Small-angle X-ray scattering and wide-angle X-ray scattering are two methods for analyzing the size, size distribution, electron distribution and structure of nanoparticles, molecules and particle systems on a length scale of about 0.2–250 nm.

X-ray scattering methods

Tabbed contents

Design and function

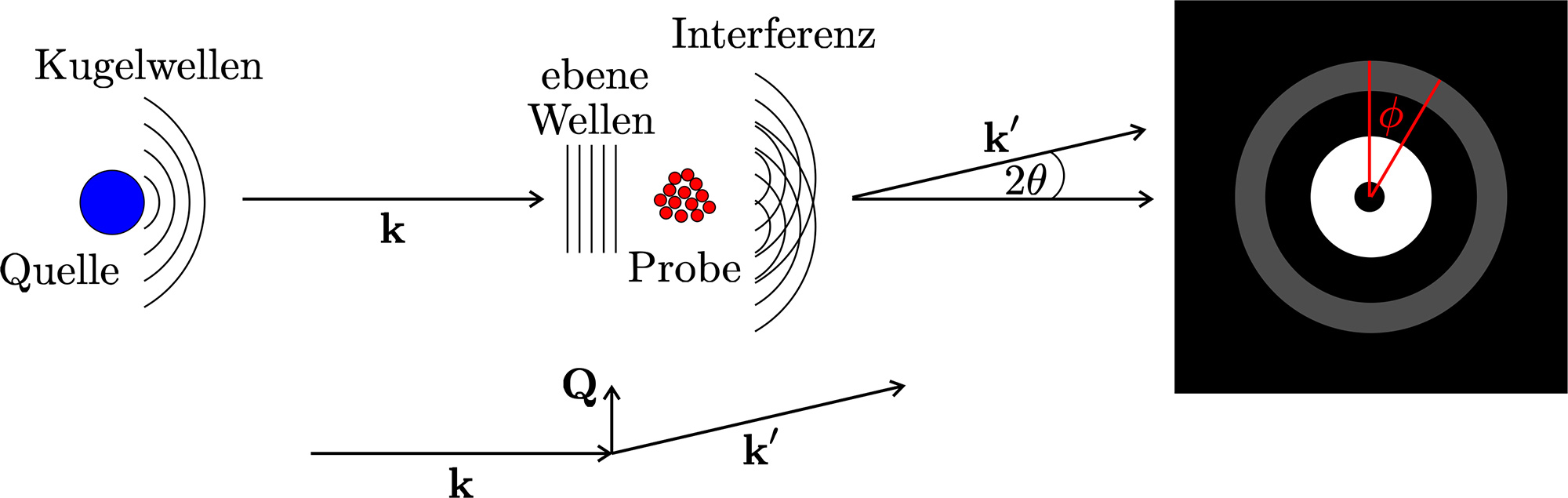

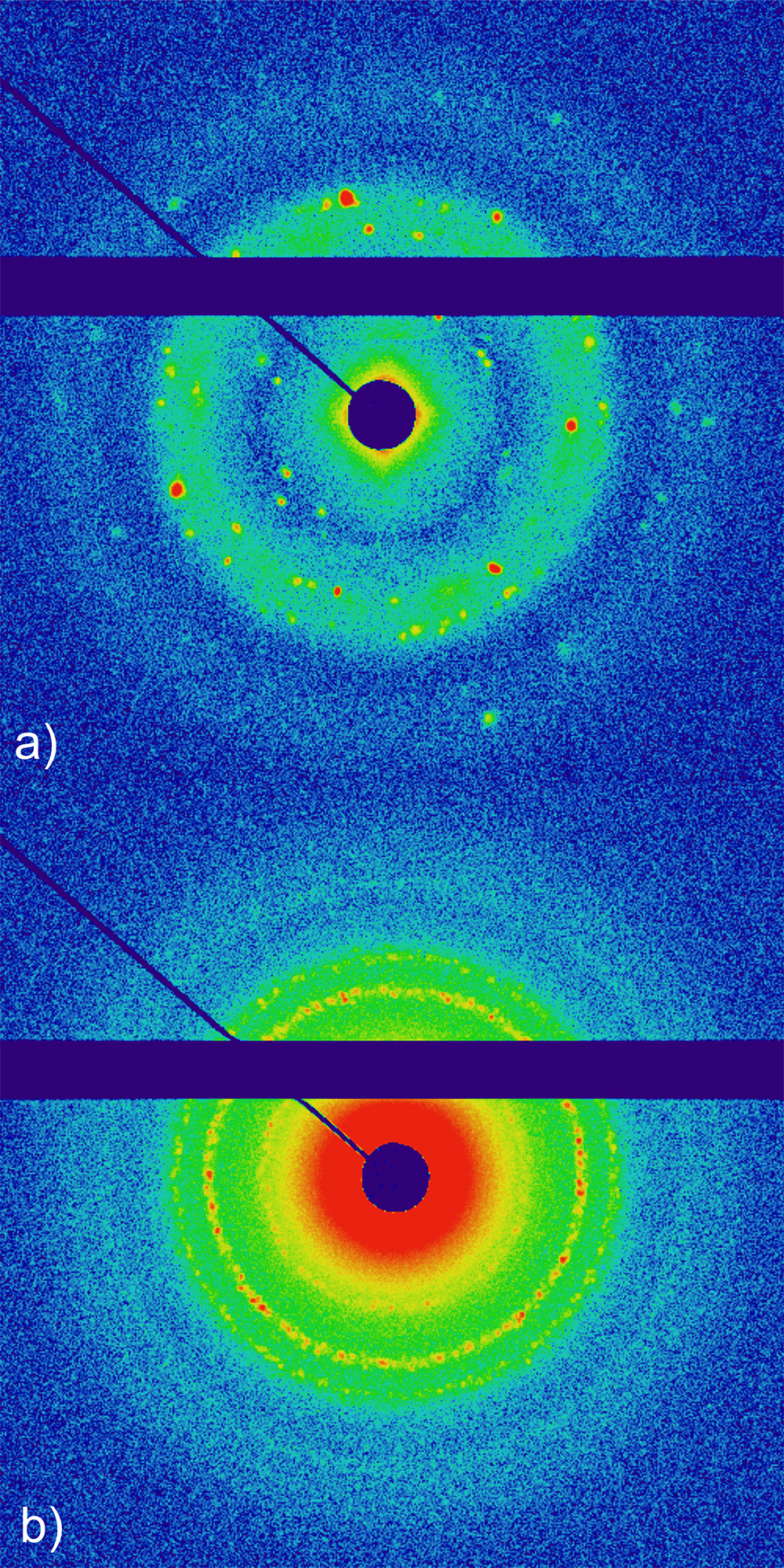

The best-known non-imaging methods of X-ray analysis are diffraction and scattering of the radiation. Bragg’s law demonstrates the reciprocal relationship between structure size and the expected signal: the larger the structure, the smaller the angle of the scattered or diffracted radiation. This is the fundamental basis of small-angle scattering (see Figure 1).

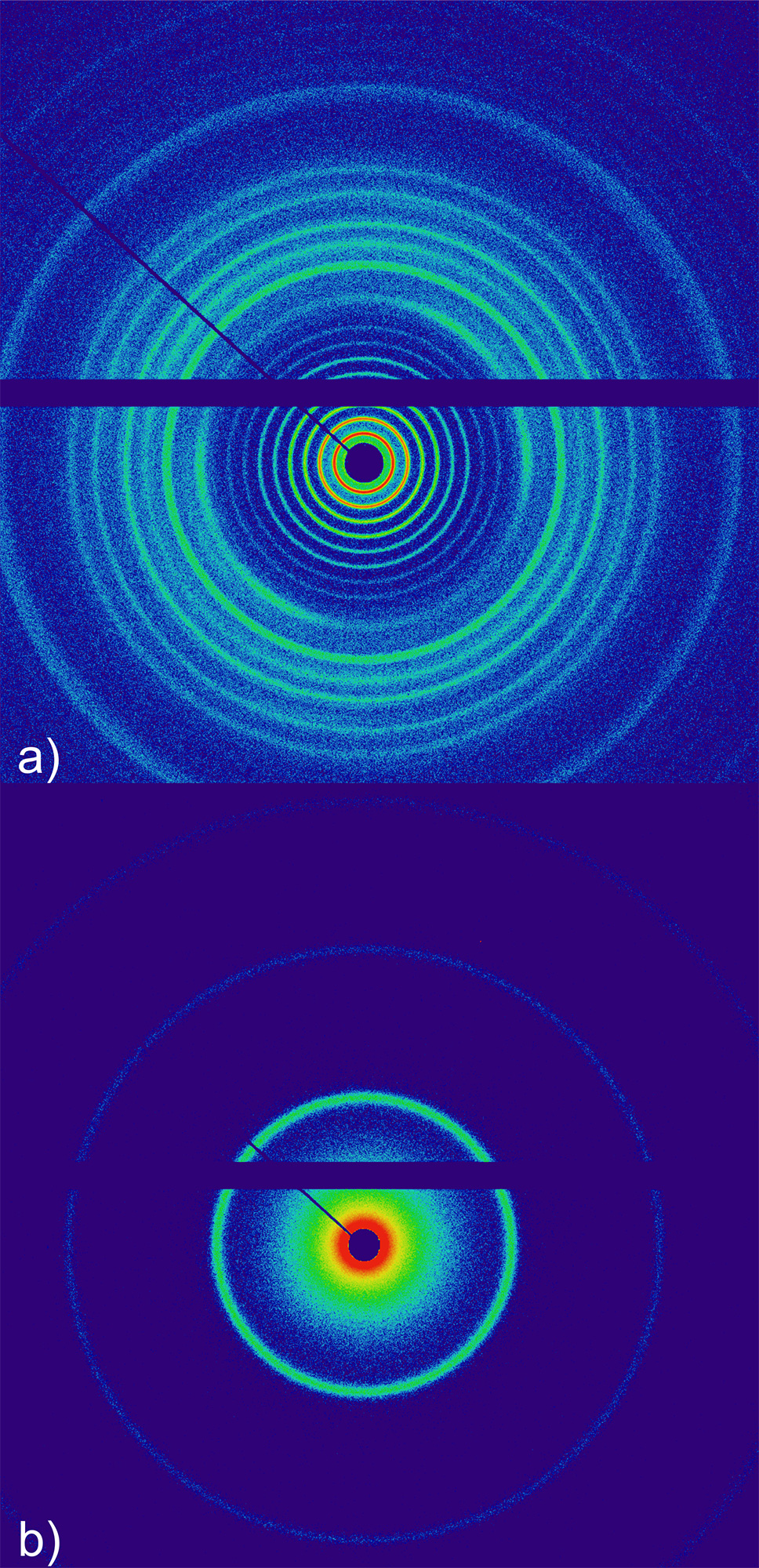

The source generates X-ray radiation, which can be viewed as a plane wave front (k) at a sufficiently large distance. The interference of the spherical waves (k) resulting from the interaction with the sample is visualized on the detector. For analysis and theoretical modeling, the 2D detector image is reduced down to a 1D scatter profile by means of azimuthal integration (as a function of the momentum transfer Q).

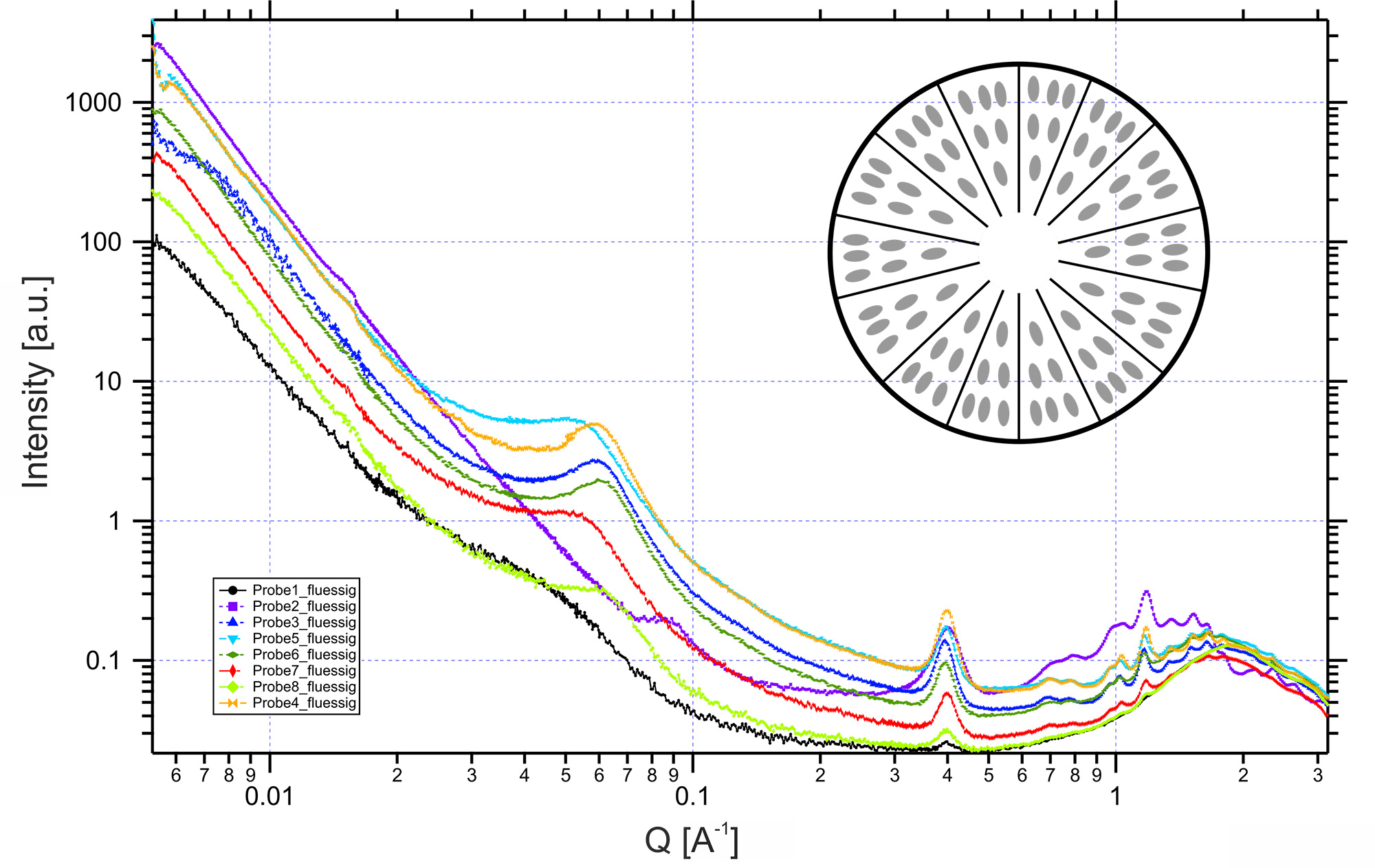

Small-angle X-ray scattering (SAXS) is a common method of material characterization. Possible samples can be tested in a solid state (e.g. powder, alloys, aerogels, wood, collagen) or as a solution (e.g. colloidal solutions, polymer solutions, stabilized nanoparticle solutions, active substance formulations) (see Figures 4 and 5). Essentially, SAXS can be used to obtain information about the

- size and shape of the components in the sample

- structure of the sample

- particle orientation

Unlike in electron microscopy, the results obtained in this way are valid not only for a small random sample. Using the information about a very large number of particles in the sample, it is possible to draw conclusions that are more statistically robust, e.g. about the size distribution.

In addition, the measured intensity can be calibrated so that it corresponds to the differential cross section of the scattering process used. This is called absolute calibration. The calibration standard used at the Chair of X-ray Microscopy (LRM) is a glassy carbon standard (https://usaxs.xray.aps.anl.gov/documentation/glassy-carbon-standard) measured at the Advanced Photon Source (APS, Argonne National Laboratory). This type of calibration enables more complex properties to be determined, such as the electron density distribution in the sample or the hydration level of colloids in a solution.

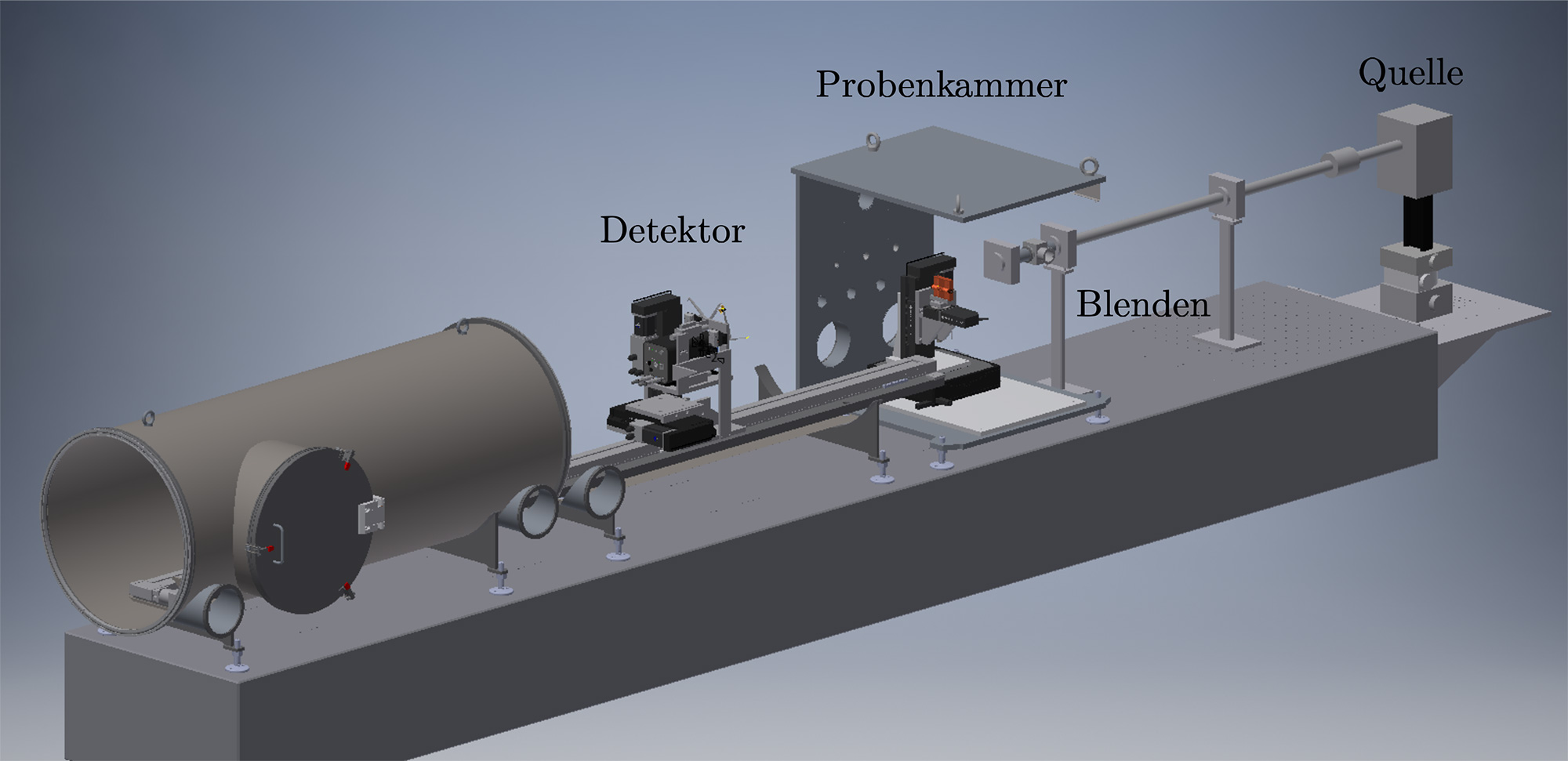

The present SAXS setup at the LRM allows for the distance between the sample and detector to be freely adjusted between 6 cm and 3.5 m. This permits a combination of small- and wide-angle measurements without changing the sample or modifying the setup. Thus, the specifications that the plant can effectively achieve are as follows:

- Angle range: 60° down to a few arcminutes

- Wavelength used: 1.5 Å (Cu-Kα1:Cu-K α2=2:1)

- Effective Q range: 0.005–5 Å-1

- Corresponding sizes that can be tested in real space: 5 Å – 150 nm

With suitable samples, the resulting reduced scattering profiles can deliver five full orders of magnitude of scattering intensity over three full orders of magnitude of momentum transfer Q (see Figure 3). This is comparable to the results that can be achieved using synchrotron radiation.

A range of interchangeable sample environments are available for testing. Samples in a liquid state can be kept at a temperature of between -5 and 80°C during testing, if required.

Areas of application

- Synthetic materials

- Nanoparticles

- Colloids

- Polymers

- Aerogels

- Natural materials

- Collagen

- Wood

- Proteins

Equipment

Wide- and small-angle X-ray scattering (WAXS/SAXS)

- Source: Rigaku microfocus source with rotating anode (power: 1.2 kW)

- Multilayer: Parabolic Göbel mirror for the Cu-Kα line at 1.54 Å

- Collimators: Three motorized collimators, each with four individually movable hybrid blades (single crystals)

- Axes: Detector and sample positioning each have three linear axes; one additional 360° axis for sample rotation

- Sample environments: Mount for up to eight solid samples; capillary mount for up to ten capillaries; heated mount for one capillary (temperature range: -5–80°C)

- Detectors: Dectris EIGER 1M (1035 x 1065 pixels; pixel size: 75 µm)

Advantages and customer value

The variable size of the incident X-ray beam enables very large volumes (compared to the sample diameter) to be analyzed simultaneously. In turn, a direct statistical conclusion can be made about the size distribution of the particles to be analyzed. And, unlike with microscopic methods, samples can be measured in the desired environment, for example stabilized nanoparticles in solution. Additionally, a very small beam can scan larger sample environments to detect local inhomogeneities. In contrast to imaging X-ray methods, small-angle scattering moreover makes it possible to obtain information in the range of a few nm.