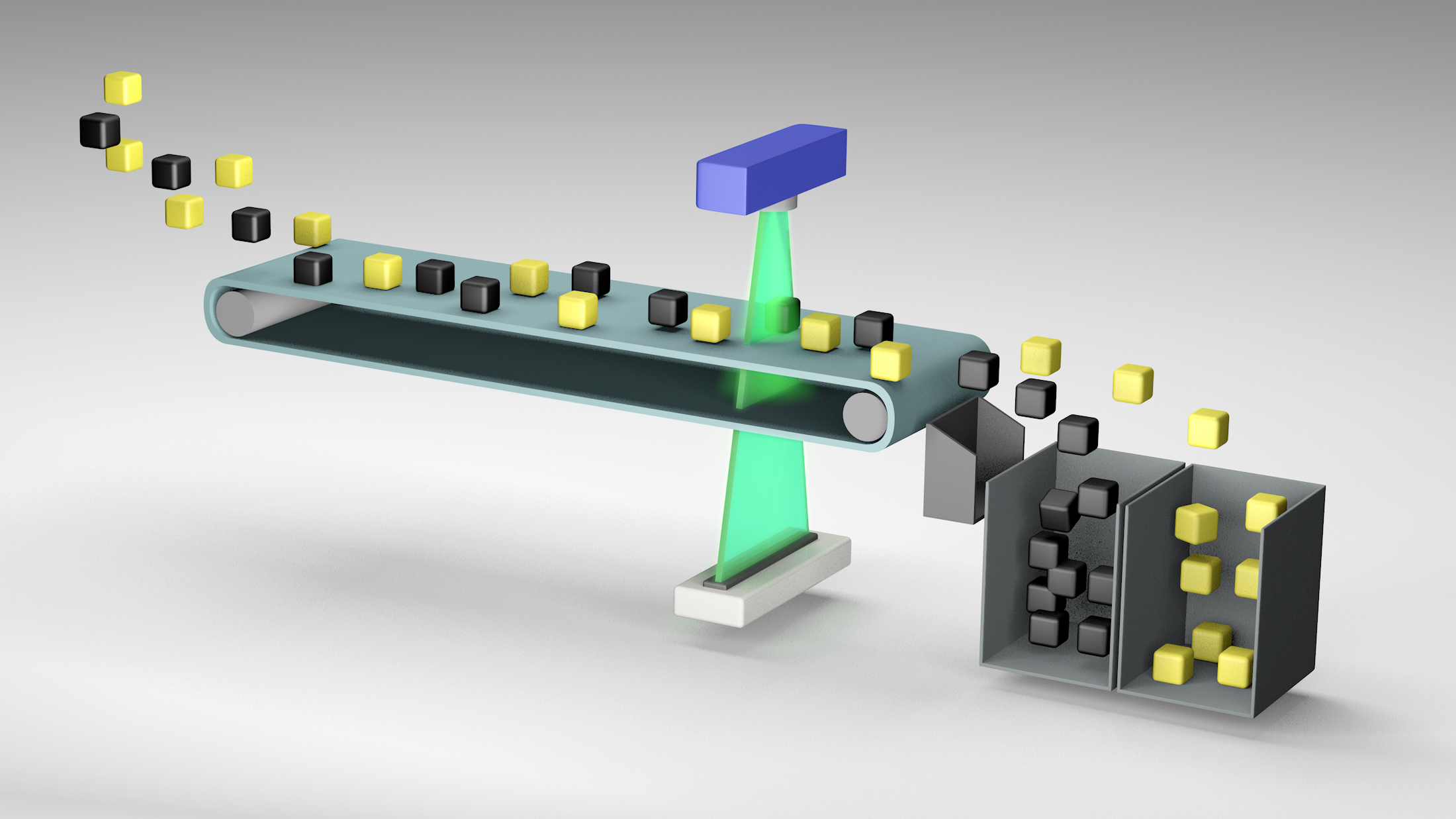

Sorting on the conveyor belt. The dual-energy system helps separate recyclable materials that cannot be identified by purely visual means.

How can we identify recyclable materials in electronic waste?

One area of application with great growth potential is the recycling of electronic waste. The quantities of this waste are constantly increasing and the materials obtained from it are valuable. Together with a mechanical engineering company, Ennen’s team has already established a system for recycling large household appliances such as washing machines or dishwashers. “Shredding these appliances creates flakes the size of a credit card that consist of aluminum, iron, plastic and many other components,” Ennen explains. “With our dual-energy system, we can separate recyclable materials that cannot be identified by purely visual means.”

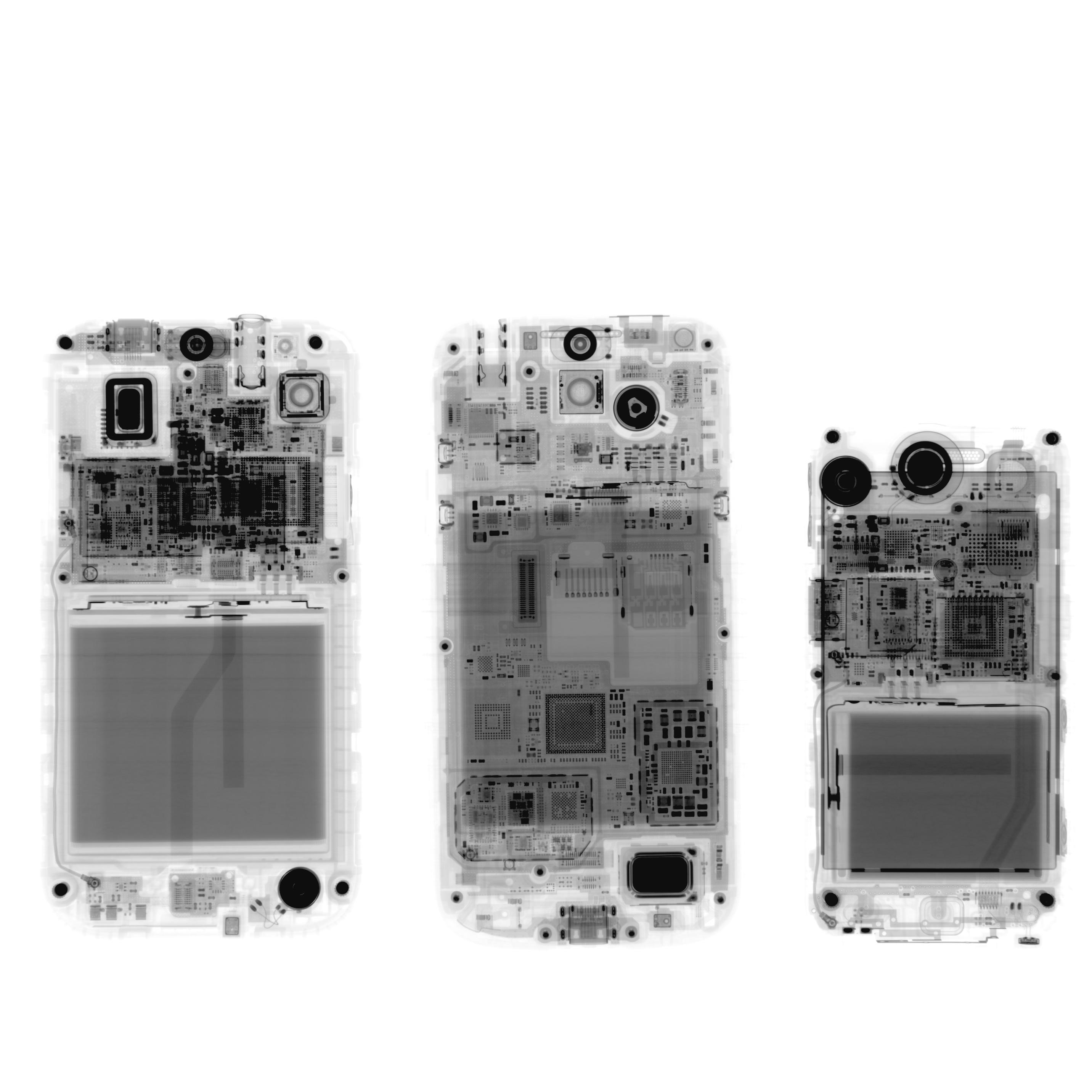

The method can also be used for the recycling of mobile phones, laptops and the like with the main goal of increasing safety in recycling plants. “Batteries that are damaged while the waste is being processed can start to smolder and thus cause fires,” Ennen says. A dual-energy system makes it possible to detect devices with batteries on the conveyor belt and weed them out before they cause damage. These devices could then be dismantled in a controlled atmosphere.

Can X-ray technology make mining more efficient?

In mining, the dual-energy method can be used to X-ray ore and determine its metal content. Fraunhofer EZRT is active in this area as well: a project with Chilean partners is underway to develop a process for measuring the copper content of mined rock. If the content is very low, the rocks are sortet out and not processed any further. This increases the efficiency of the processing and saves on water and energy, resources that are scarce in the mines located high in the Andes.

What benefit is there to X-raying food?

The method is truly universal, as can be shown by its application in the food industry. “Simple radiographic systems are already in use here, but for many problems, they don’t go far enough,” Ennen says. That’s why his team, in partnership with other companies, is building dual-energy X-ray systems that can detect bones in chicken fillets or fish and foreign objects in confectionery. The aim is to have bone-free fish on the table and make recalls of food containing dangerous foreign objects a thing of the past.

Article by Christine Broll