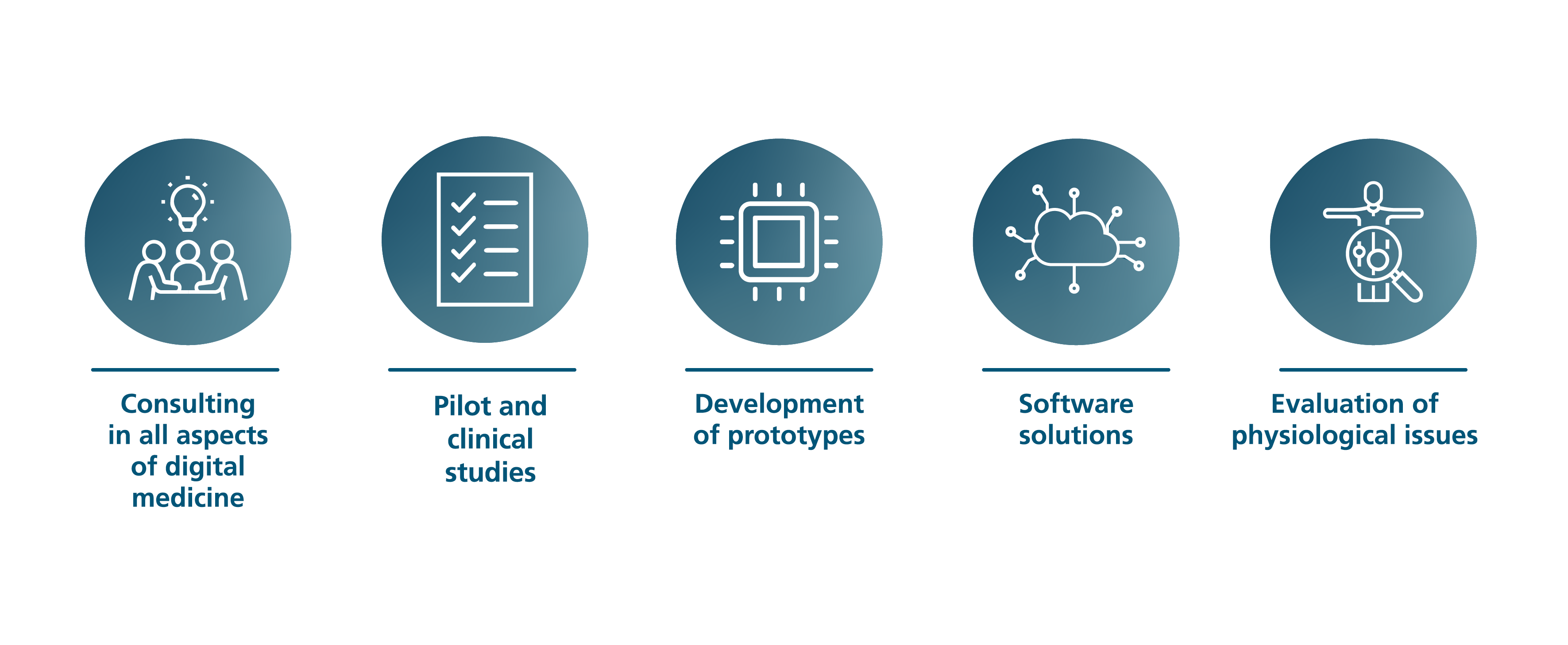

We are shaping the future of digital health by developing customized, product-ready solutions for acquiring and analyzing medical and physiological data.

Thanks to our interdisciplinary expertise and strong connections in the clinical environment, we help our partners gain a scientifically sound, innovative advantage.