Initial situation

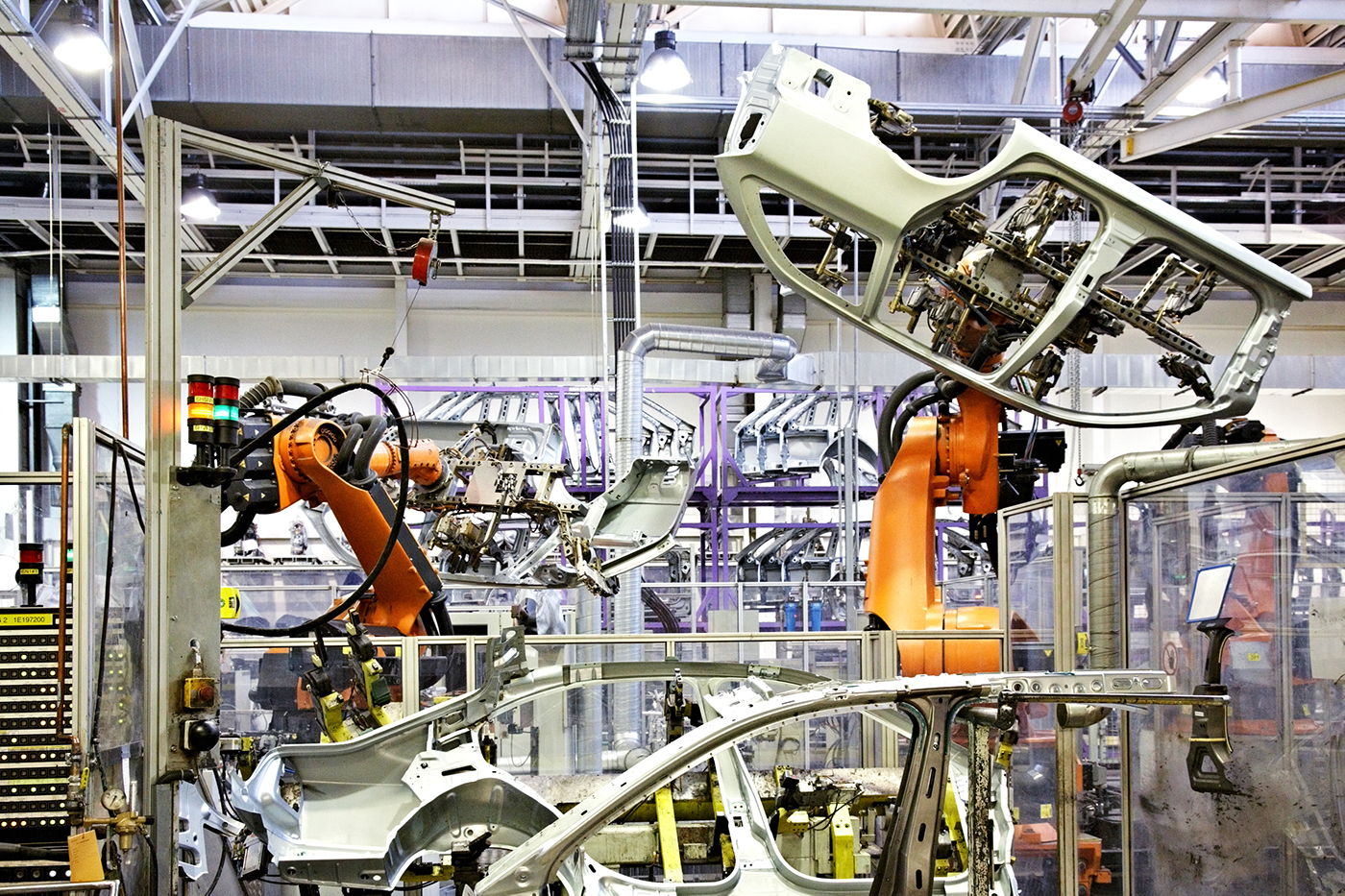

The BMW plant in Dingolfing covers several hundred square meters. The company wanted to monitor an entire production area in an energy-efficient and stable way to find solutions for any problems that occurred. Such issues included finding the reasons for expansion/contraction of gases, liquids or rubber, as well as determining if the environment was having an impact on employee exhaustion and problems with machines. First, BMW turned to PLC data for answers. However, because the data yielded enormous amounts of information and a meaningful evaluation of some parameters was not possible, the company sought out another method. They specifically looked for one that also offered long-term stability and large ranges with low power consumption.

Solution

In the Dingolfing plant, BMW measured temperature, humidity and air pressure over a long period of time using mioty® as the transmission technology.

The production plant houses various machines with many metal parts, contains numerous metallic obstacles and is surrounded by (reinforced) concrete. mioty® is ideal for these difficult environmental conditions, because it can penetrate to great depths while remaining extremely robust against external and intrinsic interference. Setting it up and installing it in the existing infrastructure was also pleasantly uncomplicated.

Benefits

Comparing the air pressure, humidity and temperature data with disruptive events on the machines showed a correlation between an increased number of errors and low humidity as well as between an increased number of errors and sudden changes in air pressure. The highest correlation was seen in the number of errors with low humidity in combination with low temperature.

The analysis also revealed that environmental data for the outdoor area was sometimes more important than environmental data inside the buildings.

Thanks to the results generated by mioty®, BMW was able to take steps to improve the production environment. Furthermore, mioty®’s high scalability means that additional sensors can be easily integrated and more measurements can be included in the search for solutions. The outcome? Higher productivity, lower costs.