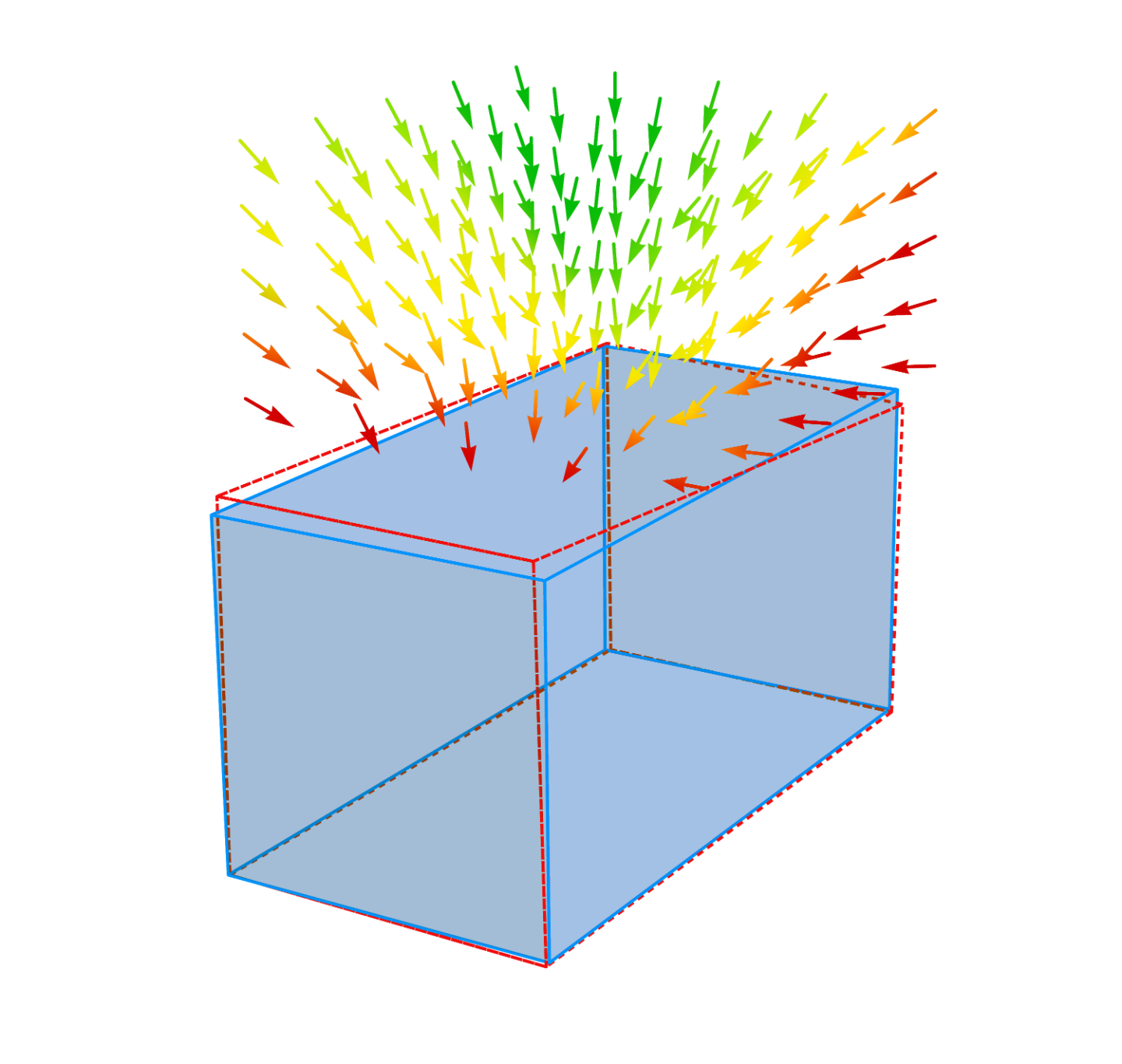

When magnets are mass produced, deviations and errors may occur with respect to your technical specification. In the case of sensors that work based on magnetic fields, faulty magnets may lead to measurement errors or reduced performance in permanently excited electric drives. In magnetic position sensors, the magnet’s position is determined using a precisely defined field curve. This means that any magnetization errors arising from the magnet’s production process can affect how accurately its position can be determined. When it comes to highly efficient electric drives, even small deviations from the parameters in individual magnets lead to fluctuations in torque, thus to unsteady operating behavior and ultimately to reduced service life. These modern use cases show how important it is to know the properties of the magnets used.

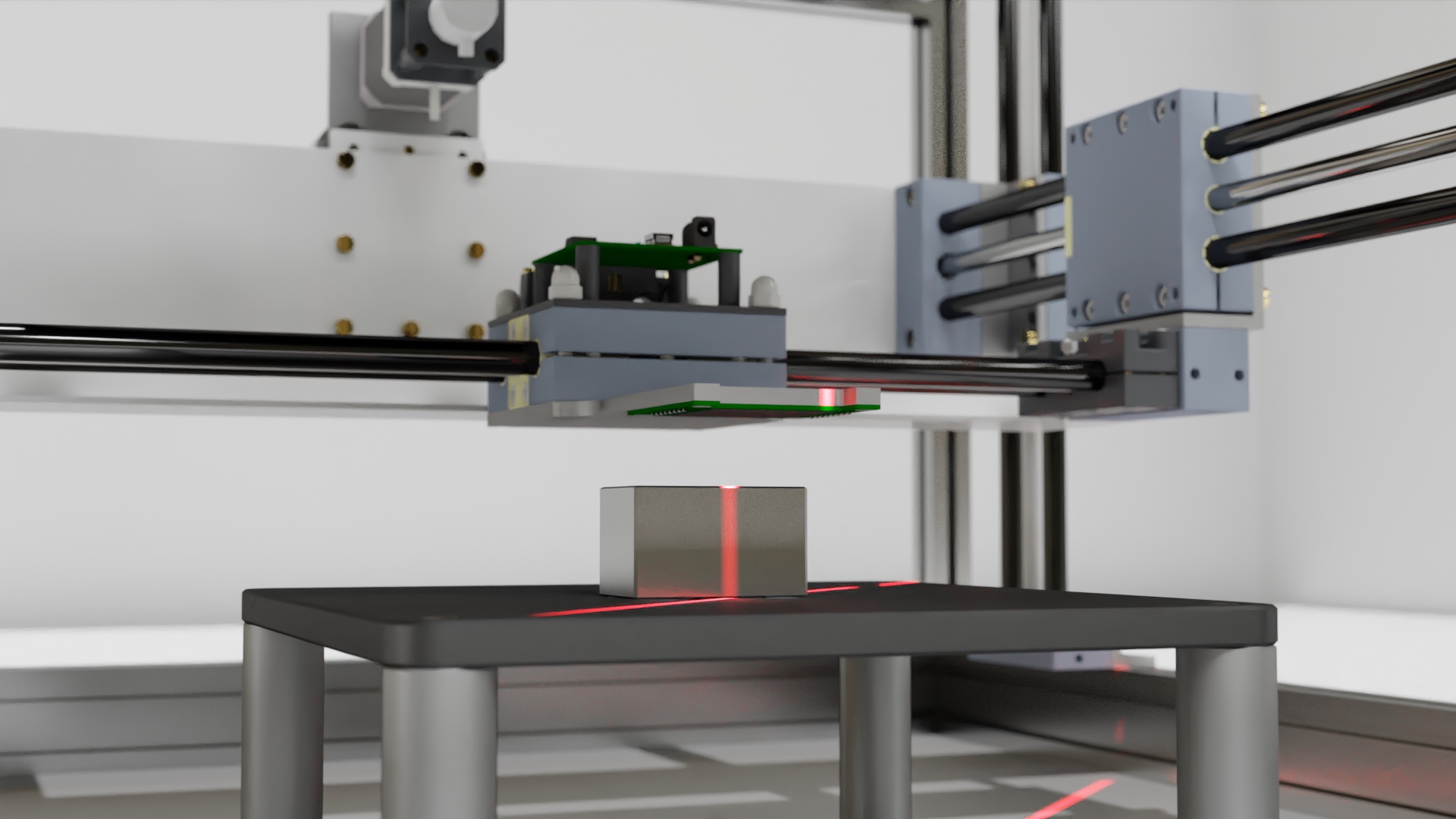

CharaMag - A multisensor system for characterizing permanent magnets

What can the CharaMag multisensor system do?

By combining optical and magnetic sensor technology, the CharaMag multisensor system enables precise detection of a magnet’s position, its three-dimensional shape and the associated spatial distribution of its magnetic field. Since the magnetic and geometric measurements are based on the same frame of reference, it is possible to, for example, analyze how the geometric shape influences the magnetic field, or to use the measurement data to increase the accuracy of the finished position sensor.

Our services

Together with the magnetic field experts from the Integrated Sensor Systems department, we will gladly adapt CharaMag to your use case.

We can also advise and support you with our expertise in optical surface mapping and evaluation as you develop your own specific solution. You can find more details in our service portfolio.