Dr. Simon Zabler and his team develop systems for high-resolution computed tomography in the micro- and nanometer range. This allows microscopically fine structures to be examined in three dimensions. His working group is located at the Würzburg location of the Development Center X-ray Technology EZRT.

Is it possible to X-ray microscopic things?

December 17, 2020

When Simon Zabler talks about his first X-ray microscopic images, he waxes lyrical – especially about the aesthetic patterns he was able to make visible in aluminum-silicon alloys. That was almost twenty years ago during his Master’s studies in Grenoble, France. Since then, the physicist has never lost his fascination for the three-dimensional microscopic world.

Who needs micro-computed tomography?

Zabler and his group’s laboratories are located just a few kilometers away from the Institute of Physics, where Wilhelm Conrad Röntgen discovered X-rays in 1895. And the Chair of X-ray Microscopy at the University of Würzburg, with which the Fraunhofer researchers work closely, is right next door. Zabler still uses micro-computed tomography to examine metal alloys today. But this technology’s field of application is much broader. “Micro-CT is primarily used in materials research, especially to examine fiber-reinforced composites or cast components,” Zabler explains. He has even done CT scans of ice cores and milk foam.

“Our goal is to make micro-CT devices more user-friendly,” Zabler says. The devices available commercially are suitable for a broad range of investigations, but must be operated by specially trained staff at the users’ premises. “We design devices for specific applications and can considerably simplify operation through automation,” Zabler says. This lets the market diversify and provides development potential for improved technologies, such as high-throughput scanning, in which hundreds of similar structures are scanned in series and the three-dimensional images are then automatically evaluated on the computer. Uses for this technology include the study of foams, powder or seeds.

Is it possible to combine electron microscopy and computed tomography?

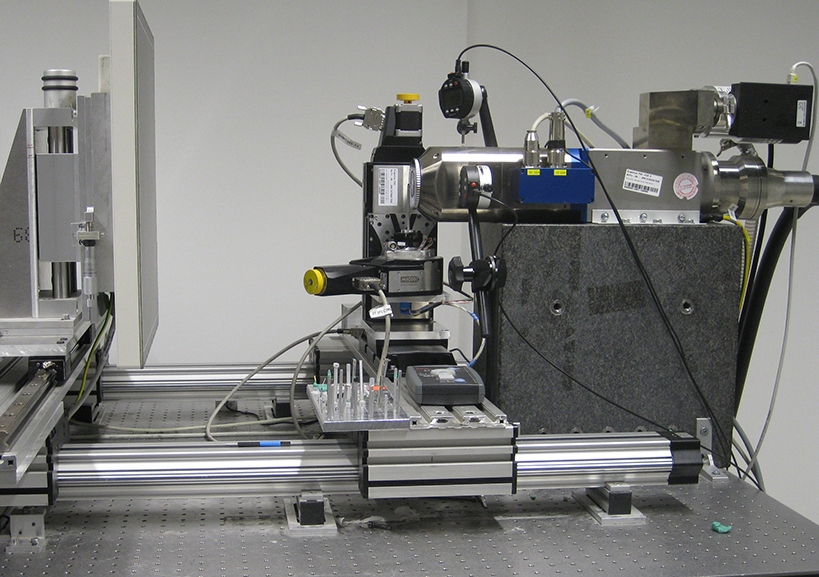

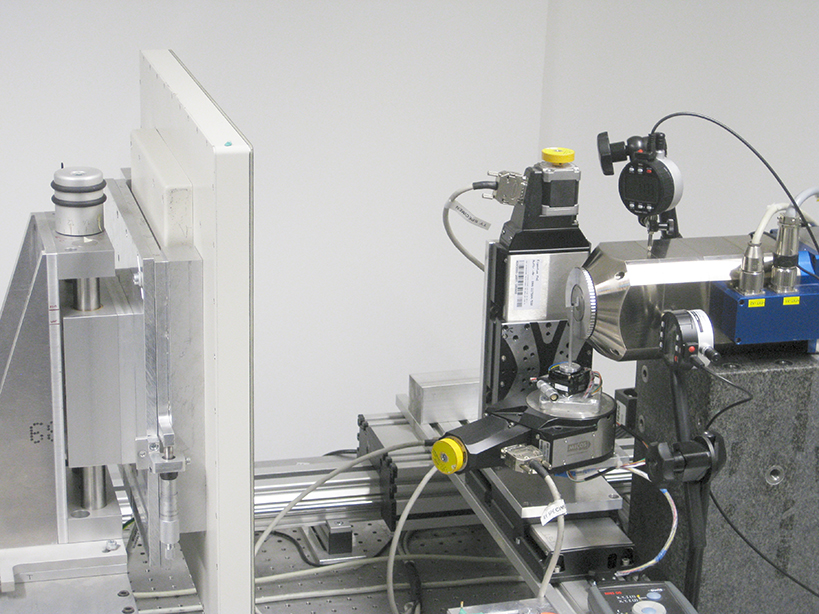

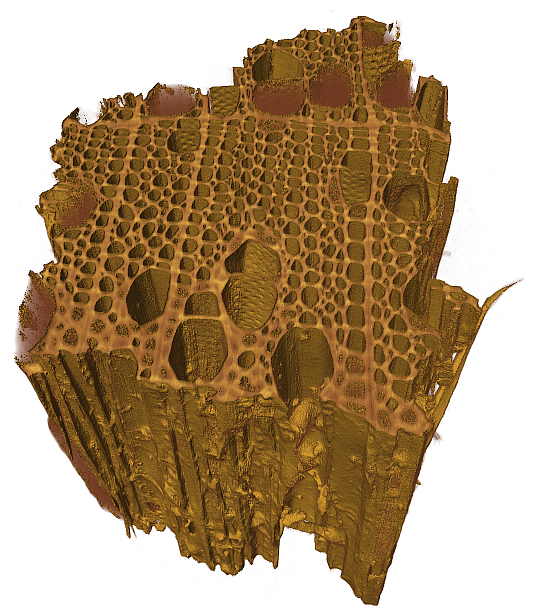

Nano-CT lets Zabler look into the microscopic world in much greater detail. While the resolution of micro-CT is one to two micrometers, nano-CT has a resolution of just 50 nanometers – or 50 millionths of a millimeter. The objects examined with such devices must be no thicker than a hair. This degree of accuracy places huge demands on the devices that Zabler’s team develops. The temperature fluctuations of a normal air conditioning unit alone lead to thermal expansion in the device, which causes camera shake on the scans.

Zabler’s working group has developed two strategies to generate sharp nano-scans nevertheless. One is to operate the devices on a shake-free granite table in a special climate chamber. The second approach is much more sophisticated. It involves using an electron microscope already available at the user’s premises, which already provides the best conditions for a smooth measurement. The nano-CT module with X-ray source and detector is simply hooked up to the existing interfaces and thus integrated into the system. With this combination device, the user can then make both the surface of an object and its three-dimensional structure visible.

How can nano-CT support battery research?

The technology is versatile. For biomedical research, Zabler’s team investigated canaliculi, tiny channels that connect bone cells with each other. Nano-CT images for battery research are also in great demand at the moment. The structures of the anodes and cathodes, which consist of granular powder, are of particular interest here. “Our measurements enable us to better calculate the ion transport in the battery,” Zabler explains, adding that the results are used to optimize the batteries. This is an area in which there is still so much left to do.

Article by Christine Broll