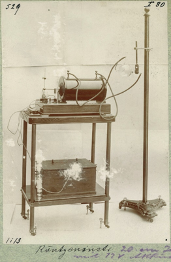

On November 8, 1895, “late in the evening, when not a soul was left in the laboratory to lend a hand,” Würzburg physics professor Wilhelm Conrad Röntgen was preparing one of his experiments. Röntgen wants to test the luminosity of gases by using an electric current to generate gas discharges in a vacuum tube made of glass. He darkens his laboratory, wraps the glass tube in black paper, switches on the power – and his gaze falls on a trivial, seemingly insignificant phenomenon: a fluorescent screen, which happens to be lying on a table next to the light-proof tube, begins to glow green in the darkness of the laboratory. Even wood, paper notebooks and a 1000 page tome cannot stop the strange rays, but platinum and lead can. Röntgen thrusts his hand into the rays and makes probably the most exciting discovery of his life: on the fluorescent screen, he sees the shadows of his own hand bones!

Contact Press / Media

Thomas Kestler

Division Communications

Fraunhofer IIS

Flugplatzstraße 75

90768 Fürth, Germany

Phone +49 911 58061-7611