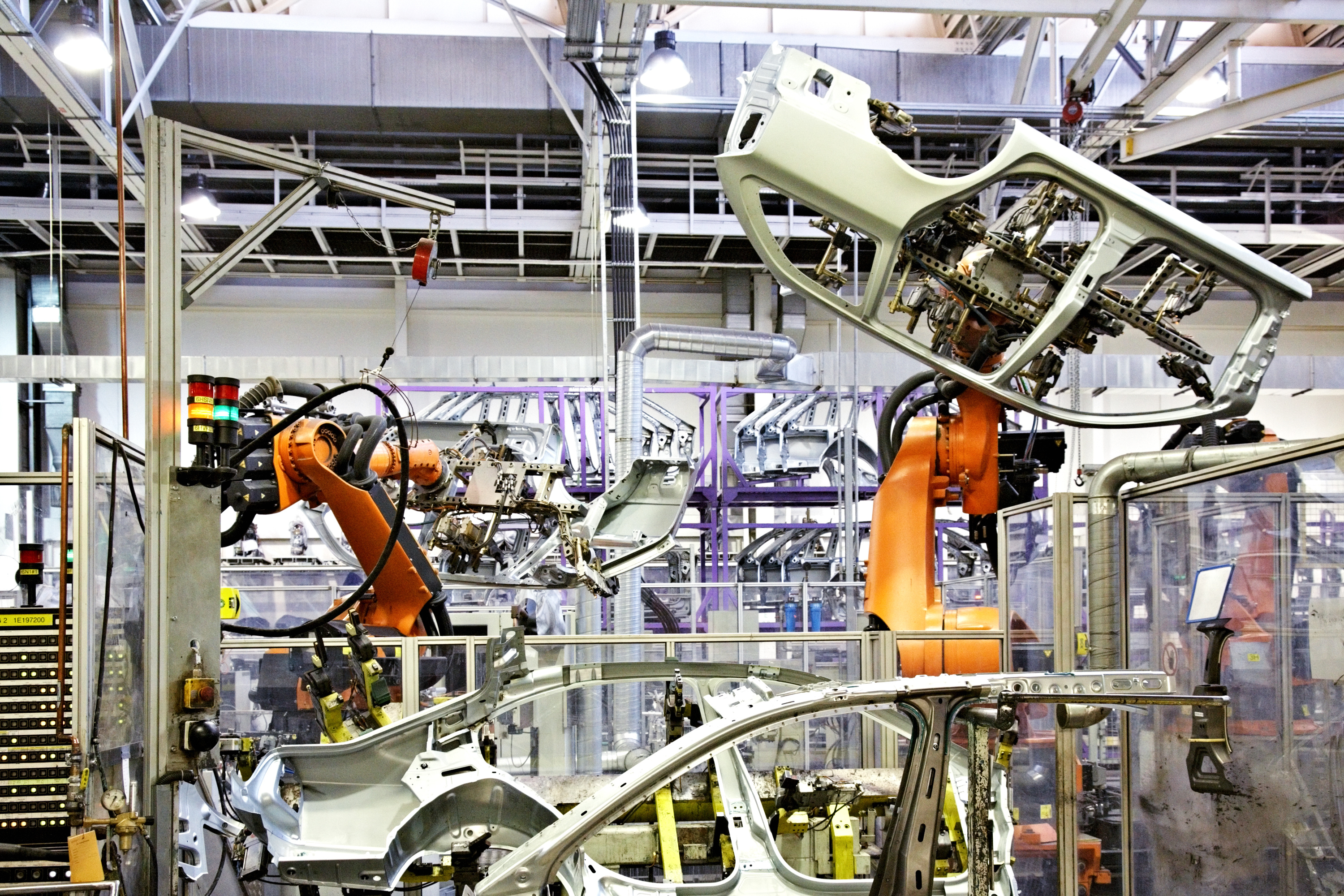

The desire for increased flexibility in production and logistics goes hand in hand with a growing need for continuous positioning of mobile vehicles, products and materials. By collecting, evaluating, and using position-related data, production, assembly and logistics processes can be made sufficiently transparent and automated. In connection with the networking of a large number of machines and sensors, the future of flexible and individualized production is also possible with the help of 5G. The standardization of 5G meets this need by striving for a gradual improvement in positioning accuracy, which takes into account in particular the desire for precise positioning of industry and logistics

Application examples: